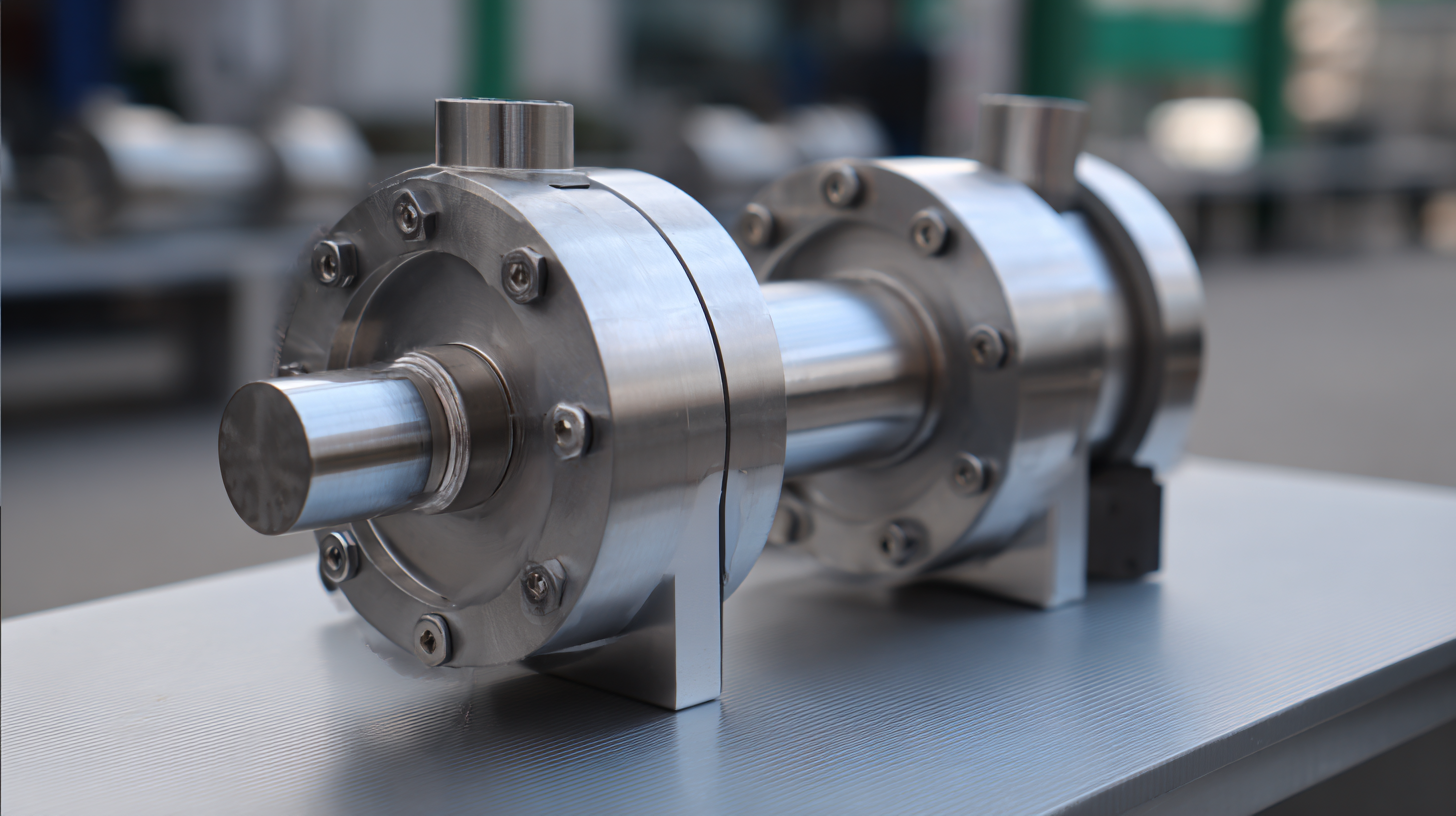

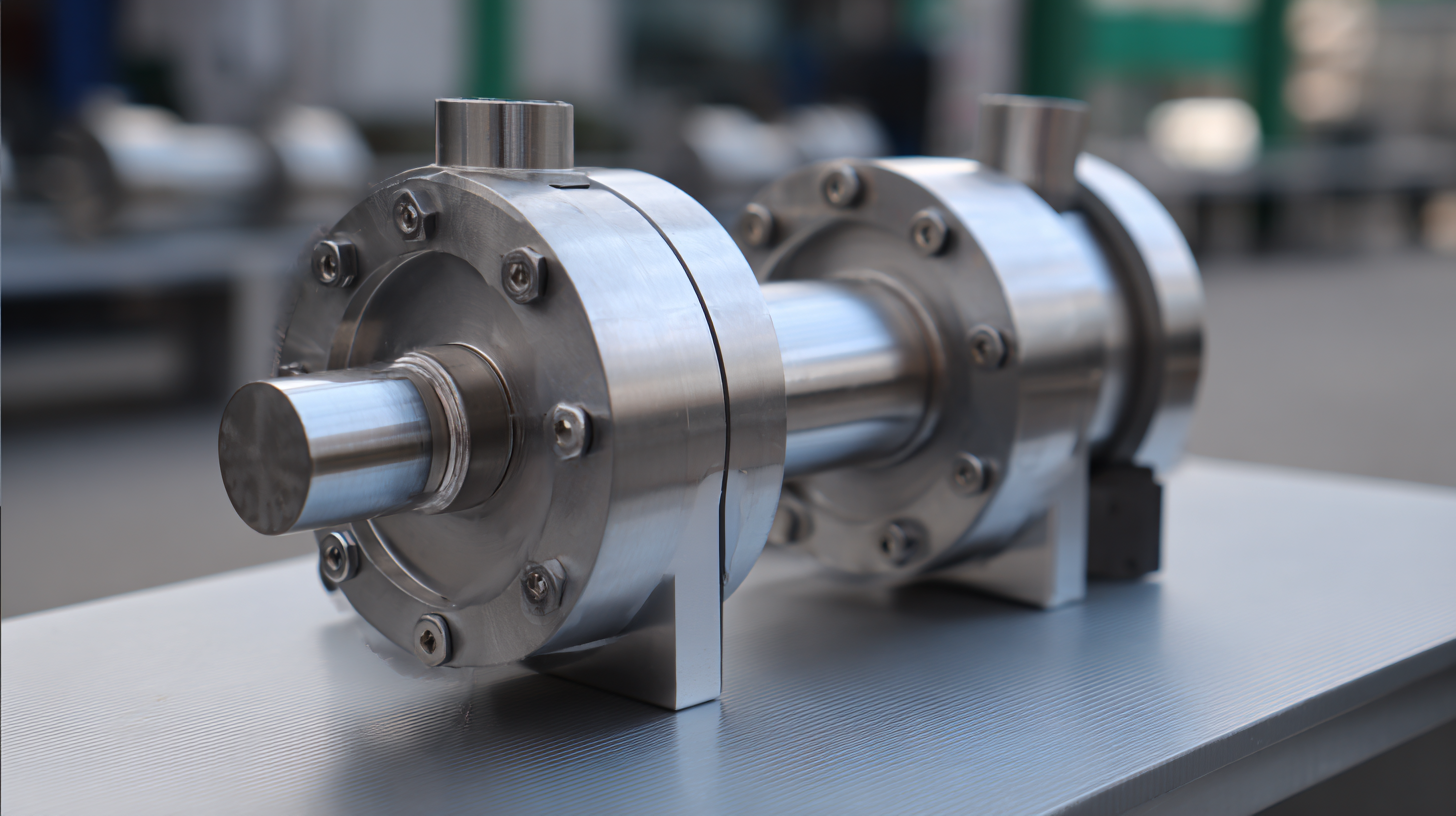

Unleashing Quality with Best Wafer Check Valve by China's Leading Manufacturer for Global Markets

In recent years, the global demand for high-quality wafer check valves has surged, driven by industries ranging from oil and gas to water treatment. According to a report by Global Market Insights, the market for check valves is projected to surpass $5 billion by 2026, with a significant portion attributed to wafer check valves due to their compact design and efficiency. China's leading manufacturers are at the forefront of this growth, continually innovating to enhance product quality while meeting rigorous international standards. With a focus on durability, reliability, and performance, these companies play a pivotal role in supplying global markets and ensuring optimal flow control solutions. This guide aims to explore the benefits of investing in high-quality wafer check valves and highlights the key features that set the best manufacturers apart in today's competitive landscape.

Advantages of Comprehensive After-Sales Service in Valve Solutions

In today’s competitive market, the advantages of comprehensive after-sales service in valve solutions cannot be overstated. For manufacturers and customers alike, a robust after-sales service ensures that any challenges encountered post-purchase are addressed promptly, thus maintaining the integrity and performance of the valve systems. With the best wafer check valves produced by China’s leading manufacturer, clients benefit from an enhanced service structure that includes installation assistance, regular maintenance checks, and immediate troubleshooting support. This commitment to service not only elevates customer satisfaction but also extends the lifespan of the valves, saving companies time and money in the long run.

Moreover, an effective after-sales service fosters long-term relationships between manufacturers and clients. With dedicated support teams ready to assist, users are more likely to trust the brand and consider it for future purchases. This open line of communication allows manufacturers to receive valuable feedback, which can drive innovation and product improvements. The combination of high-quality wafer check valves and superior after-sales service creates a powerful offering that sets leading manufacturers apart in global markets, making them the go-to choice for reliable and efficient valve solutions.

Unleashing Quality with Best Wafer Check Valve by China's Leading Manufacturer for Global Markets - Advantages of Comprehensive After-Sales Service in Valve Solutions

| Feature |

Description |

Benefit |

After-Sales Service |

| Durability |

Manufactured with robust materials for long life. |

Reduces replacement costs and downtime. |

Availability of replacement parts within 48 hours. |

| Design |

Compact and lightweight design for easy installation. |

Saves space and reduces installation labor. |

Free installation consultation and support. |

| Flow Efficiency |

Optimized flow path to minimize pressure drop. |

Increases system efficiency and reduces energy costs. |

Regular performance evaluations included. |

| Versatility |

Compatible with various fluids and gases. |

Can be used in multiple applications. |

Tailored solutions for specific applications. |

Understanding Maintenance Costs for Wafer Check Valves

The maintenance costs associated with wafer check valves are critical for manufacturers and facility managers looking to optimize operational efficiency and minimize downtime. According to a recent report by MarketsandMarkets, the valve market is projected to grow from $89.0 billion in 2020 to $116.5 billion by 2025, reflecting an increasing need for reliable and cost-effective solutions. Despite their advantages in terms of space-saving design and lightweight structure, wafer check valves require regular inspections and maintenance due to issues such as wear and seat sealing degradation. In an analysis by Frost & Sullivan, it was found that the total cost of valve ownership can be reduced by up to 30% through effective predictive maintenance strategies.

Moreover, investing in high-quality wafer check valves can lead to long-term savings. A study by ResearchAndMarkets indicates that quality components enhance system reliability and reduce frequency and severity of failures. The upfront cost may be higher, but premium wafer check valves often showcase a lifespan increase of 15-20%, significantly lowering replacement and repair costs. This shift not only contributes to better performance but also aligns with sustainability goals by minimizing the environmental impact through reduced waste and resource consumption.

How China's Leading Manufacturer Enhances Global Market Reach

In today’s competitive landscape, China's leading manufacturers are strategically enhancing their global market reach, particularly in sectors like robotics and advanced manufacturing. With the global robotics market predicted to exceed $400 billion by 2029, driven by technological advancements and supportive policies, Chinese companies are poised to play a pivotal role. This wave of growth underscores the importance of maintaining quality, as evidenced by innovations in products like wafer check valves that meet international standards.

To successfully tap into global markets, companies should focus on building strong partnerships and leveraging local insights. For instance, understanding regional demands can guide product development and marketing strategies. Additionally, investing in cutting-edge technology and manufacturing processes not only boosts product quality but also establishes a brand’s reputation internationally.

Here are some tips for manufacturers looking to enter or expand in global markets:

- **Network Extensively**: Attend international trade shows and business forums to connect with potential partners and customers.

- **Adapt to Local Markets**: Tailor products and services to meet the specific needs and preferences of different regions.

- **Emphasize Quality Assurance**: Implement strict quality control measures to ensure that products consistently meet high standards required in various markets.

Market Share of Wafer Check Valves by Region

This chart illustrates the market share of wafer check valves produced by China's leading manufacturer in various global regions, highlighting their enhanced reach in recent years.

Quality Assurance Strategies in Manufacturing Wafer Check Valves

In the competitive landscape of valve manufacturing, quality assurance is paramount, especially for wafer check valves, which are crucial components in various industrial applications. Leading manufacturers in China are adopting advanced quality assurance strategies that include rigorous testing protocols, material verification processes, and innovative manufacturing technologies. According to a recent report by MarketsandMarkets, the global valve market is projected to reach $88.7 billion by 2025, emphasizing the need for superior quality control measures to meet growing demands.

To ensure the highest standards, manufacturers implement six sigma methodologies to minimize defects and optimize production efficiency. By employing statistical process control, they can monitor production in real-time and address potential issues before they escalate. Additionally, the incorporation of automated testing systems has enhanced the reliability of wafer check valves, allowing for precise evaluation of performance attributes such as pressure retention and flow characteristics.

**Tips:** When selecting wafer check valves, always inquire about the manufacturer's quality assurance certifications. Look for ISO 9001 certification, which indicates a strong commitment to quality management principles. Additionally, consider suppliers that provide comprehensive testing results, ensuring that the valves meet international standards for safety and performance. Regular maintenance and inspections can also prolong the lifespan of these critical components.

Innovative Technologies to Reduce Maintenance Frequency and Costs

In today's fast-paced industrial landscape, reducing maintenance frequency and costs is paramount, especially for critical components like wafer check valves. China’s leading manufacturer is setting a new standard with innovative technologies designed to enhance durability and performance while minimizing downtime. By leveraging advancements in design and materials, these valves not only ensure optimal flow control but also significantly lower maintenance needs.

In today's fast-paced industrial landscape, reducing maintenance frequency and costs is paramount, especially for critical components like wafer check valves. China’s leading manufacturer is setting a new standard with innovative technologies designed to enhance durability and performance while minimizing downtime. By leveraging advancements in design and materials, these valves not only ensure optimal flow control but also significantly lower maintenance needs.

Tip: Implement regular monitoring systems to track valve performance and identify potential issues before they escalate. This proactive approach can substantially cut down on unexpected maintenance costs and keep operations running smoothly.

Moreover, incorporating smart technologies can further enhance maintenance efficiency. For instance, integrating IoT solutions provides real-time data on valve condition and performance, enabling predictive maintenance strategies that align with the latest industry practices.

Tip: Train your maintenance staff on using these smart technologies effectively to maximize the benefits and ensure your systems are always at peak performance.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

In today's fast-paced industrial landscape, reducing maintenance frequency and costs is paramount, especially for critical components like wafer check valves. China’s leading manufacturer is setting a new standard with innovative technologies designed to enhance

In today's fast-paced industrial landscape, reducing maintenance frequency and costs is paramount, especially for critical components like wafer check valves. China’s leading manufacturer is setting a new standard with innovative technologies designed to enhance