The Ultimate Guide to Choosing High Pressure Ball Valves for Efficient Industrial Applications

When it comes to optimizing industrial applications, selecting the right components is crucial for achieving operational efficiency and safety.

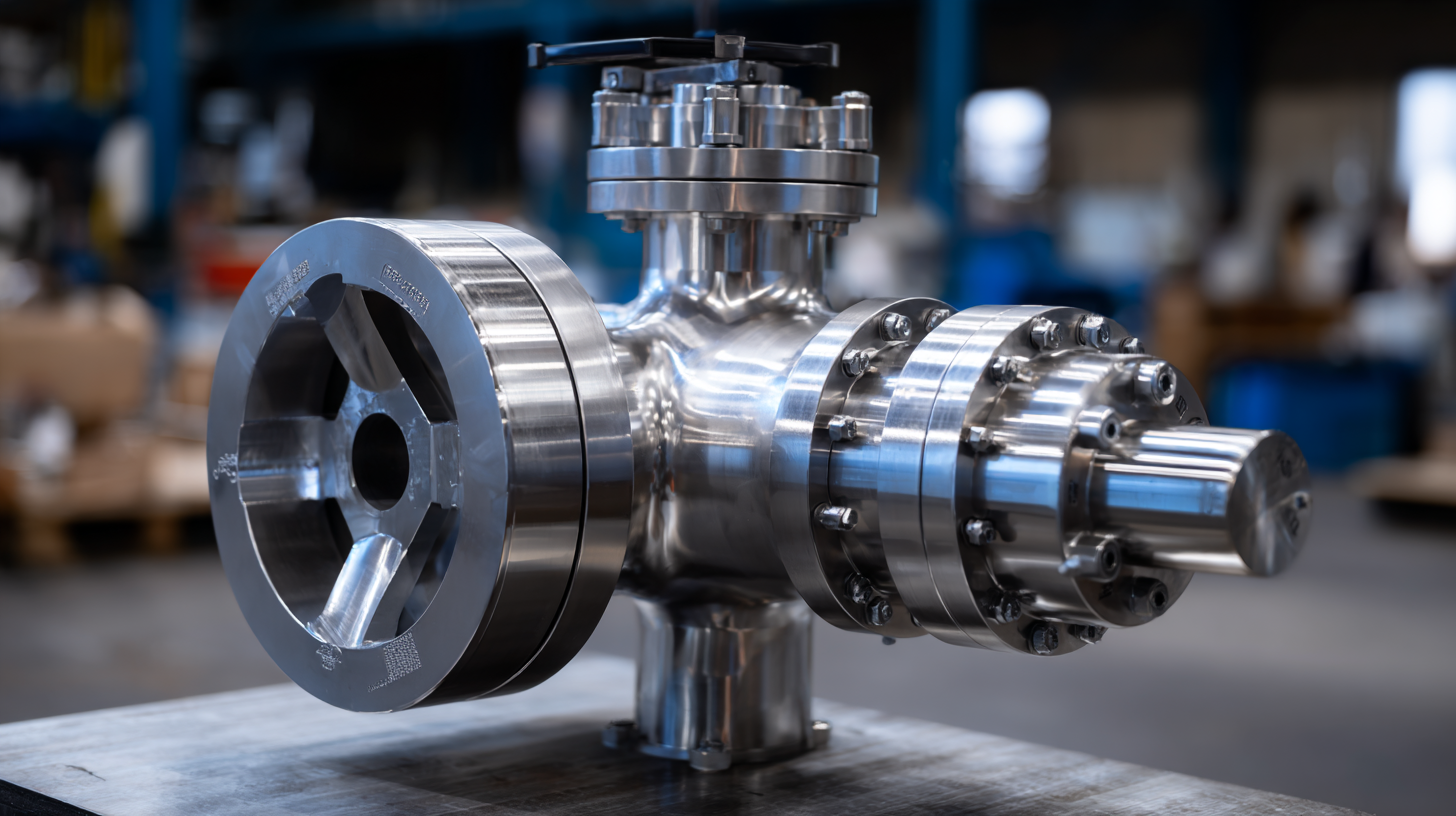

High pressure ball valves play a pivotal role in the management of aggressive fluids and gases, being essential for controlling flow in high-stakes environments.

According to a recent market report by Grand View Research, the global ball valve market is expected to reach USD 10.4 billion by 2025, with a significant share attributable to the rising demand for high pressure ball valves across sectors such as oil and gas, water treatment, and chemical processing.

These valves are known for their durability, reliability, and ability to withstand high pressures, making them indispensable in various applications.

Understanding how to choose the most suitable high pressure ball valve is key, as it can significantly impact efficiency, reduce downtime, and enhance the safety of industrial operations.

This guide provides essential tips and insights to equip professionals with the knowledge needed for making informed decisions in valve selection.

High pressure ball valves play a pivotal role in the management of aggressive fluids and gases, being essential for controlling flow in high-stakes environments.

According to a recent market report by Grand View Research, the global ball valve market is expected to reach USD 10.4 billion by 2025, with a significant share attributable to the rising demand for high pressure ball valves across sectors such as oil and gas, water treatment, and chemical processing.

These valves are known for their durability, reliability, and ability to withstand high pressures, making them indispensable in various applications.

Understanding how to choose the most suitable high pressure ball valve is key, as it can significantly impact efficiency, reduce downtime, and enhance the safety of industrial operations.

This guide provides essential tips and insights to equip professionals with the knowledge needed for making informed decisions in valve selection.

Key Factors to Consider When Selecting High Pressure Ball Valves for Industry

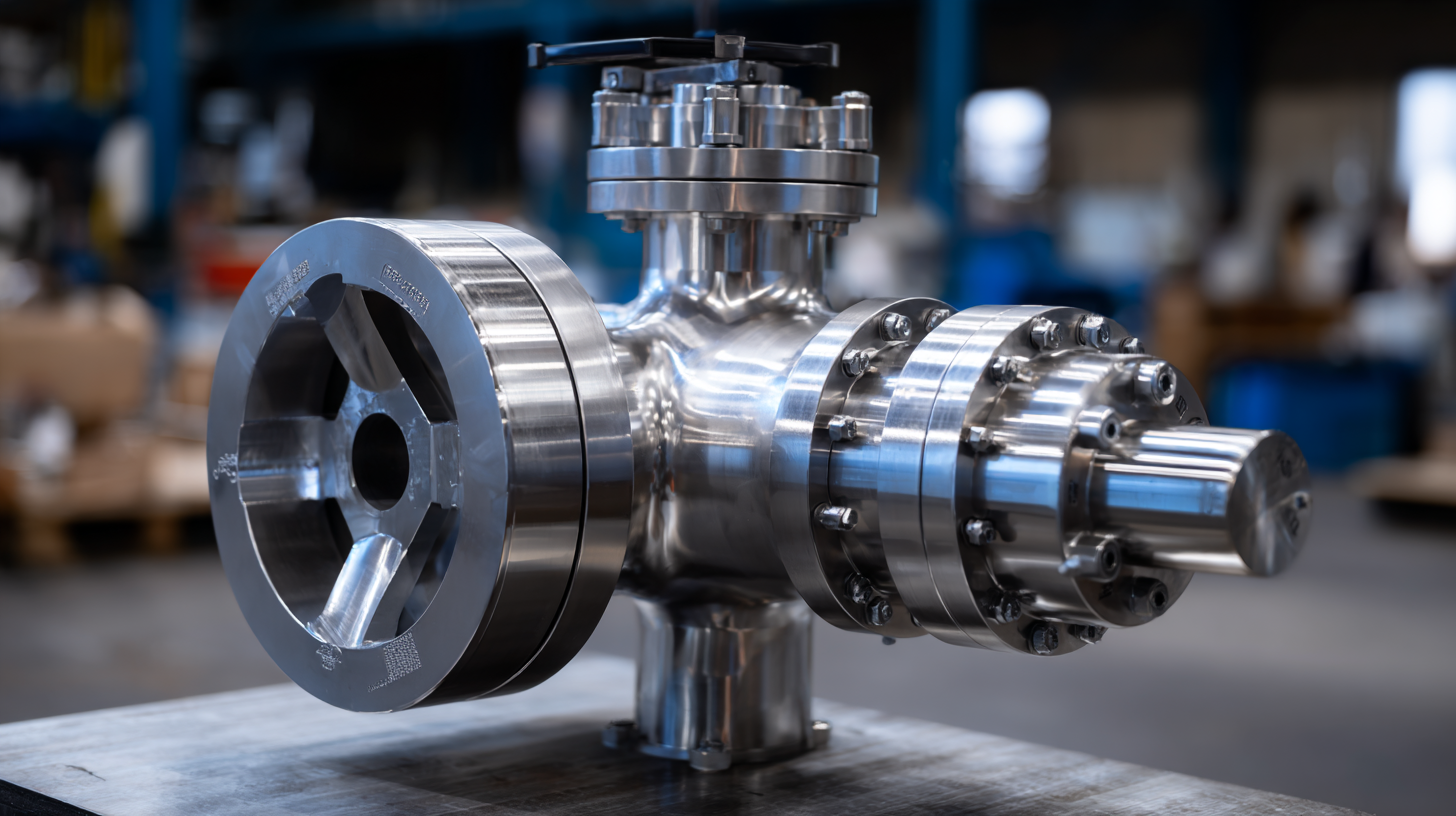

When selecting high pressure ball valves for industrial applications, there are several key factors to consider that can significantly enhance operational efficiency. Firstly, understanding the operating pressure and temperature ranges is crucial. According to the "Global Ball Valve Market Report 2022," the demand for high pressure ball valves is projected to grow by 5.1% annually, driven by their widespread use in sectors such as oil and gas, chemicals, and water management. Ensuring that the selected valve can withstand the specific conditions of your application is essential for maintaining system integrity.

Another critical factor is the valve material. Valves made from stainless steel or high-performance alloys are preferred for high pressure environments due to their excellent corrosion resistance and durability. A study published by the "Chemical Engineering Journal" highlights that the right material choice can extend the lifespan of ball valves by up to 30%, reducing the need for frequent replacements and maintenance. Additionally, compatibility with the fluid media being handled is vital to prevent leaks and ensure safety. By carefully evaluating these elements, industries can optimize their processes and reduce the long-term costs associated with valve failures.

Top 5 Benefits of Using High Pressure Ball Valves in Industrial Applications

High pressure ball valves are essential components for many industrial applications, offering numerous advantages that enhance operational efficiency. One of the primary benefits is their exceptional sealing capability, which prevents leaks in high-pressure environments. This feature not only safeguards the integrity of the system but also reduces potential downtime caused by maintenance or repairs, ensuring that operations run smoothly and efficiently.

High pressure ball valves are essential components for many industrial applications, offering numerous advantages that enhance operational efficiency. One of the primary benefits is their exceptional sealing capability, which prevents leaks in high-pressure environments. This feature not only safeguards the integrity of the system but also reduces potential downtime caused by maintenance or repairs, ensuring that operations run smoothly and efficiently.

Another significant advantage is the rapid operation of these valves. High pressure ball valves can quickly open and close with minimal effort, which is crucial in processes requiring swift control over flow rates. This responsiveness translates into better process control and reduced risk of accidents in high-stakes industrial settings. Additionally, their robust construction allows them to withstand extreme conditions, making them ideal for use in diverse environments, from oil and gas to chemical processing. Overall, the adoption of high pressure ball valves is a strategic choice for industries looking to improve system reliability and safety.

Comparative Analysis: High Pressure Ball Valves vs. Traditional Valve Types

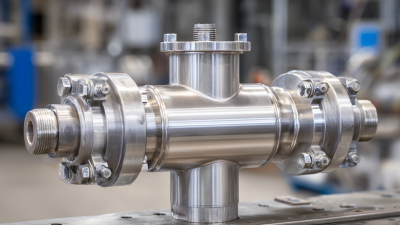

When evaluating high pressure ball valves compared to traditional valve types, it's essential to consider several key factors that influence performance and efficiency in industrial applications. High pressure ball valves, known for their robust construction and ability to handle severe pressures, offer advantages such as lower torque requirements and faster operation compared to gate or globe valves. Their quarter-turn operation allows for quick opening and closing, making them ideal for systems where responsiveness is crucial.

Additionally, the choice of materials significantly impacts the overall performance of these valves. Stainless steel and alloy-based options offer enhanced corrosion resistance and durability, making them suitable for a wide range of applications. In contrast, traditional valves may require more frequent maintenance and replacement due to wear and tear, especially in high-pressure settings. The comparative analysis highlights that while traditional valves still serve their purpose, high pressure ball valves are increasingly favored for their efficiency, reliability, and minimal energy loss, thus making them a superior choice for modern industrial environments.

Best Materials for High Pressure Ball Valves to Ensure Durability and Performance

Selecting the right materials for high pressure ball valves is crucial for ensuring durability and optimal performance in industrial applications. According to a study conducted by the Flow Control Division of the International Society of Automation, approximately 30% of valve failures in high-pressure systems are attributed to material degradation. Therefore, it is essential to choose materials that can withstand aggressive media, temperature fluctuations, and high-pressure environments.

Stainless steel is a widely accepted choice for high pressure ball valves due to its excellent corrosion resistance and tensile strength. A report from the Valve Manufacturers Association highlights that valves made from 316 stainless steel can endure environments with temperatures up to 1200°F and are ideal for harsh chemical processes. Additionally, high-performance plastics, such as PTFE (Polytetrafluoroethylene), are gaining popularity in applications where media compatibility and low friction are paramount. The use of PTFE in high pressure ball valves can lead to a reduction in wear and tear, extending the valve's lifespan significantly, as noted in research by the American Society of Mechanical Engineers.

Furthermore, the integration of advanced coatings, such as PVD (Physical Vapor Deposition), can enhance the surface properties of valve components, providing additional resistance to wear and corrosion. As industries evolve, selecting the right materials based on empirical data and industry insights is fundamental to achieving not only operational efficiency but also long-term reliability in high pressure applications.

Common Mistakes to Avoid When Choosing High Pressure Ball Valves for Your Facility

When selecting high pressure ball valves for industrial applications, facilities often overlook critical factors that can lead to inefficiencies and increased operational costs. One common mistake is neglecting the valve materials and their compatibility with the fluids being handled. According to a report by the International Society for Automation, using inappropriate materials can lead to premature failure and costly downtime, with industries losing up to 20% of their maintenance budget on valve-related issues. It is crucial to assess chemical compatibility charts and ensure that the selected materials can withstand the operational pressures and temperatures.

Another frequent error is underestimating the importance of valve sizing and flow rate specifications. Improper sizing can result in inadequate flow capacity or excessive pressure drops, negatively impacting system performance. A study by the Valve Manufacturers Association indicates that nearly 30% of facilities experience flow issues due to incorrectly sized valves. Properly calculating the required flow rate and matching it with the right ball valve size can enhance efficiency, reduce energy consumption, and extend the lifecycle of the system. Ensuring these aspects are thoroughly evaluated can prevent unnecessary costs and facilitate smooth operations in industrial settings.

The Ultimate Guide to Choosing High Pressure Ball Valves for Efficient Industrial Applications

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

High pressure ball valves play a pivotal role in the management of aggressive fluids and gases, being essential for controlling flow in high-stakes environments.

According to a recent market report by Grand View Research, the global ball valve market is expected to reach

High pressure ball valves play a pivotal role in the management of aggressive fluids and gases, being essential for controlling flow in high-stakes environments.

According to a recent market report by Grand View Research, the global ball valve market is expected to reach  High pressure ball valves are essential components for many industrial applications, offering numerous advantages that enhance operational efficiency. One of the primary benefits is their exceptional sealing capability, which prevents leaks in high-pressure environments. This feature not only safeguards the integrity of the system but also reduces potential downtime caused by maintenance or repairs, ensuring that operations run smoothly and efficiently.

High pressure ball valves are essential components for many industrial applications, offering numerous advantages that enhance operational efficiency. One of the primary benefits is their exceptional sealing capability, which prevents leaks in high-pressure environments. This feature not only safeguards the integrity of the system but also reduces potential downtime caused by maintenance or repairs, ensuring that operations run smoothly and efficiently.