How to Choose the Right High Performance Butterfly Valve for Your Industry

In various industries, the selection of the appropriate high performance butterfly valves is critical for ensuring efficiency and reliability in fluid control systems. According to a report by Global Market Insights, the demand for butterfly valves is expected to exceed USD 10 billion by 2025, driven by their benefits such as low torque requirements, lightweight construction, and versatility in handling various media. Industries ranging from oil and gas to water treatment increasingly rely on high performance butterfly valves to optimize performance while minimizing operational costs. Selecting the right valve not only affects the operational efficacy but also impacts safety and compliance with regulatory standards. This guide aims to provide essential insights into the selection process, helping industry professionals make informed decisions when choosing high performance butterfly valves suited to their specific needs and applications.

Understanding Butterfly Valve Types and Their Applications in Various Industries

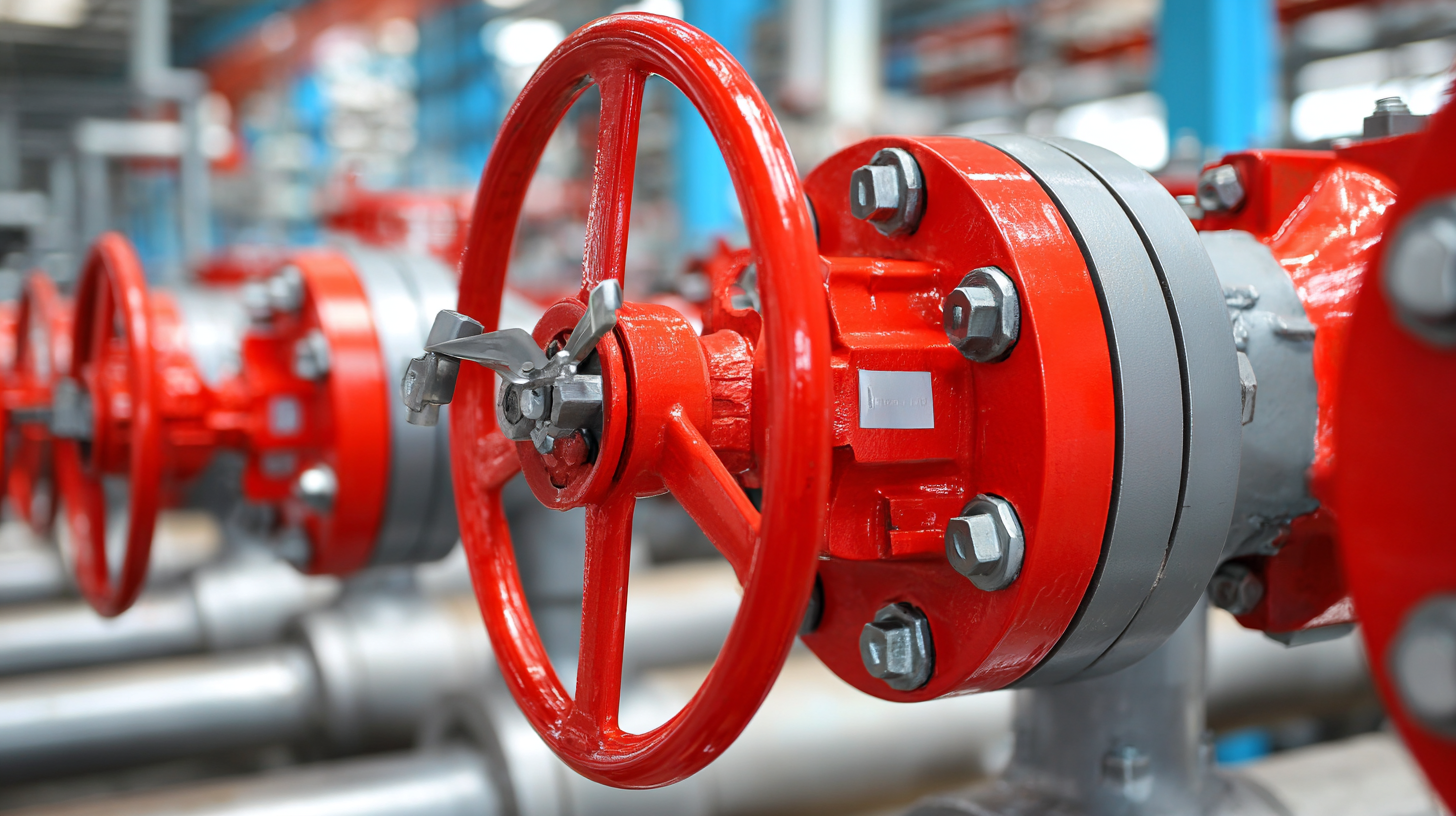

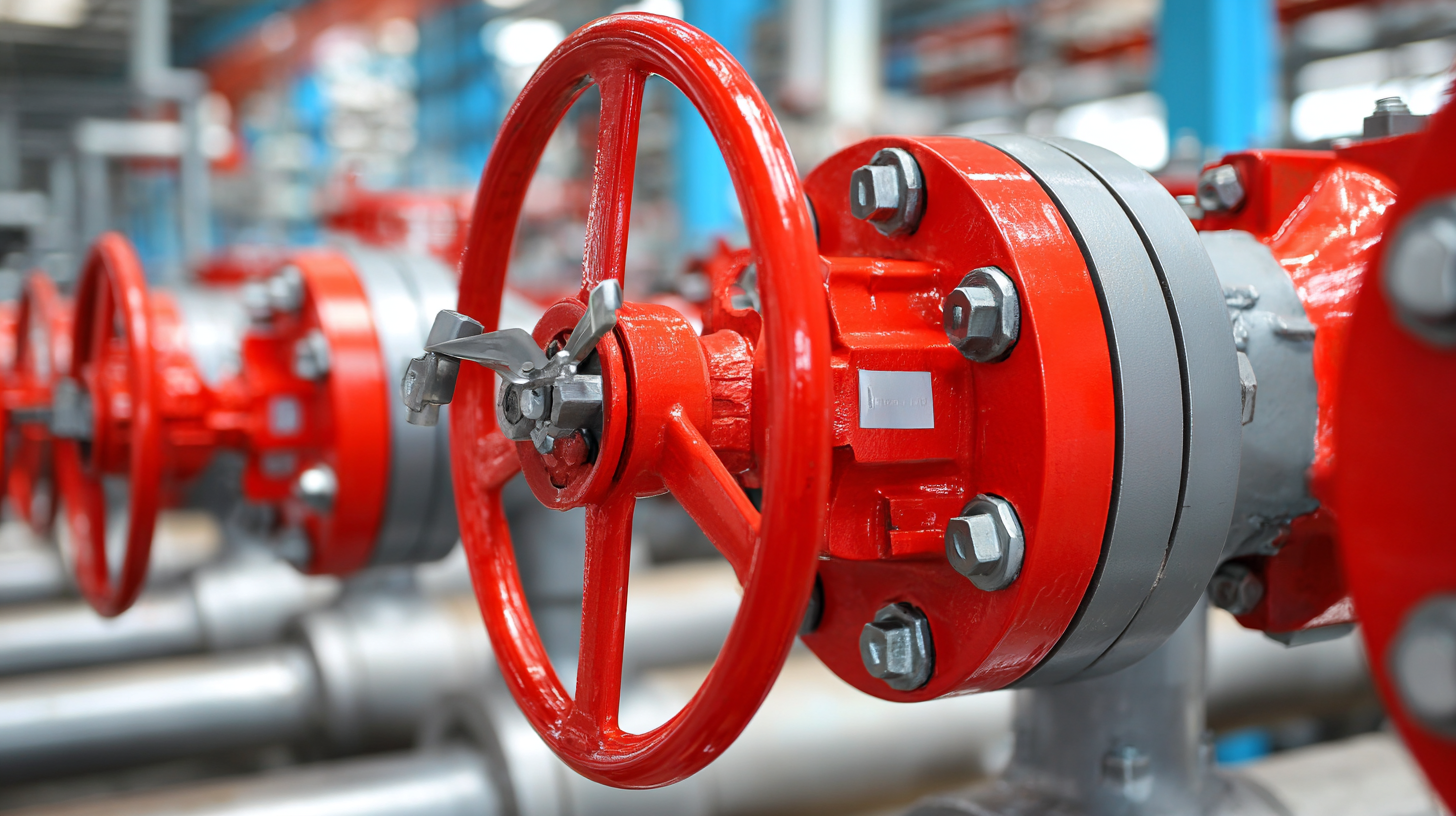

When selecting a high-performance butterfly valve for your industry, it is essential to understand the different types available and their specific applications. Butterfly valves are commonly categorized into three types: centric, eccentric, and double eccentric. Centric butterflies are typically used in lower pressure applications due to their simple design, making them cost-effective for basic flow control. Eccentric and double eccentric valves, on the other hand, are designed for higher pressures and can better handle the flow with minimal turbulence, making them suitable for industries such as oil and gas, water treatment, and chemical processing.

The application of butterfly valves varies widely across different sectors. In HVAC systems, for example, centric butterfly valves are ideal for regulating flow with low energy loss. Meanwhile, in the food and beverage industry, sanitary butterfly valves are crucial for maintaining hygiene and preventing contamination. Understanding these distinctions not only helps in selecting the right valve but also ensures compliance with industry standards and operational efficiency. Proper assessment of your specific needs and the characteristics of your chosen butterfly valve type can lead to optimized performance and longevity in various applications.

Key Performance Metrics to Evaluate When Selecting a High Performance Butterfly Valve

When selecting a high-performance butterfly valve for your industry, it is crucial to evaluate several key performance metrics that directly impact efficiency and reliability. According to a report from the International Journal of Engineering Research and Applications, factors such as flow coefficient (Cv), pressure drop, and temperature range must be carefully considered. For instance, a valve that boasts a high Cv value can facilitate greater flow rates while maintaining a lower pressure drop, which is essential in high-demand industrial applications. Industry benchmarks suggest that valves with a Cv above 200 are often preferred for heavy-duty operations, ensuring optimal performance and reduced energy consumption.

Another critical metric is the valve’s seat leakage rating, which determines how effectively the valve can prevent media leakage under specified conditions. The American Petroleum Institute outlines that a leakage class of 0 may be necessary for hydronic systems, whereas a class above 4 may suffice in less critical applications. Furthermore, assessing the materials of construction is vital; materials that can withstand high temperatures (above 400°F) and corrosive environments significantly enhance a valve's durability, as highlighted in the latest ASME B16.34 standards. Overall, focusing on these performance metrics can lead to a more informed decision, ensuring the selection of a butterfly valve that meets both operational requirements and industry standards.

How to Choose the Right High Performance Butterfly Valve for Your Industry - Key Performance Metrics to Evaluate When Selecting a High Performance Butterfly Valve

| Metric |

Description |

Importance |

Recommended Value |

| Valve Size |

Nominal diameter of the valve |

Critical for ensuring proper flow rates |

Match with pipe size |

| Material |

Material used for valve construction |

Affects durability and compatibility |

Corrosion-resistant materials |

| Pressure Rating |

Maximum pressure the valve can withstand |

Ensures safe operation under pressure |

Class 150 to Class 600 |

| Temperature Range |

Operating temperature limits |

Prevents thermal damage |

-20°C to 150°C |

| Flow Coefficient (Cv) |

Measure of valve efficiency |

Higher Cv values indicate better flow |

Depends on application |

| Actuation Type |

Method used to open/close valve |

Impacts automation and control |

Electric or pneumatic preferred |

| End Connection Type |

Method used to connect to piping system |

Ensures proper fitting and leakage prevention |

Flanged or wafer style |

Material Considerations: Selecting the Right Butterfly Valve for Chemical Resistance

When selecting a high-performance butterfly valve for applications involving chemical resistance, material considerations play a crucial role. The choice of material directly influences the valve's durability, compatibility with various chemicals, and overall performance in extreme conditions. Common materials for butterfly valves include stainless steel, polymer, and various alloys. While stainless steel offers excellent strength and corrosion resistance, certain chemicals may require specific polymers or exotic alloys to prevent degradation.

Furthermore, understanding the chemical properties of the fluid being handled is essential. Factors such as temperature, pressure, and pH levels can significantly affect the valve’s material performance. For example, corrosive substances like acids and alkalis may necessitate valves made from food-grade plastic or specialty metals designed to withstand harsh environments. It’s important to consult the manufacturer's chemical compatibility charts to ensure the selected material can withstand potential chemical interactions and pressures, thereby enhancing the longevity and reliability of the butterfly valve in your industrial processes.

Sizing and Dimensions: Ensuring Proper Fit for Optimal Flow Control

When selecting a high-performance butterfly valve for industrial applications, the importance of proper sizing and dimensions cannot be overstated. An accurately sized valve ensures that the flow control system operates at its peak efficiency, minimizing energy loss and maximizing throughput. Considerations such as the nominal diameter, pressure drop, and the specific fluid characteristics are crucial in determining the correct valve size. This ensures that the valve can accommodate the flow rate required by the system, avoiding issues like cavitation or excessive turbulence.

In addition to size, the dimensions of the valve body and actuator play a significant role in its installation and compatibility with existing piping systems. A well-suited butterfly valve should align correctly with the flanges and allow for adequate space for operation and maintenance. Customizing dimensions to fit the unique needs of your setup can prevent costly modifications down the line. Therefore, a detailed analysis of both the flow requirements and the spatial constraints of your piping network will lead to more effective flow control and enhanced system performance.

Cost-Benefit Analysis of High Performance Butterfly Valves in Industrial Operations

The selection of high-performance butterfly valves is crucial for enhancing operational efficiency in various industrial sectors. A thorough cost-benefit analysis can help businesses determine the most advantageous choice for their specific needs. While the initial cost of these valves may be higher than traditional options, their long lifespan and reduced maintenance requirements often translate into significant savings over time.

When considering high-performance butterfly valves, keep the following tips in mind: First, evaluate the fluid characteristics—temperature, pressure, and chemical composition—to ensure compatibility with the valve material. Second, analyze the flow requirements; the right valve specification can optimize flow control and minimize energy consumption. Lastly, consider the manufacturer’s reputation and warranty offers. A reliable supplier not only guarantees product quality but also provides essential support during installation and maintenance.

Investing in high-performance butterfly valves can yield exceptional returns in terms of productivity and reduced downtime. By carefully analyzing costs and benefits, industries can make informed decisions that align with their operational goals and financial realities.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.