What You Need to Know About Ball Check Valves

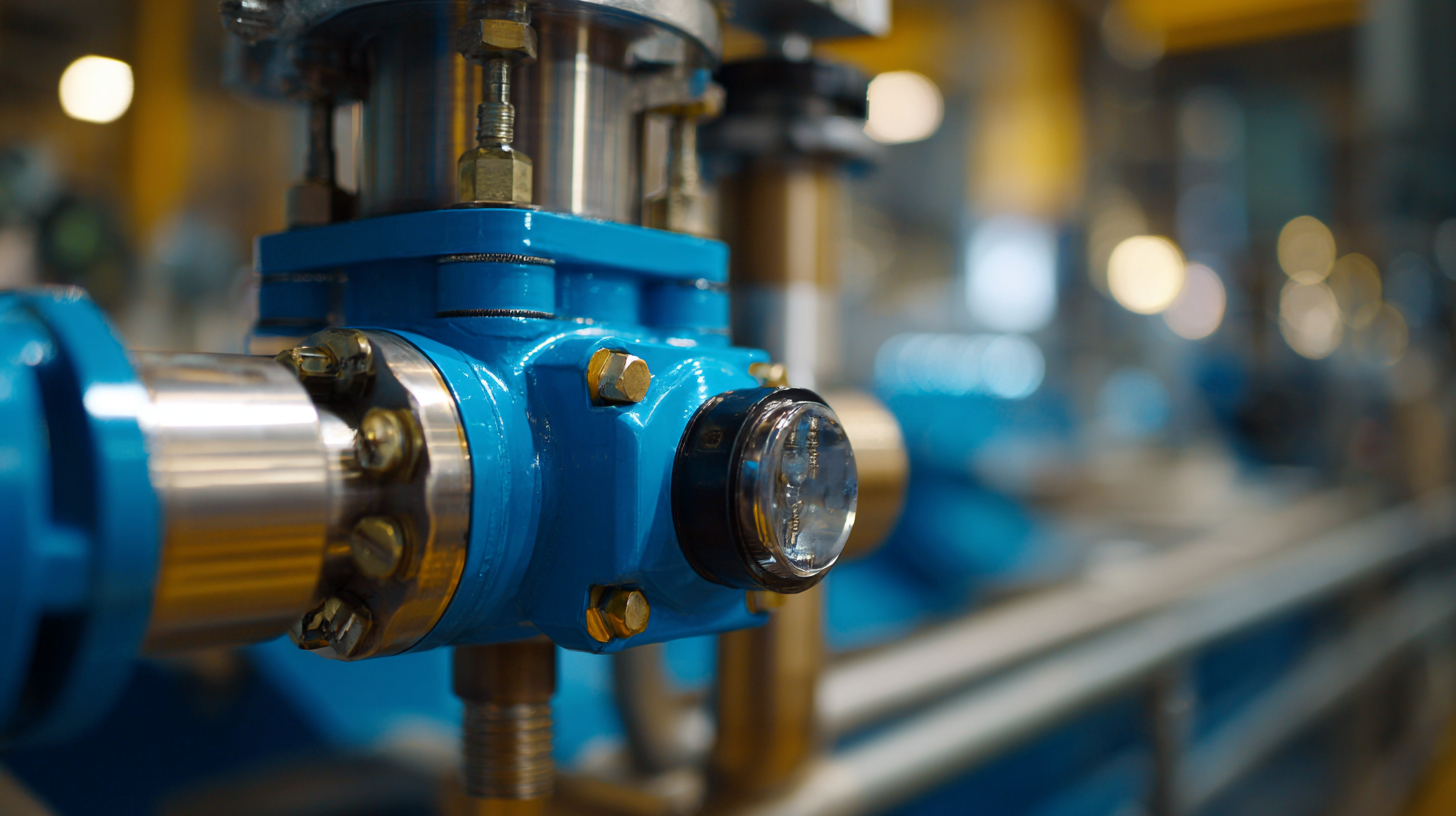

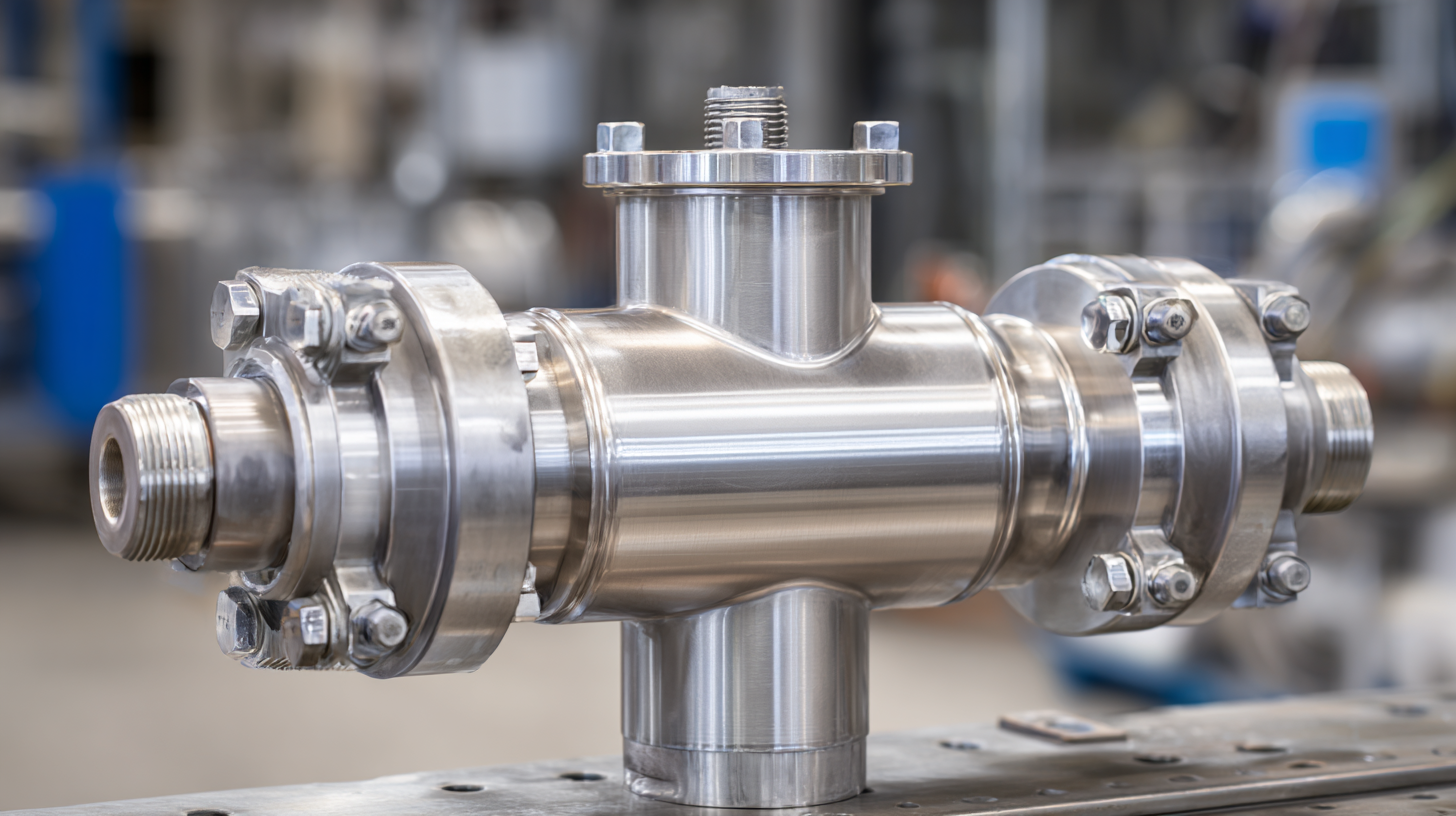

When it comes to fluid control systems, understanding the components that ensure safety and efficiency is crucial. One such important component is the ball check valve, which plays a vital role in preventing backflow in piping systems. This type of valve utilizes a spherical ball mechanism that responds to changes in fluid pressure, allowing flow in one direction while effectively sealing against reverse flow. In industries ranging from water treatment to oil and gas, the reliability of a ball check valve can significantly impact the overall performance of a system.

In this article, we will explore the significance of ball check valves, their operational principles, advantages, and considerations to take into account when selecting and maintaining them, ensuring that you have the essential knowledge to make informed decisions regarding this critical component.

In this article, we will explore the significance of ball check valves, their operational principles, advantages, and considerations to take into account when selecting and maintaining them, ensuring that you have the essential knowledge to make informed decisions regarding this critical component.

Understanding the Functionality of Ball Check Valves

Ball check valves are essential components in various fluid control applications, functioning primarily to prevent backflow in piping systems. Their design incorporates a spherical ball that moves up and down based on pressure differences, allowing fluid to flow in one direction while sealing tightly to prevent reverse flow. According to a report by the Global Check Valve Market, the demand for ball check valves is projected to grow at a CAGR of 5.2% through 2025, driven largely by their efficiency and reliability in fluid systems.

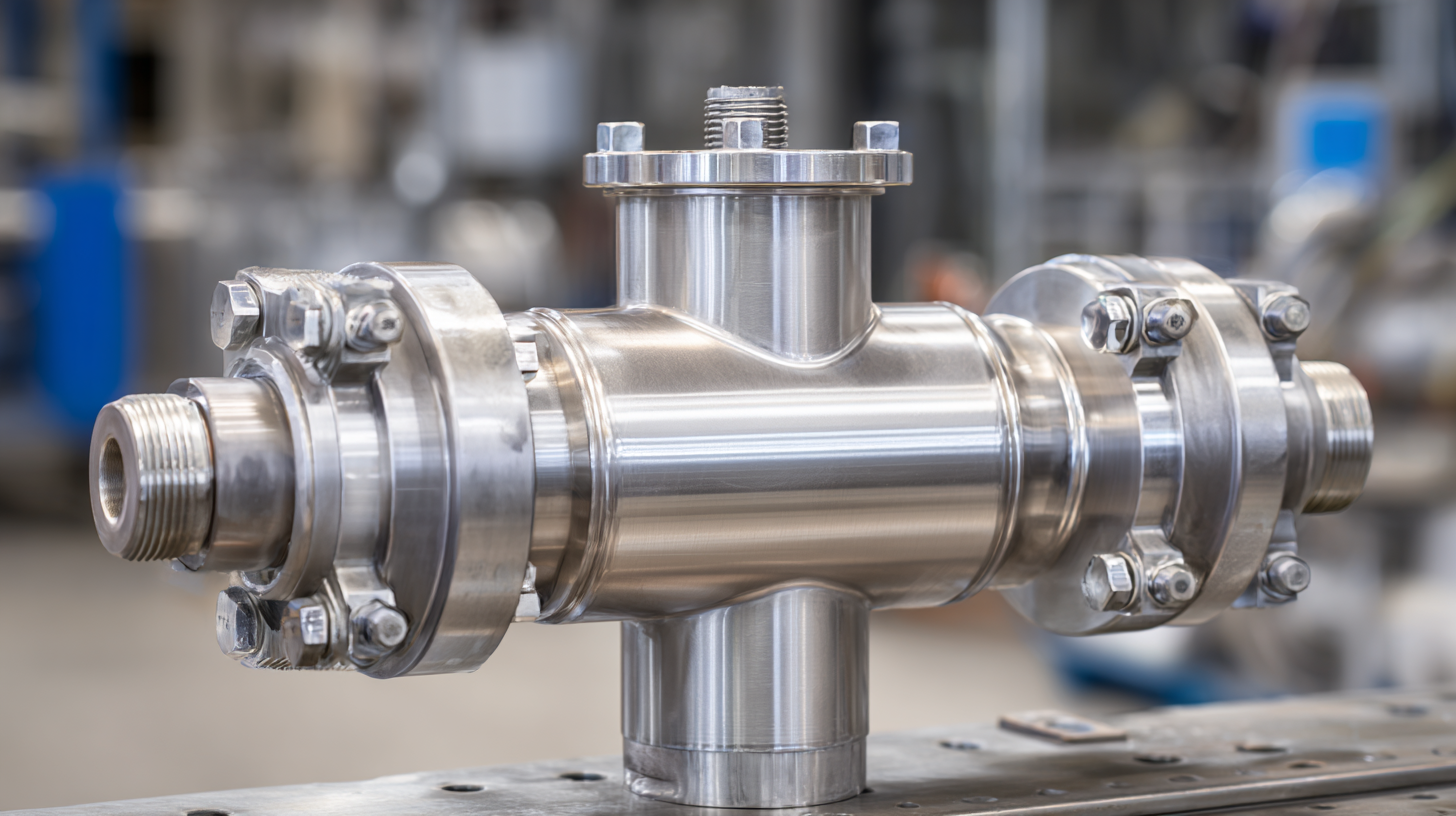

When selecting a ball check valve, it's crucial to consider factors such as material compatibility and pressure ratings. Brass and stainless steel are popular choices for industrial applications due to their durability and resistance to corrosion. Additionally, ensuring proper installation can significantly enhance performance. For instance, installing a ball check valve vertically or at the correct angle facilitates optimal operation, as incorrect positioning can lead to valve failure and costly repairs.

Tips: Always consult manufacturer specifications for the appropriate flow rates and sizes when choosing a ball check valve. Regular maintenance checks can also extend the life of the valve, as keeping the valve clean and clear of obstructions is key to its uninterrupted functionality.

Key Benefits of Using Ball Check Valves in Fluid Systems

Ball check valves are essential components in fluid systems, designed to prevent backflow while allowing forward flow to pass. One of the key benefits of using ball check valves is their robust design, which reliably prevents reverse fluid flow, thereby protecting pumps and other equipment from potential damage.

The spherical ball inside the valve automatically seats against the valve body when back pressure occurs, providing an effective seal that is less prone to wear compared to traditional flap check valves.

The spherical ball inside the valve automatically seats against the valve body when back pressure occurs, providing an effective seal that is less prone to wear compared to traditional flap check valves.

Moreover, ball check valves enhance operational efficiency. Their streamlined design reduces the turbulence in fluid flow, minimizing pressure loss and energy consumption. This feature not only ensures smoother operation but also extends the lifespan of the entire fluid system. In applications where reliability and durability are critical, ball check valves become an advantageous choice, as they require less maintenance and provide consistent performance over time, making them invaluable in various industries.

Common Applications for Ball Check Valves in Various Industries

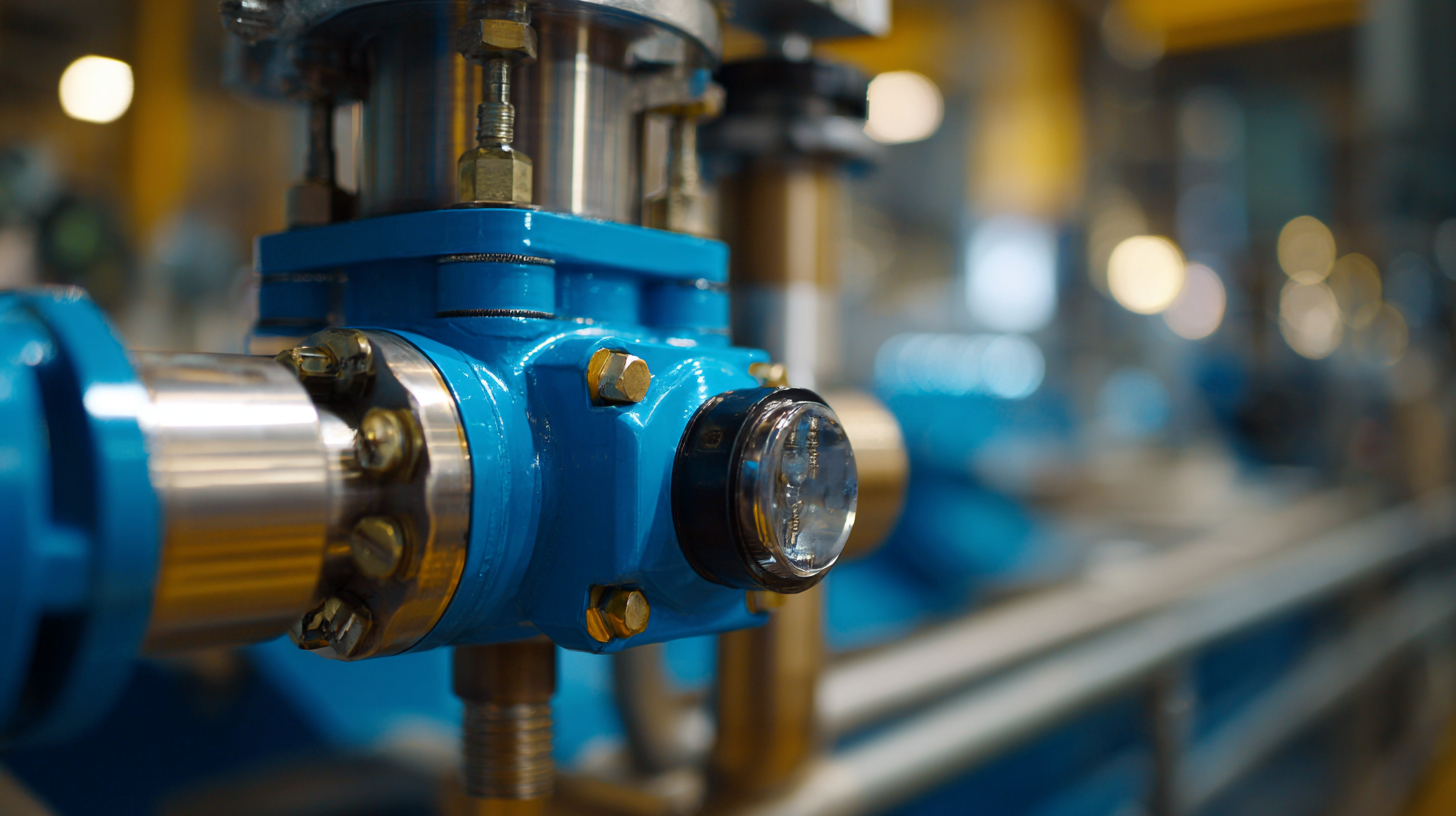

Ball check valves are widely utilized across various industries due to their reliability and efficiency in preventing backflow. In water and wastewater management, these valves are crucial in maintaining system pressure and ensuring that contaminated water does not flow back into clean water sources. Their robust design allows them to handle varying flow rates, making them ideal for treatment plants and municipal water systems.

In the oil and gas sector, ball check valves play a key role in ensuring safety and efficiency during the transportation of hydrocarbons. They prevent backflow in piping systems, which is essential in mitigating spill risks and protecting equipment integrity. Furthermore, in the food and beverage industry, these valves are employed to maintain hygiene and prevent cross-contamination by ensuring that product flow remains unidirectional, thereby safeguarding product quality and consumer safety. The versatility of ball check valves makes them indispensable in multiple applications, demonstrating their critical importance across diverse sectors.

Maintenance Tips to Extend the Lifespan of Ball Check Valves

When it comes to maintaining ball check valves, regular upkeep is essential for ensuring their longevity and optimal performance. One crucial tip is to conduct routine inspections for any signs of wear or damage. Look for leaks, corrosion, or blockages in the valve body. If any issues are detected, addressing them promptly can prevent more significant problems down the line.

Another effective maintenance practice is to keep the valve clean and free from debris. Buildup of contaminants can hinder the valve’s function and lead to premature failure. Using a soft brush and non-corrosive cleaning agents can help ensure that the ball and seat remain in good condition. Additionally, ensure that the valve is installed in an appropriate orientation to prevent unnecessary stress and wear during operation.

Lastly, it's important to monitor the operating conditions regularly. Factors such as pressure and temperature can significantly impact the lifespan of ball check valves. Be sure to adhere to the manufacturer’s specifications and make adjustments if the operating environment changes. Proper adjustments can help maintain the valve's integrity and performance over time.

Maintenance Tips for Ball Check Valves

Troubleshooting Common Issues with Ball Check Valves

Ball check valves are essential components in fluid systems, allowing flow in one direction while preventing backflow. However, like any mechanical device, they can encounter issues that compromise their functionality. One common problem that users face is seat wear due to prolonged use or exposure to abrasive fluids. According to a report by the Hydraulic Institute, 20% of pump failures are attributed to improper valve selection and maintenance, underscoring the importance of regular inspection and timely replacement of worn components.

Another prevalent issue is the buildup of debris within the valve, which can hinder its operation and lead to leaks. Studies indicate that over 30% of system inefficiencies are related to blockages in check valves, demonstrating how critical it is to keep these valves clean and unobstructed. Routine maintenance, including periodic flushing and the use of filters, can significantly reduce the chances of such occurrences, ensuring the ball check valves function optimally and extend their service life. Keeping an eye on these common issues can help mitigate costly downtime and maintain efficient system performance.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

In this article, we will explore the significance of ball check valves, their operational principles, advantages, and considerations to take into account when selecting and maintaining them, ensuring that you have the essential knowledge to make informed decisions regarding this critical component.

In this article, we will explore the significance of ball check valves, their operational principles, advantages, and considerations to take into account when selecting and maintaining them, ensuring that you have the essential knowledge to make informed decisions regarding this critical component.

The spherical ball inside the valve automatically seats against the valve body when back pressure occurs, providing an effective seal that is less prone to wear compared to traditional flap check valves.

The spherical ball inside the valve automatically seats against the valve body when back pressure occurs, providing an effective seal that is less prone to wear compared to traditional flap check valves.