2026 How to Choose the Right Knife Gate Valve for Your Needs

Choosing the right knife gate valve is essential. Industry expert John Stevens often says, "The right valve can make all the difference." Understanding your needs is crucial in this complex market.

Knife gate valves are vital in various applications, from water treatment to mining. Their design allows for efficient flow control. However, selecting the wrong model can lead to issues. It’s not just about specifications; installation and maintenance matter too.

Consider the materials, pressure ratings, and sizes. Each part plays a role in performance. There are numerous options available, and navigating this can be overwhelming. Reflect on your specific requirements. Every detail counts, and sometimes, it's easy to overlook them.

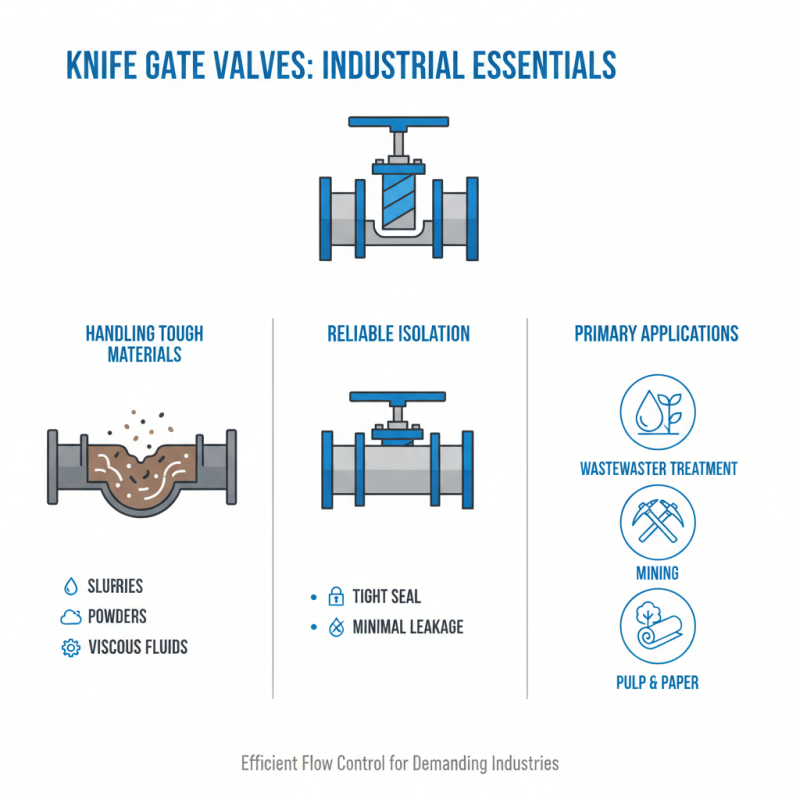

Understanding Knife Gate Valves and Their Applications

Knife gate valves are essential components in various industries. They excel in handling slurries, powders, and other viscous materials. These valves provide reliable isolation in pipelines, making them ideal for wastewater treatment, mining, and pulp and paper applications. Their design allows for a tight seal with minimal leakage.

When selecting a knife gate valve, consider the material of construction. Corrosion resistance is crucial for longevity and performance. The size of the valve must match the pipeline specifications to ensure proper flow. Pay attention to the actuator type, manual or electric, depending on your system requirements. Sometimes, the choice between automatic or manual operation can be confusing.

It's easy to overlook maintenance needs. Regular checks prolong the valve’s life and improve efficiency. Installation can also pose challenges if not done correctly. Misalignment can lead to leaks and operational issues. By understanding these factors, you can make a more informed decision when choosing the right knife gate valve for your needs.

Key Considerations for Selecting Knife Gate Valves

When selecting a knife gate valve, several key considerations come into play. The valve’s construction material is crucial. Different applications require specific materials to ensure durability and performance. For instance, stainless steel is ideal for corrosive environments, while ductile iron suits general uses. A recent industry report highlights that over 35% of valve failures stem from improper material choice.

Another important aspect is the valve’s size and pressure rating. Users must match the valve to the system’s specifications. An incorrect size can lead to leaks or insufficient flow control. According to a study by Flow Control Magazine, nearly 25% of operational issues in industrial settings are linked to valve sizing errors.

Lastly, consider the type of sealing mechanism. A proper seal is vital for preventing leakage. Different designs offer varying levels of effectiveness, especially in challenging environments. Users need to weigh the longevity and maintenance of seals against initial costs. This balance often reveals areas for improvement in long-term operational strategies. Always reassess your choice as system requirements evolve.

Key Considerations for Selecting Knife Gate Valves

Materials and Design Features to Evaluate

When selecting a knife gate valve, materials and design features are critical. The valve's construction material significantly impacts durability. Common options include stainless steel, cast iron, and plastic. Each has its advantages and drawbacks. Stainless steel offers corrosion resistance but may be expensive. Cast iron is robust but can rust if not maintained. Plastic valves are lightweight but may not handle high pressure well.

Design features can also affect functionality. Consider the valve's sealing mechanism. A good seal prevents leaks and ensures efficiency. Look for features like adjustable seats and robust gate design. Also, assess the actuator type. Manual, pneumatic, and electric options all have unique benefits. A manual actuator might be simpler but less efficient for large operations.

Reflect on your specific needs and operational environment. Temperature and pressure conditions are vital. Not all valves perform well under extreme situations. FUTURE adaptability can be an overlooked aspect. Will your needs change over time? A flexible design might help accommodate future demands. Choosing wisely involves weighing these factors carefully to find the best fit for your application.

Sizing and Pressure Ratings of Knife Gate Valves

When selecting a knife gate valve, understanding sizing and pressure ratings is vital. The right size ensures efficient flow management. A valve too small might restrict flow, leading to pressure buildup. Conversely, an oversized valve can lead to leaks. Measure the pipe diameter accurately. This contributes to a long-lasting solution.

Track the system's pressure ratings. Each valve has specific ratings that determine its suitability for various applications. Check the maximum pressure the valve can handle. If the pressure exceeds this, it may fail. Sometimes, users overlook pressure requirements. This can lead to costly errors.

Consider the material and design as well. Some valves perform better under certain conditions. It’s crucial to evaluate the operational environment. A mismatch can affect the valve's longevity. This choice is not always straightforward. It requires careful thought and sometimes revisions. Being meticulous in these aspects can make all the difference.

2026 How to Choose the Right Knife Gate Valve for Your Needs - Sizing and Pressure Ratings of Knife Gate Valves

| Valve Size (Inches) |

Pressure Rating (PSI) |

Body Material |

Seat Material |

Operating Temperature (°F) |

| 2 |

150 |

Cast Iron |

NBR |

-20 to 180 |

| 3 |

150 |

Stainless Steel |

EPDM |

-20 to 250 |

| 4 |

300 |

Carbon Steel |

PTFE |

-20 to 400 |

| 6 |

150 |

Ductile Iron |

NBR |

-20 to 180 |

| 8 |

300 |

Stainless Steel |

EPDM |

-20 to 250 |

Maintenance and Operational Best Practices for Knife Gate Valves

Knife gate valves are essential for controlling flow in various industrial applications. Proper maintenance is crucial for smooth operations. Regular inspections help identify issues early. Check for signs of wear, rust, or any unusual noises during operation. A simple visual check can make a difference.

Operational best practices ensure longevity and performance. Keep the valve clean and free from debris. Ensure that the actuator functions correctly. Tighten all connections periodically. Ignoring small issues can lead to larger problems later. Consistent monitoring can prevent unexpected failures.

Training your staff on proper usage is essential. They need to understand the specific application of the valve. Misuse can cause wear or damage. Regular feedback sessions can help team members share experiences. This fosters a culture of continuous improvement.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.