Essential Checklist for Choosing the Perfect Three Way Ball Valve for Your Applications

Choosing the right three way ball valve for your applications can significantly impact the efficiency and effectiveness of your fluid control systems. This essential checklist aims to guide you through the critical considerations essential for selecting the perfect three way ball valve. From understanding the various types available to evaluating materials, pressure ratings, and connection types, each factor plays a vital role in ensuring optimal performance. Whether you are dealing with water, oil, gas, or other industrial fluids, making an informed choice is crucial for reliability and functionality. With this in mind, we've outlined key elements to assess during your selection process, empowering you to make the best decision tailored to your specific needs and operational requirements.

Understanding Three Way Ball Valve Types and Their Alternatives

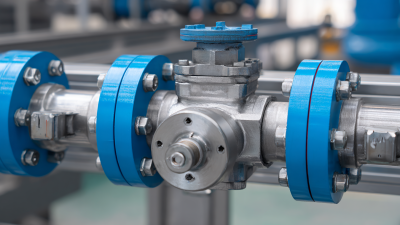

When it comes to selecting a three-way ball valve, understanding the types available as well as their alternatives is crucial for ensuring optimal performance in your application. Three-way ball valves typically fall into three categories: L-port, T-port, and multi-port configurations. L-port valves allow for straightforward fluid flow between two outlets, making them ideal for diverting flows. T-port valves, on the other hand, enable mixing or splitting flow, offering greater flexibility for applications that require precise control over fluid distribution. Knowing the specific functional capabilities of each type is essential for choosing the right valve for your needs.

In addition to traditional three-way ball valves, there are alternative options worth considering. For instance, rotary actuated valves can serve similar purposes in certain applications, providing versatility in flow regulation and control. Diaphragm valves may also serve as an alternative, especially in processes where hygienic conditions are a priority. Evaluating these alternatives in the context of your operational requirements can further enhance system efficiency and may lead to cost savings over time. The right choice will not only depend on the valve type but also on how it fits within the overall system architecture and process needs.

Three Way Ball Valve Type Analysis

Key Factors to Consider When Selecting Alternative Valves

When selecting alternative valves, several critical factors must be considered to ensure optimal performance in various applications. According to a report by MarketsandMarkets, the global valve market is projected to reach $86.3 billion by 2025, with increasing demand for efficient flow control solutions. The type of valve, its material, and the operational environment significantly influence performance and longevity. For instance, ball valves, particularly three-way variants, are favored in industries like oil and gas due to their superior sealing capabilities and flow regulation.

Another vital aspect is the valve's compatibility with process fluids. An analysis from the International Society of Automation highlights that nearly 30% of valve failures are due to corrosion or wear from incompatible materials. Therefore, selecting the right material—be it stainless steel, brass, or PVC—based on the chemical properties of the fluids involved is crucial. Furthermore, dimensions and pressure ratings must align with the specific requirements of the application to avoid operational risks. By thoroughly evaluating these factors, industries can enhance efficiency and reduce maintenance costs, ultimately contributing to more sustainable operations.

Essential Checklist for Choosing the Perfect Three Way Ball Valve for Your Applications - Key Factors to Consider When Selecting Alternative Valves

| Feature |

Description |

Importance Level |

Common Materials |

| Pressure Rating |

Maximum pressure the valve can handle |

High |

Stainless Steel, Brass |

| Temperature Range |

Operating temperature limits for the valve |

High |

PTFE, PVC |

| Connection Type |

Method of connecting the valve to pipes |

Medium |

Flanged, Threaded |

| Body Style |

Design configuration of the valve body |

Medium |

L-Port, T-Port |

| Flow Capacity |

Volume of fluid that can pass through |

High |

Varies by design |

| Actuation Type |

Method of valve operation (manual or automated) |

Medium |

Electric, Pneumatic |

| Seal Type |

Material used for sealing between valve parts |

High |

Nitrile, EPDM |

Comparative Analysis: Three Way Ball Valves vs. Their Alternatives

When selecting a valve for a specific application, the decision between a

three-way ball valve and its alternatives such

as gate, globe, or butterfly valves is critical. According to a recent

report by MarketsandMarkets, the global valve market is projected to reach

$98.63 billion by 2026, with three-way ball valves

expected to capture a significant share due to their efficient flow control and versatility.

Unlike traditional valves that offer limited directional control, three-way ball valves

provide the ability to divert or mix fluids, making them indispensable in industries such

as chemical processing and water treatment.

In a comparative analysis of flow characteristics, a study published in the

Journal of Fluid Mechanics indicates that

three-way ball valves can maintain higher flow rates and lower pressure drops than

butterfly or globe valves, making them superior in applications requiring

high volume transport. Moreover, their quarter-turn

operation allows for faster cycling and less wear over time, enhancing their durability.

As industrial demands evolve toward more efficient and reliable solutions,

three-way ball valves stand out as a robust choice over

alternatives, aligning with the growing emphasis on operational efficiency and

maintenance reduction in modern infrastructure.

Advantages and Disadvantages of Using Alternative Valve Types

When it comes to selecting the right valve for your applications, it’s essential to weigh the advantages and disadvantages of alternative valve types.

For instance, while globe valves are often praised for their superior throttling capability, they may not perform as well in on-off services due to higher pressure drops. On the other hand, butterfly valves are lightweight and can handle large volumes of flow, but they might lack the tight shut-off found in ball valves. Understanding these trade-offs will help you make an informed decision.

Tip: Always consider the specific needs of your application, such as pressure requirements and flow control precision. Evaluating these factors will guide you in determining whether a three-way ball valve or an alternative type is more suitable.

Another alternative worth considering is the check valve, which is designed to prevent backflow.

While they are effective for this purpose, one must be cautious about the potential for water hammer and the necessity of additional maintenance in specific scenarios. Each valve type has its unique characteristics that can greatly affect system performance.

Tip: Regularly review your valve assembly and maintenance protocols to ensure that the selected valve type continues to meet operational demands effectively.

Applications Best Suited for Alternative Valves Over Three Way Ball Valves

When selecting a valve for specific applications, understanding the advantages and limitations of three-way ball valves is crucial. While these valves excel in redirecting flow within a piping system, certain scenarios call for alternative valve types to achieve optimal performance. For instance, in systems requiring precise flow control, such as in chemical processing or laboratory setups, globe valves or control valves may better serve the purpose, providing finer adjustments and less turbulence.

Furthermore, in applications dealing with high viscosity fluids or slurries, butterfly valves can be more efficient. Their design allows for less pressure drop and smoother flow, which is particularly beneficial in handling thicker materials. Similarly, in scenarios that demand quick shutoff capabilities, gate valves might be preferable. They provide a tighter seal and are more effective in on/off applications without the need for modulating flow, making them suitable for different industrial processes where reliability is key. By carefully assessing the specific needs of an application, one can make an informed choice that ensures efficiency and effectiveness in fluid management.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.