2026 Best Ball Check Valve Features and Buying Guide?

When considering a ball check valve, it's essential to know its features. The right valve can significantly impact fluid flow and system efficiency. A quality ball check valve prevents backflow, ensuring smooth operation in plumbing and industrial applications.

Choosing the best model requires understanding important factors like material and size. Many options exist, but selecting the most suitable one can be overwhelming. Keep in mind, not all valves feature the same durability or performance.

As you explore the market, be aware of potential pitfalls. Some valves marketed as high-quality may not meet your needs. Always verify the specifications before purchasing. A ball check valve plays a crucial role in many systems, making informed choices vital for optimal functionality.

2026 Best Ball Check Valve Overview and Applications

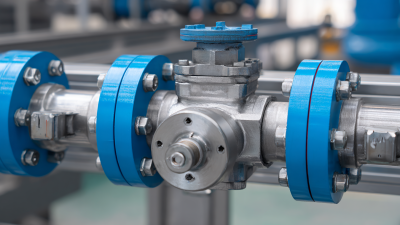

Ball check valves play a crucial role in various industries. Their primary function is to prevent backflow in piping systems. This is essential in applications like water supply, wastewater management, and industrial fluid transport. When fluid flows in one direction, the ball inside the valve lifts, allowing passage. If the flow reverses, the ball seals against the seat, stopping any backflow.

These valves come in many designs and materials. Common choices include brass, stainless steel, and plastic. Each material suits different environments, whether corrosive or under high pressure. Installing the right valve can reduce costly leaks and downtime. However, users often overlook maintenance. Periodic inspections are necessary to ensure they function properly. Dust, debris, or wear can compromise their effectiveness.

In practical applications, ball check valves can be found in home plumbing, heating systems, or irrigation setups. They are vital for ensuring efficiency and protecting equipment. It's important to select a valve designed for specific conditions. Overlooking aspects like pressure ratings may lead to failures. Each environment poses unique challenges, and choosing correctly requires thoughtful consideration.

Key Features to Consider When Choosing a Ball Check Valve

When selecting a ball check valve, several key features are paramount.

Size and materials play a critical role in ensuring

durability and performance. Consider the application environment.

Corrosive substances require materials like stainless steel or PVC.

The wrong choice can lead to failure. Notably, a study from the Fluid Control Institute

highlights that over 40% of valve failures result from material incompatibility.

Flow rate is another essential factor. High flow

demands necessitate a valve that can handle increased pressure. Check the specifications

carefully. The wrong flow rate can impact system efficiency. Hydraulic professionals

recommend verifying the flow coefficients of various models before making a decision.

Tips: Before purchasing, always consult technical datasheets. They offer

invaluable insights into compatibility and performance. It's better to ask experts

than to guess. Additionally, evaluate the warranty and customer support.

A solid warranty can reflect the manufacturer's confidence in their product. Remember,

investing time in research pays off.

Materials Used in Ball Check Valves: Pros and Cons

When choosing ball check valves, the materials significantly impact their performance. Common materials include brass, stainless steel, and PVC. Brass offers excellent corrosion resistance, making it suitable for many applications. However, it can be heavy and may not withstand extreme temperatures.

Stainless steel is another popular choice. It provides superior strength and durability. Yet, it can be more expensive and may be prone to certain types of corrosion. PVC is lightweight and cost-effective, but it may not withstand high-pressure situations. Knowing these traits helps in making informed decisions.

**Tips:** Always consider the application. What works for one use may not suit another. Check the pressure and temperature limits of each material. A mismatch could lead to failure.

Be aware of the limitations. For instance, while PVC is affordable, it might degrade under UV light. That could cause issues over time. Each choice has its pros and cons, so evaluate your needs carefully. Understanding these factors leads to better selections in ball check valves.

Comparison of Materials Used in Ball Check Valves

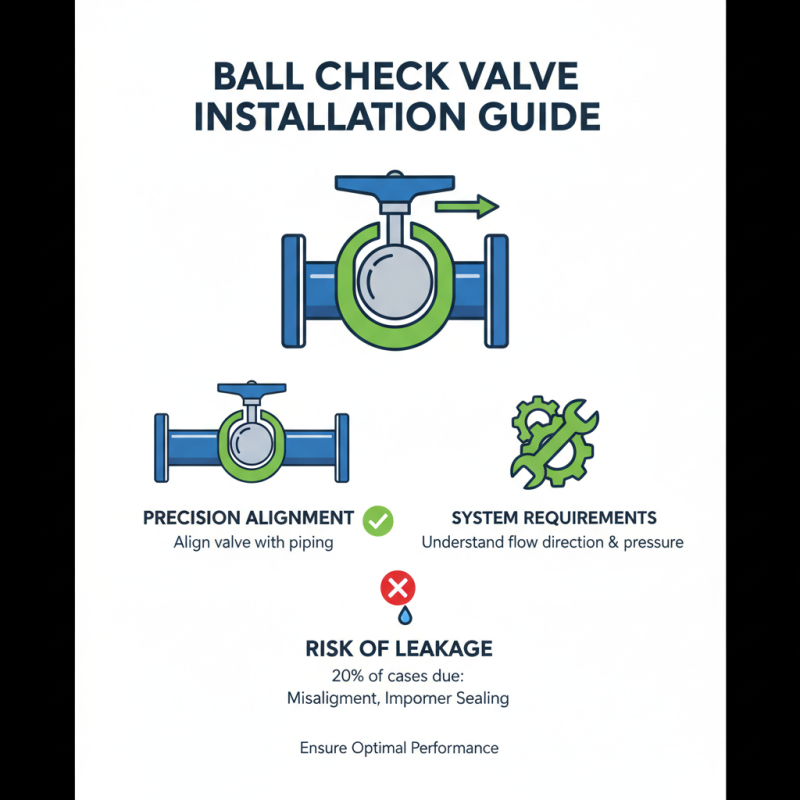

How to Properly Install a Ball Check Valve

Installing a ball check valve requires precision and understanding of system requirements. The valve should align with the piping to ensure optimal performance. According to industry data, incorrect installation can lead to leakage in 20% of the cases. This issue often stems from misalignment or improper sealing.

Start by ensuring the valve is oriented correctly. The flow direction must match the arrow on the valve. In systems with fluctuating flows, secure the valve at both ends. Tightening should be balanced, preventing excessive force that can warp the valve body. Remember that using thread sealant is crucial to avoid leaks.

Check valve materials play a role in durability. For instance, PVC is popular for water systems, but it can be less resilient than metal alternatives. Consider factors like temperature and chemical exposure. Some reports suggest improper material choice can lead to failure in up to 15% of installations. Always reflect on these details to enhance the valve's longevity and functionality.

Maintenance Tips for Longevity of Ball Check Valves

Ball check valves are crucial in many systems. They prevent backflow, ensuring fluid flows in one direction. However, they can wear out over time. Regular maintenance is vital for longevity.

To extend the life of a ball check valve, routine inspection is essential. Check for leaks and signs of wear. Make sure the valve is free from debris. Often, dirt can accumulate and impede movement. Cleaning is straightforward but must be done carefully. Using a soft cloth helps; avoid harsh chemicals.

Lubrication is also important. Use the right lubricant sparingly; too much can cause issues. Over time, seals can deteriorate. Inspect and replace them periodically. Monitor performance regularly. If you notice unusual sounds or vibrations, it’s time for a closer look. A proactive approach can save time and prevent costly repairs later.

2026 Best Ball Check Valve Features and Buying Guide

| Feature |

Description |

Material |

Size Range |

Pressure Rating |

| Automated Operation |

Allows for remote control via sensors. |

Stainless Steel |

1" - 6" |

150 PSI |

| Spring Loaded |

Ensures tighter sealing during low flow conditions. |

PVC |

3/4" - 4" |

100 PSI |

| Dual-Purpose |

Acts as both a check and a ball valve. |

Brass |

1" - 3" |

200 PSI |

| UV Resistant |

Suitable for outdoor applications. |

Polypropylene |

1" - 4" |

80 PSI |

| Low Maintenance Design |

Minimizes the need for regular upkeep. |

Acetal |

1" - 2" |

150 PSI |

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.