How to Choose the Right Wafer Butterfly Valve for Your Project

In the realm of fluid control systems, the selection of components is critical to ensure optimal performance and reliability. One such component that has gained remarkable prominence in various industrial applications is the wafer butterfly valve. According to recent market analysis, the global butterfly valve market is projected to reach $6.82 billion by 2027, with a significant demand driven by the increasing need for effective fluid management in sectors such as water treatment, oil and gas, and chemical processing.

When choosing the right wafer butterfly valve for your project, factors such as material selection, size, pressure rating, and application-specific requirements become paramount. Industry reports indicate that wafer butterfly valves account for approximately 20% of the total valve market share due to their lightweight design, ease of installation, and capability to handle high flow rates. This underscores the necessity for engineers and project managers to have a clear understanding of the various options available, ensuring that their chosen valve will meet the project’s operational demands while adhering to budget constraints.

Thus, this guide aims to provide critical insights into selecting the appropriate wafer butterfly valve, enabling stakeholders to make informed decisions that will enhance efficiency and sustainability in their operations.

Understanding the Basics of Wafer Butterfly Valves: Key Features and Benefits

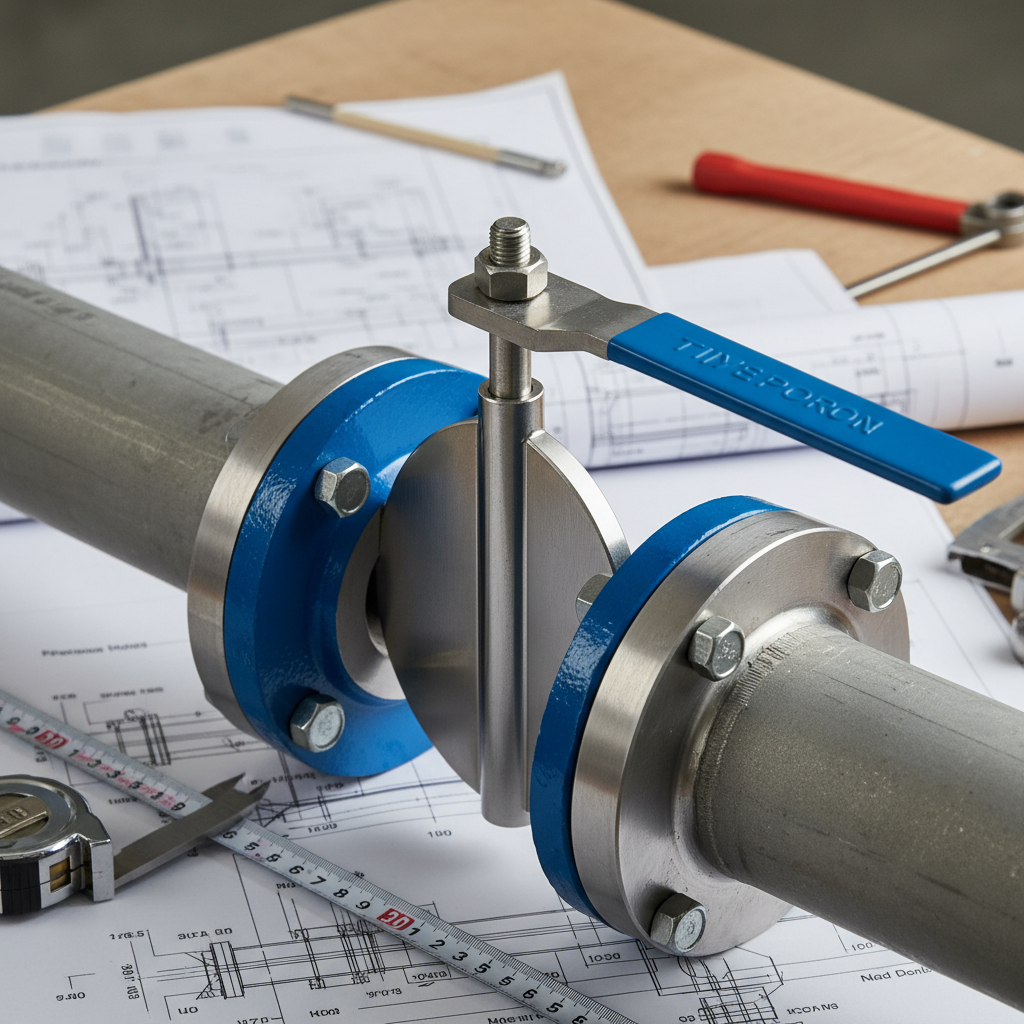

Wafer butterfly valves are essential components in many fluid control applications, known for their lightweight design and compact construction. These valves consist of a rotating disc that regulates flow, making them ideal for on/off and throttling operations. One of the main advantages of wafer butterfly valves is their ability to handle a wide range of temperatures and pressures, which can be crucial depending on the specific needs of your project. Additionally, their minimal space requirements allow for easy installation in tight spaces, making them a popular choice in various industries.

Tips for Selection: When choosing the right wafer butterfly valve, consider the material construction. Different materials, such as stainless steel, PVC, and ductile iron, have various resistance levels to corrosion, chemicals, and temperature changes. This affects not only the valve's performance but also its longevity. Also, ensure the valve size matches the pipe diameter, and think about the actuator type. Deciding between manual or automated actuation can significantly impact the valve’s operational efficiency.

Another key feature to assess is the valve’s flow characteristics. Look for valves designed to minimize turbulence, as this can enhance performance and reduce energy consumption. Checking the valve's certification and compliance with relevant industry standards ensures reliability and safety for your project environment. Remember, understanding your project's specific requirements will guide you in selecting the most suitable wafer butterfly valve.

Identifying Project Requirements: Size, Pressure, and Material Considerations

When selecting a wafer butterfly valve for a specific project, it is essential to begin with a clear understanding of the project's requirements, particularly concerning size, pressure, and material. The size of the valve must align with the piping system, ensuring that it fits seamlessly within the existing infrastructure. Incorrect sizing can lead to inefficiencies, increased wear, or even system failures. Therefore, proper measurements of the pipe diameter, as well as consideration for any space constraints, are critical in making an informed choice.

Next, assessing the pressure ratings of the valve is vital. Different applications will have varying pressure needs, and it is imperative to choose a valve that can withstand these conditions. Valves typically have designated pressure ratings, and selecting one that exceeds the system's maximum pressure can help avoid potential failures. Lastly, the material of the wafer butterfly valve should be compatible with the media it will regulate. Factors such as corrosion resistance, temperature fluctuations, and chemical compatibility must be considered to ensure durability and optimal performance in the long run. By comprehensively evaluating these aspects, one can make a more informed decision when selecting a valve for their project.

Evaluating Valve Performance: Flow Capacity and Leakage Rates

When selecting the right wafer butterfly valve for your project, understanding valve performance is crucial, specifically focusing on flow capacity and leakage rates. According to a recent industry report by the Flow Control Institute, the flow capacity of a butterfly valve can be significantly impacted by its design and size, with optimized models providing up to 50% better flow efficiency compared to standard options. Properly sizing the valve to your system's requirements ensures that it operates efficiently and minimizes energy loss.

Leakage rates, an essential performance metric, can indicate the reliability and longevity of a valve. The American Valve Manufacturers Association (AVMA) recommends selecting butterfly valves with a maximum leakage rate classified under ISO 5208 standards for critical applications. Valves designed with high performance elastomer seals can achieve leakage rates as low as 0.5% of the maximum flow capacity, making them ideal for demanding environments.

Tips: Always conduct a thorough analysis of your project's specific flow conditions to determine the most suitable valve size and type. It’s essential to consult with manufacturers to acquire accurate data on flow capacities and leakage rates, ensuring that you select a valve that not only meets operational requirements but also maintains efficiency over time. Regular maintenance and testing should also be incorporated to evaluate the performance of installed valves, especially in long-term applications.

How to Choose the Right Wafer Butterfly Valve for Your Project - Evaluating Valve Performance: Flow Capacity and Leakage Rates

| Valve Size (inches) |

Flow Capacity (CV) |

Leakage Rate (ANSI Class) |

Pressure Rating (PSI) |

| 2 |

27 |

Class VI |

150 |

| 3 |

41 |

Class IV |

150 |

| 4 |

84 |

Class V |

150 |

| 6 |

215 |

Class IV |

150 |

| 8 |

450 |

Class III |

150 |

Comparing Design Options: Standard vs. High-Performance Wafer Butterfly Valves

When selecting a wafer butterfly valve for your project, understanding the distinctions between standard and high-performance options is crucial.

Standard wafer butterfly valves are typically designed for general applications, offering a reliable solution for moderate flow control. These valves often consist of a simple design, making them cost-effective and easier to install.

They perform well under a wide range of conditions, making them suitable for numerous industrial applications.

On the other hand, high-performance wafer butterfly valves are engineered for more demanding situations.

These valves often incorporate advanced materials and design features to enhance durability, reduce flow resistance, and improve sealing capabilities.

They are ideal for applications involving high pressures, extreme temperatures, or corrosive environments.

When choosing between these two options, consider the specifics of your project, including fluid type, operating conditions, and budget constraints, to ensure optimal performance and longevity of the valve in your system.

Top Brands and Manufacturers: What to Look for in Quality Assurance and Support

When selecting a wafer butterfly valve for your project, understanding the significance of quality assurance and support from top brands and manufacturers is crucial. According to a report by Grand View Research, the global butterfly valve market is expected to reach USD 9.09 billion by 2025, driven by the demand for reliable automation solutions in various industries. Thus, choosing a reputable manufacturer can ensure that you receive a product that meets industry standards and boasts long-term performance.

Look for brands that adhere to international quality certifications such as ISO 9001 and API 609. These certifications indicate that the manufacturer has established a robust quality management system and compliance with industry norms. Additionally, consider the level of customer support offered; manufacturers that provide comprehensive post-sales support, including installation assistance and maintenance services, are invaluable. A survey conducted by MarketsandMarkets highlights that 70% of users prioritize manufacturers with strong technical support and warranty offers, signifying the importance of durable performance and customer satisfaction in the valve market.

Top Features of Wafer Butterfly Valves

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.