How to Choose the Right Globe Valves for Your Piping System Needs

When it comes to optimizing a piping system, selecting the appropriate globe valves is critical for ensuring efficiency and reliability. According to a report published by the Global Valve Market Research Company, the globe valve sector is poised to experience a compound annual growth rate (CAGR) of 5.5% over the next five years, driven by increasing demand across various industries, including oil and gas, water utilities, and power generation. As the complexity and requirements of modern applications evolve, understanding the unique specifications and advantages of globe valves becomes essential for engineers and system designers.

Expert insight into the significance of choosing the right globe valves can be found in a statement from industry specialist Dr. John Thompson, who emphasizes, "Selecting the correct valve not only impacts the system's operational effectiveness but also contributes to its longevity and maintenance costs." Each type of globe valve presents distinct characteristics, whether it is concerning pressure ratings, temperature tolerances, or materials of construction. Thus, discerning the right fit for a given application can greatly influence overall performance and sustainability in piping systems. By thoroughly assessing these factors, industry professionals can make informed decisions that align with their operational needs and long-term objectives.

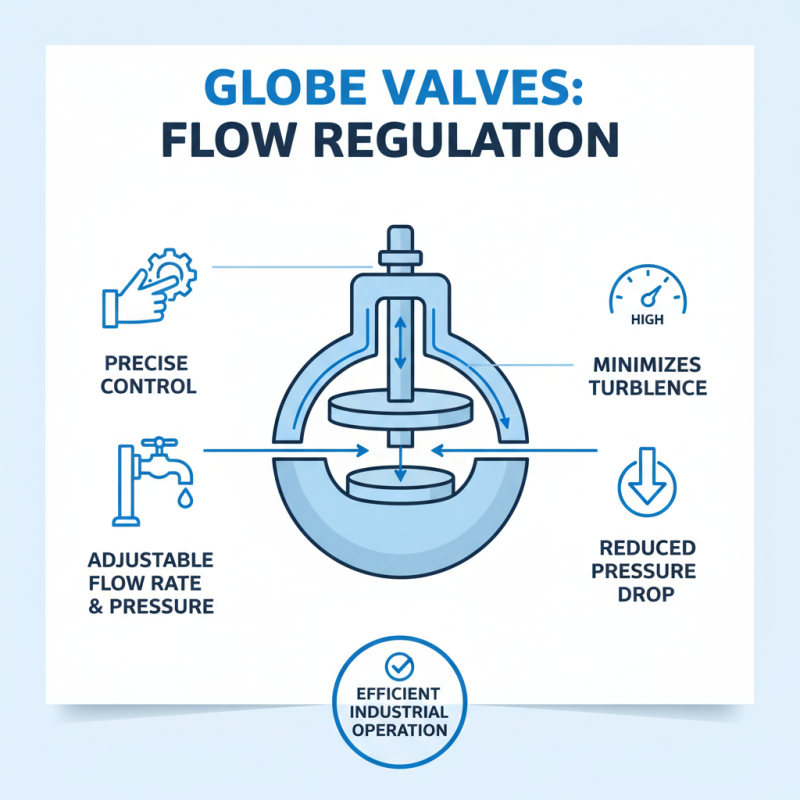

Understanding the Functionality of Globe Valves in Piping Systems

Globe valves play a crucial role in regulating the flow of liquids and gases within piping systems. Their distinctive design, characterized by a spherical body and a movable disk, allows for precise control over flow rate and pressure. This functionality makes globe valves particularly suitable for applications where flow needs to be adjusted frequently and with accuracy. The shape of the valve body helps to minimize turbulence and pressure drop, ensuring a more efficient operation in various industrial settings.

One of the key advantages of using globe valves in piping systems is their ability to provide a tight seal, thus reducing the risk of leaks. Unlike other types of valves, the seating mechanism in globe valves is designed to minimize wear and tear, contributing to their longevity and reliability. They are also versatile, being utilized in both high and low-pressure systems. When selecting globe valves for specific applications, it's essential to consider factors such as material compatibility, pressure ratings, and the type of fluid being transported. By understanding these aspects, engineers can better determine the right globe valves that will enhance the performance and safety of their piping systems.

Key Factors to Consider When Selecting Globe Valves

When selecting globe valves for your piping system, it's crucial to consider several key factors that can significantly impact performance and efficiency. One primary aspect is the valve material, as it influences not only the durability and corrosion resistance but also the compatibility with the fluid being handled. According to a report by the World Pump Market, a wrong material choice can reduce valve lifespan by up to 30%, increasing maintenance costs and downtimes.

Another important consideration is the valve size and connection type. An improperly sized globe valve can lead to reduced flow efficiency and increased pressure drop, resulting in operational inefficiencies. The Hydraulic Institute states that ensuring the right sizing can improve system efficiency by 15-20%. Additionally, it's vital to assess the pressure and temperature ratings of the globe valve, as they must align with the operating conditions of your piping system to prevent failures and disruptions.

Lastly, the flow characteristics of the globe valve play a critical role in its performance. Different designs can impact how fluid flows through the system, affecting not just efficiency but also noise and vibration levels. The American Society of Mechanical Engineers emphasizes that understanding the specific flow rate requirements can enhance system reliability and performance, making it essential to analyze these characteristics during the selection process.

Globe Valve Selection Criteria

Comparing Different Globe Valve Materials and Their Applications

When selecting globe valves for your piping system, considering the material is crucial as it directly influences performance and durability. Common materials for globe valves include brass, stainless steel, and cast iron, each offering unique benefits for different applications.

Brass valves are known for their corrosion resistance and are suitable for low-pressure applications, typically in water and air systems. Their lightweight and economical nature makes them a popular choice for residential and commercial plumbing.

On the other hand, stainless steel valves are favored for their excellent resistance to high temperatures and pressures, making them ideal for industrial applications, including chemical and petroleum processes. They provide enhanced durability and reliability, particularly in aggressive environments.

Cast iron valves, while heavier, are appreciated for their robustness and ability to handle steam and water in larger systems, often seen in municipal projects and heating applications. Understanding the specific requirements of your piping system, such as temperature, pressure, and fluid characteristics, will guide you in choosing the most suitable globe valve material for optimal performance.

Sizing and Pressure Ratings for Optimal Globe Valve Performance

When selecting globe valves for your piping system, understanding sizing and pressure ratings is crucial for optimal performance. The American Society of Mechanical Engineers (ASME) outlines that globe valves are designed to control flow in a pipeline, and their effectiveness heavily depends on accurate sizing. Valves must be sized to match the flow rates of the system; typically, a minimum flow velocity of 3-5 feet per second is recommended to avoid sedimentation and achieve stable flow characteristics. Sizing a globe valve too large can lead to insufficient sealing and vibration issues, while an undersized valve may not handle the required flow, leading to increased pressure drops and operational inefficiencies.

Pressure ratings are equally vital in ensuring that globe valves operate effectively under certain conditions. Industry standards such as the ASME B16.34 provide guidelines for pressure-temperature ratings that help professionals select the right valve for their specific applications. For instance, globe valves are generally available in various pressure classes—150, 300, 600, and even higher—depending on the material and design. It's important to match the valve’s pressure rating with the maximum system pressure to avoid catastrophic failures. Reports from the European Federation of Valve Manufacturers suggest that improper matching of pressure ratings and system requirements can lead to valve failures in up to 25% of cases, causing not only performance issues but also significant safety concerns. Therefore, assessing both the size and pressure rating is essential to ensure longevity and reliability in your piping systems.

How to Choose the Right Globe Valves for Your Piping System Needs - Sizing and Pressure Ratings for Optimal Globe Valve Performance

| Valve Size (inches) |

Pressure Rating (PSI) |

Body Material |

Temperature Rating (°F) |

| 1/2 |

150 |

Carbon Steel |

-20 to 300 |

| 3/4 |

300 |

Stainless Steel |

-40 to 400 |

| 1 |

600 |

Brass |

0 to 500 |

| 1.5 |

900 |

Alloy Steel |

-20 to 600 |

| 2 |

1500 |

Ductile Iron |

-20 to 750 |

Maintenance Tips for Ensuring Longevity of Globe Valves

When it comes to ensuring the longevity of globe valves in your piping system, regular maintenance is key. These valves, known for their ability to regulate flow effectively, require attention to keep them functioning at optimal levels. One vital maintenance tip is to routinely inspect the valve seats and seals for wear and tear. This can help prevent leaks and maintain proper sealing, ultimately prolonging the valve's lifespan.

Another important aspect of maintenance is to monitor operating conditions. Ensuring that the valve operates within its specified pressure and temperature ranges will reduce the risk of premature failure. Regularly greasing or lubricating moving parts can also minimize friction and wear.

When it comes time to replace a globe valve, remember to check the compatibility of materials with the fluids being handled, ensuring that the new valve will meet the demands of the system.

Lastly, consider implementing a schedule for professional inspections. Qualified technicians can identify potential issues before they escalate, allowing for timely repairs that can save both time and costs in the long run. By following these maintenance tips, you can ensure that your globe valves will not only perform well but also enjoy a long, reliable service life.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.