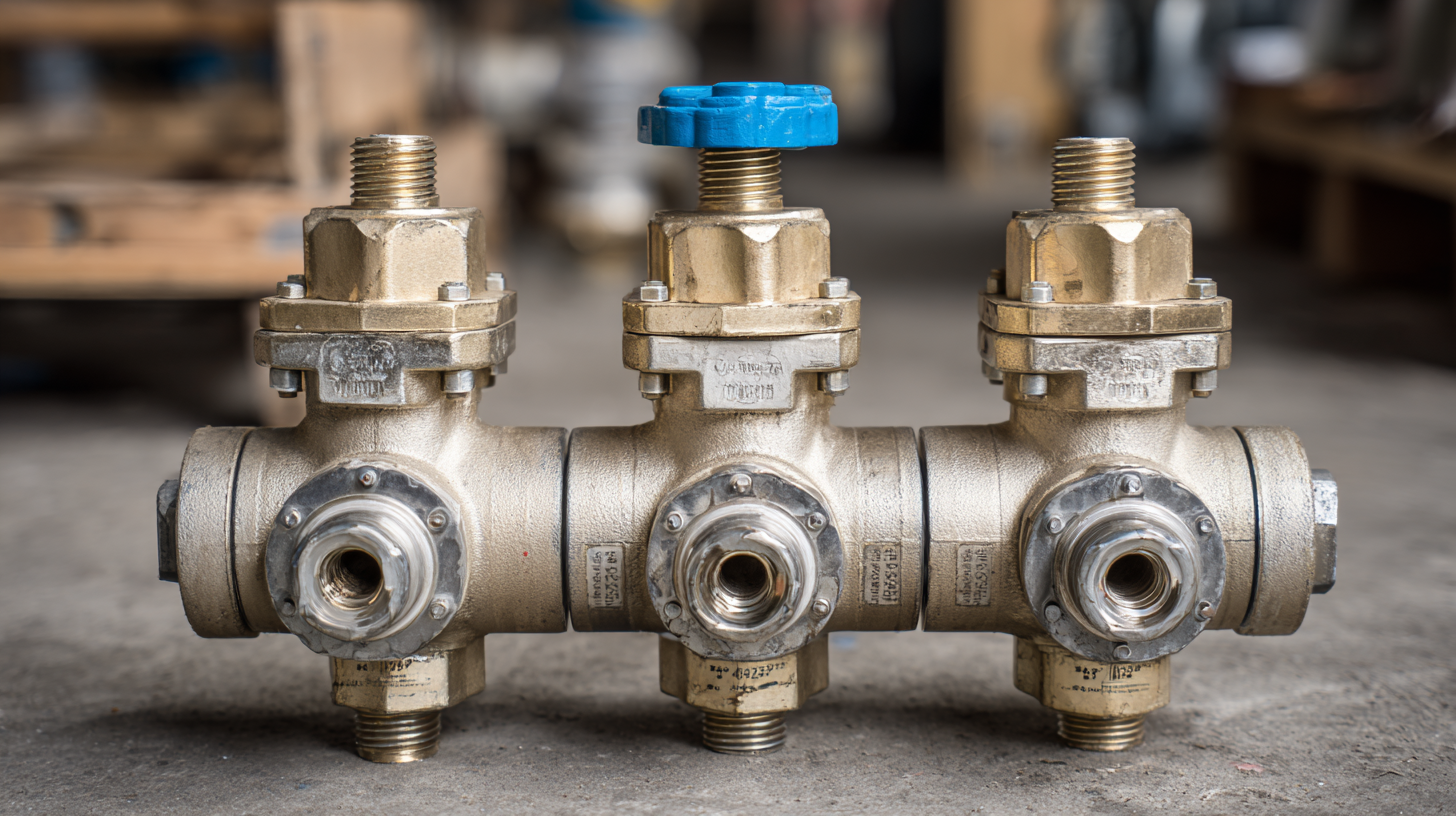

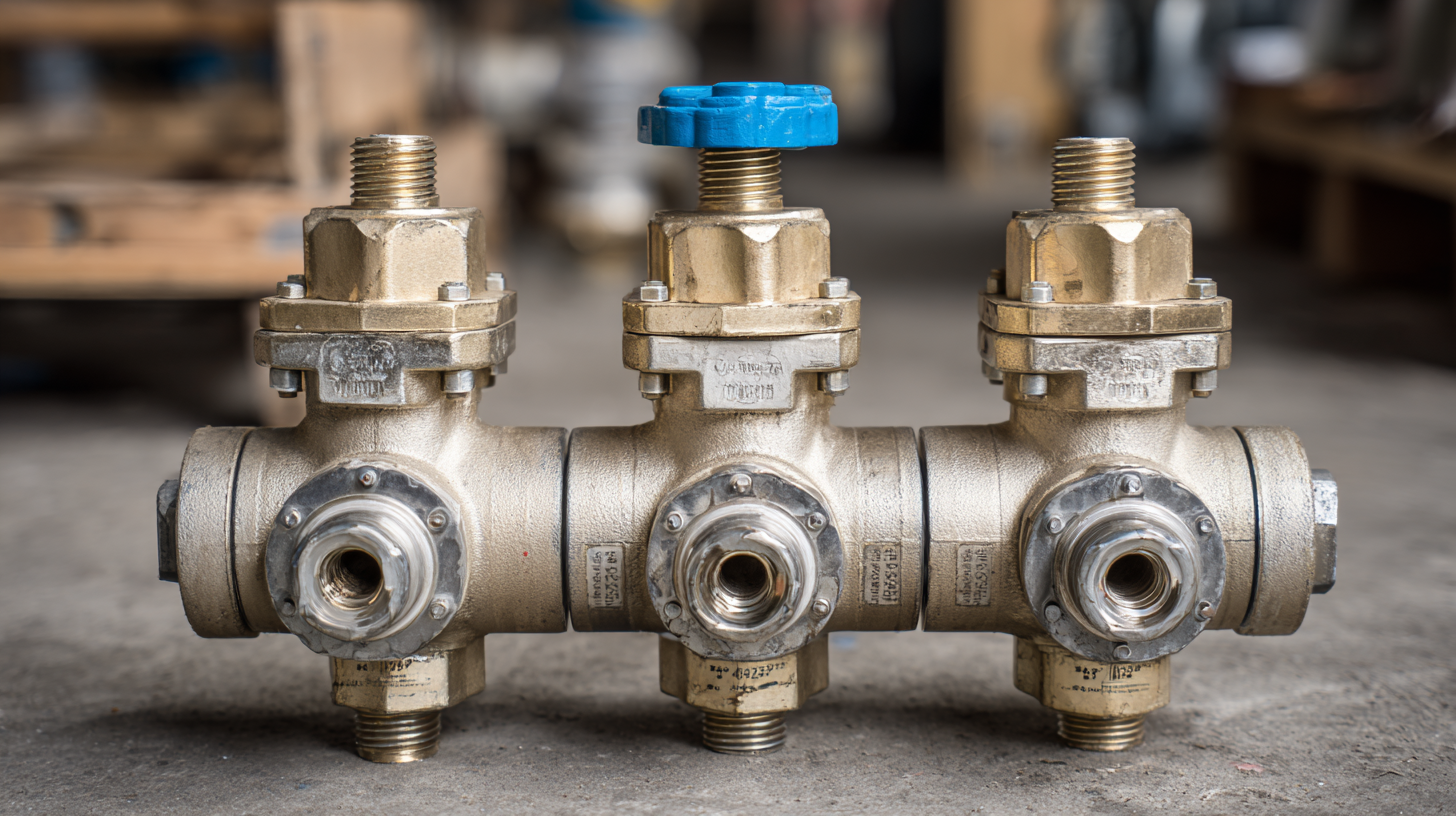

10 Best Three Way Valves for Your Business Needs

In the world of industrial processes and fluid control, the three way valve stands out as a crucial component that ensures efficient management of fluid flow. These valves are designed to control the direction of flow in piping systems, offering versatility and flexibility that can be tailored to various business needs. Whether you're in the manufacturing, chemical, or agricultural sectors, selecting the right three way valve can greatly impact your operational efficiency and productivity. This blog will explore the 10 best three way valves available in the market, delving into their unique features, applications, and the benefits they bring to different industries. Understanding the types and functionalities of these valves is essential for making informed decisions that enhance your business operations.

Understanding Three Way Valves: Types and Applications

Three-way valves are essential components in fluid control systems across various industries, allowing for effective flow regulation and directional control. Understanding the types of three-way valves and their applications can significantly enhance operational efficiency in business processes. For instance, the cryogenic valve market in the U.S. is projected to grow from USD 215.4 million in 2024 to USD 394.5 million by 2034, highlighting the increasing demand for specialized valve technologies in sectors such as cryogenics and biomedical applications.

Three-way valves are essential components in fluid control systems across various industries, allowing for effective flow regulation and directional control. Understanding the types of three-way valves and their applications can significantly enhance operational efficiency in business processes. For instance, the cryogenic valve market in the U.S. is projected to grow from USD 215.4 million in 2024 to USD 394.5 million by 2034, highlighting the increasing demand for specialized valve technologies in sectors such as cryogenics and biomedical applications.

In high-pressure environments, several critical factors must be considered when selecting valves, such as maximum operating pressure, valve materials, connection types, and leakage tolerance. These elements are crucial for ensuring reliability and performance. New developments in microfluidic technologies further emphasize the evolution of valve design, with advancements like thermally-actuated microfluidic membrane valves enabling precise control in point-of-care applications. As the industrial valve market continues to expand, particularly with projected growth through 2034, businesses must adapt to these changes and explore innovative valve solutions to remain competitive.

Key Features to Look for in a Three Way Valve for Your Business

When selecting the ideal three-way valve for your business, it’s crucial to focus on several key features that can significantly impact your operations. One of the vital characteristics is the valve’s material, which can affect durability and resistance to corrosion. A report by the Global Market Insights suggests that the demand for stainless steel valves is projected to grow by over 5% annually, driven by their longevity in harsh environments.

Another essential feature to consider is the valve’s flow configuration. Depending on your application—whether it’s for mixing, diverting, or throttling—different configurations such as L-port and T-port valves serve distinct purposes. According to a recent study by Market Research Future, the versatility offered by three-way valves can lead to up to a 20% increase in system efficiency.

Tip: Always check the valve’s pressure rating and temperature limits to ensure compatibility with your system's operating conditions.

Tip: Additionally, investing in automated control options for your three-way valves can enhance operational efficiency and reduce labor costs, making them a smart addition to your business setup.

Comparing the Top Brands: A Review of the Best Three Way Valves

In the realm of industrial applications, three-way valves play a critical role in controlling the flow of fluids and gases. A recent industry report indicates that the global three-way valves market is projected to grow at a CAGR of 4.8% from 2023 to 2030, driven by the increasing demand from sectors like oil and gas, water and wastewater treatment, and HVAC systems. Among the top brands dominating this market, companies like Val-Matic, Swagelok, and Parker stand out for their innovative designs and reliability.

When choosing the best three-way valve for your business needs, it is essential to consider factors such as material compatibility, pressure ratings, and the type of actuation required. For instance, valves constructed from stainless steel provide superior corrosion resistance, making them ideal for harsh environments.

**Tips:** Always assess the specific fluid properties in your application, as this can significantly impact valve performance. Additionally, consider the ease of maintenance and availability of spare parts when selecting a brand, as this can enhance the longevity of your valve system. Finally, consulting with a trusted supplier can offer insights tailored to your operational needs, ensuring you make an informed decision.

Comparison of Three Way Valve Performance Metrics

This chart presents a comparison of various performance metrics for different three way valves commonly used in industrial applications. The metrics include Flow Rate (GPM), Pressure Drop (PSI), and Temperature Range (°F).

Installation Tips: How to Properly Set Up Your Three Way Valve

When it comes to installing a three-way valve, proper setup is crucial to ensuring optimal performance and longevity. Begin by selecting the right location for the valve. It should be positioned where it can easily redirect flow without causing turbulence in the system. Make sure to check that surrounding components, such as pipes and fittings, are aligned to minimize stress on the valve body during operation.

Before installation, it's essential to clean the valve and connecting pipes thoroughly to prevent debris from clogs and leaks. Utilize Teflon tape on threaded connections for a more secure seal, but be careful not to over-tighten as this can damage the threads. Once in place, ensure that the actuator or manual handle is oriented correctly to facilitate easy operation.

Finally, after installation, conduct a pressure test to check for leaks and confirm that the valve operates smoothly in all positions, establishing both reliability and efficiency in your system.

Maintenance Best Practices for Longevity of Three Way Valves

Maintaining the longevity of three-way valves is essential for optimal performance in various industrial applications. According to a recent industry report by Frost & Sullivan, neglecting regular maintenance can lead to a reduction in valve efficiency by up to 30%, resulting in costly downtime and increased operational expenses. To prevent this, it is crucial to implement routine inspections and maintenance practices that focus on both valve functionality and sealing integrity.

One effective tip is to routinely clean the valve to remove debris and buildup that can hinder performance. Utilize a soft brush and approved cleaning agents to avoid damaging sensitive components. Furthermore, monitoring the operating pressure and temperature can preemptively identify issues before they escalate. Keeping the valve's exterior free from corrosion and leaks also contributes to its overall lifespan.

Lastly, consider establishing a preventative maintenance schedule. Regular maintenance checks should include disassembling the valve unit for thorough inspections of internal parts for wear and tear. According to ANSI/ISA standards, such diligence can significantly enhance the operational stability of three-way valves and assure their reliability in critical processes.

10 Best Three Way Valves for Your Business Needs - Maintenance Best Practices for Longevity of Three Way Valves

| Valve Type |

Material |

Size (Inches) |

Pressure Rating (PSI) |

Temperature Range (°F) |

Maintenance Frequency |

| Ball Valve |

Stainless Steel |

2 |

150 |

-20 to 350 |

Annually |

| Globe Valve |

Brass |

1.5 |

200 |

-10 to 300 |

Semi-Annually |

| Butterfly Valve |

PVC |

3 |

75 |

-20 to 140 |

Quarterly |

| Check Valve |

Cast Iron |

4 |

250 |

-10 to 400 |

Annually |

| Gate Valve |

Steel |

2.5 |

300 |

-20 to 450 |

Semi-Annually |

| Pressure Relief Valve |

Bronze |

1 |

150 |

-20 to 300 |

Annually |

| Dewatering Valve |

Aluminum |

3.5 |

100 |

-10 to 200 |

Quarterly |

| Diving Valve |

PVC |

2 |

80 |

0 to 120 |

Monthly |

| Float Valve |

Nylon |

1.5 |

60 |

-5 to 130 |

Bi-Annually |

| Isolation Valve |

Ductile Iron |

3 |

150 |

-20 to 250 |

Annually |

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

Three-way valves are essential components in fluid control systems across various industries, allowing for effective flow regulation and directional control. Understanding the types of three-way valves and their applications can significantly enhance operational efficiency in business processes. For instance, the

Three-way valves are essential components in fluid control systems across various industries, allowing for effective flow regulation and directional control. Understanding the types of three-way valves and their applications can significantly enhance operational efficiency in business processes. For instance, the