Understanding the Benefits of Actuated Ball Valves in Modern Industrial Applications

In today's rapidly evolving industrial landscape, the need for efficient and reliable fluid control solutions has never been more critical. Actuated ball valves have emerged as a fundamental component in a variety of applications, ranging from oil and gas to water treatment and chemical processing.

According to a recent report by MarketsandMarkets, the global ball valve market is projected to reach USD 12.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.4% from 2020 to 2025.

This growth is largely driven by the increasing demand for automation and the rising focus on energy efficiency in industrial processes. Actuated ball valves offer numerous advantages, including enhanced performance, rapid response times, and reduced operational costs, making them an essential choice for modern facilities seeking to optimize their operations.

As industries continue to embrace automation and smart technologies, understanding the benefits of actuated ball valves becomes crucial for decision-makers aiming to achieve greater efficiency and productivity.

Key Characteristics and Functionality of Actuated Ball Valves

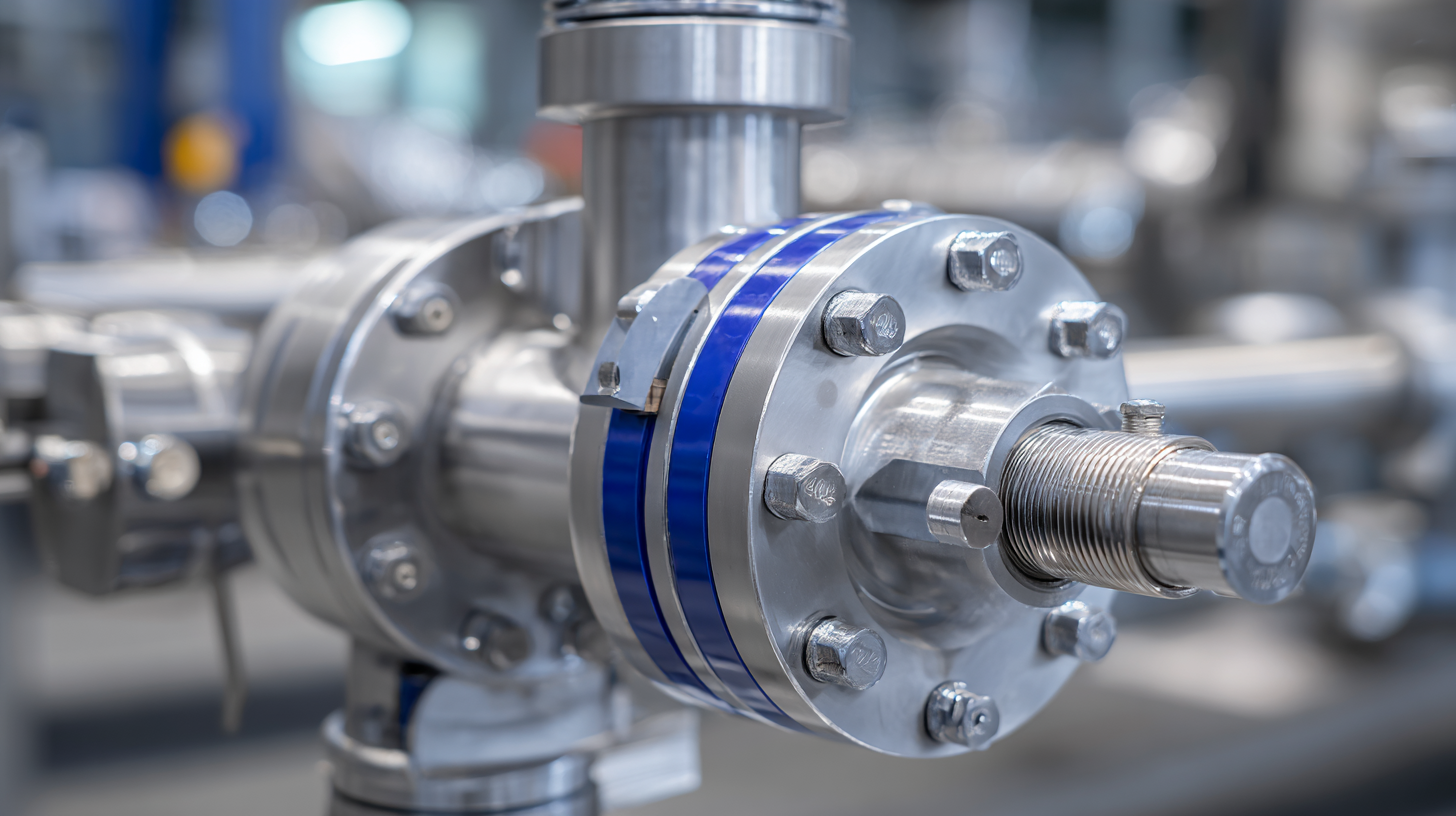

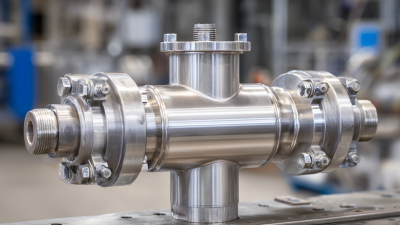

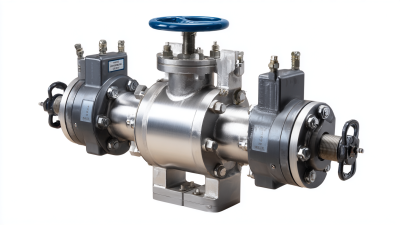

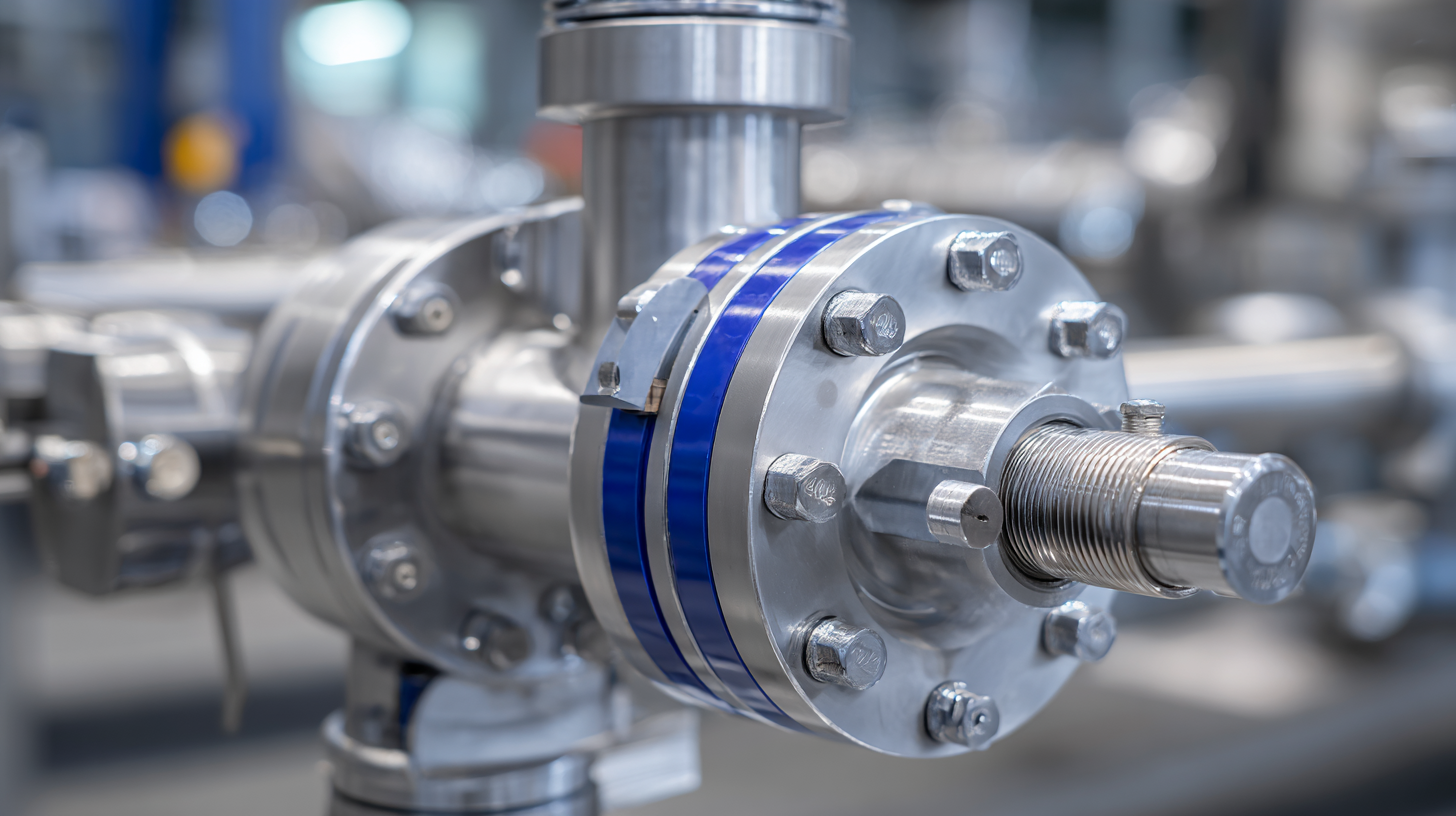

Actuated ball valves play a crucial role in modern industrial applications due to their efficient functionality and reliability. These valves are equipped with an actuator that can be powered by electric, pneumatic, or hydraulic sources, allowing for remote operation and quick response times. This automation enhances the operational efficiency of a system, enabling precise control over fluid flow in various processes. The ability to open or close the valve rapidly helps minimize downtime and can significantly improve safety in critical environments.

Key characteristics of actuated ball valves include their robust construction and ability to handle high pressures and temperatures. The spherical disc design provides a tight seal, which not only reduces leakage but also ensures smooth flow and minimal resistance. Furthermore, these valves are relatively low maintenance due to their simple design and fewer moving parts. They are available in various sizes and materials, making them adaptable for different industrial applications, such as oil and gas, water treatment, and chemical processing. This versatility, combined with their ease of operation, makes actuated ball valves a preferred choice in the modern industrial landscape.

Advantages of Utilizing Actuated Ball Valves in Industrial Settings

Actuated ball valves are becoming increasingly popular in industrial applications due to their unmatched efficiency and reliability. One of the primary advantages of using these valves is their quick operation. With the ability to open or close in just a quarter turn, actuated ball valves significantly reduce the time needed for process control. This rapid response is crucial in industries where timely reactions to pressure changes or flow adjustments can prevent operational hazards or costly downtime.

Another significant benefit lies in their precision and control. The integration of actuators allows for automated and precise handling of fluid flow, contributing to enhanced overall system performance. This precision minimizes the risk of leaks and ensures that the desired flow rates are consistently maintained. Additionally, actuated ball valves can be configured for various control types, including on/off and modulating services, making them versatile tools suitable for a diverse range of industrial applications. Their robustness and ability to handle high pressures and temperatures further enhance their appeal, establishing them as essential components in modern automated systems.

Understanding the Benefits of Actuated Ball Valves in Modern Industrial Applications

Comparison of Actuated Ball Valves with Other Valve Types

In modern industrial applications, actuated ball valves are gaining traction due to their efficiency and reliability compared to other valve types. Their ability to provide quick and precise control of fluid flow makes them ideal for various processes. According to recent forecasts, the control valve market is anticipated to expand significantly, driven by the growing demand for automated systems in industrial settings. Actuated ball valves, in particular, benefit from advanced actuator technologies, including pneumatic and electric options, which enhance their performance in dynamic environments.

When comparing actuated ball valves to traditional valve types such as globe or gate valves, key advantages come to light. Actuated ball valves offer a higher flow rate and lower pressure drop due to their design, which promotes smoother operation. Recent industry reports highlight that the overall market for industrial valves, including all types, is being shaped by technological advancements, with actuated systems becoming increasingly favored for their simplicity and reduced maintenance needs. As industries continue to seek improved efficiency, the role of actuated ball valves will likely expand, solidifying their position in modern fluid control applications.

Understanding the Benefits of Actuated Ball Valves in Modern Industrial Applications - Comparison of Actuated Ball Valves with Other Valve Types

| Valve Type |

Operation Method |

Key Advantages |

Common Applications |

| Actuated Ball Valve |

Electric/Pneumatic |

High flow rate, quick operation, low torque |

Water treatment, oil & gas, chemical processing |

| Globe Valve |

Manual/Electric |

Good throttling capability, tight seal |

Steam, water, oil & gas |

| Gate Valve |

Manual/Electric |

Minimal pressure drop, full flow |

Pipeline systems, water supply |

| Check Valve |

Automatic |

Prevention of backflow, low maintenance |

Wastewater, fuel lines |

Applications of Actuated Ball Valves in Various Industries

Actuated ball valves play a crucial role in various industrial applications due to their versatility and reliability. In the oil and gas sector, these valves are essential for controlling the flow of fluids in pipelines and processing plants. They can operate remotely, allowing for safer and more efficient management of hazardous materials. The speed at which these valves open and close helps maintain optimal pressure levels, reducing the risk of leaks or accidents.

In the water treatment industry, actuated ball valves facilitate precise flow regulation during the filtration and chemical dosing processes. Their robust design withstands corrosive environments, making them ideal for managing water quality and distribution. Additionally, in the pharmaceutical sector, these valves ensure sterile conditions in production lines by minimizing the risk of contamination during fluid transfers. Their automated operation also enhances efficiency, reducing the need for manual intervention and allowing for streamlined processes in critical applications.

Future Trends and Innovations in Actuated Ball Valve Technology

As industries continue to evolve, actuated ball valves are experiencing significant advancements that enhance their functionality and efficiency. Future trends indicate a shift towards smart actuated ball valves equipped with IoT technology, allowing for real-time data monitoring and predictive maintenance. This integration facilitates improved decision-making processes and minimizes downtime, leading to increased operational efficiency. Moreover, the use of advanced materials and coatings in the construction of these valves ensures better durability and resistance to wear, further extending their service life in demanding industrial environments.

Innovations in actuator design also play a crucial role in the future of actuated ball valves. Developments in electric and pneumatic actuators are leading to more energy-efficient operations, reducing the overall carbon footprint of industrial facilities. The trend towards modular designs enables easier maintenance and quicker replacements, which is an essential factor for industries aiming for agility and responsiveness. As automation becomes increasingly prevalent, the ability for actuated ball valves to seamlessly integrate with sophisticated control systems will reinforce their position as indispensable components in a wide range of industrial applications.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.