2025 How to Choose the Right Bypass Valve for Your System Needs

The selection of an appropriate bypass valve is pivotal in optimizing system performance and enhancing operational efficiency. According to the Global Bypass Valve Market Report, the industry is projected to witness a compound annual growth rate (CAGR) of 6.5% from 2020 to 2025, driven by the increasing need for reliable flow management in various applications, including water treatment, oil and gas, and manufacturing processes. Bypass valves play a crucial role in maintaining optimal flow rates, protecting equipment from damage, and ensuring that operations continue seamlessly during maintenance periods.

When choosing the right bypass valve, engineers and system designers must consider several key factors, such as the specific requirements of their applications, the fluid characteristics, and the operating conditions. The American Society of Mechanical Engineers (ASME) emphasizes that improper selection can lead to inefficiencies, increased operational costs, and reduced system reliability. By understanding the various types of bypass valves and their unique functionalities, decision-makers can make informed choices that align with their operational goals and contribute to long-term sustainability. Thus, the right bypass valve selection is not just a technical consideration but a critical factor for the overall success of industrial systems.

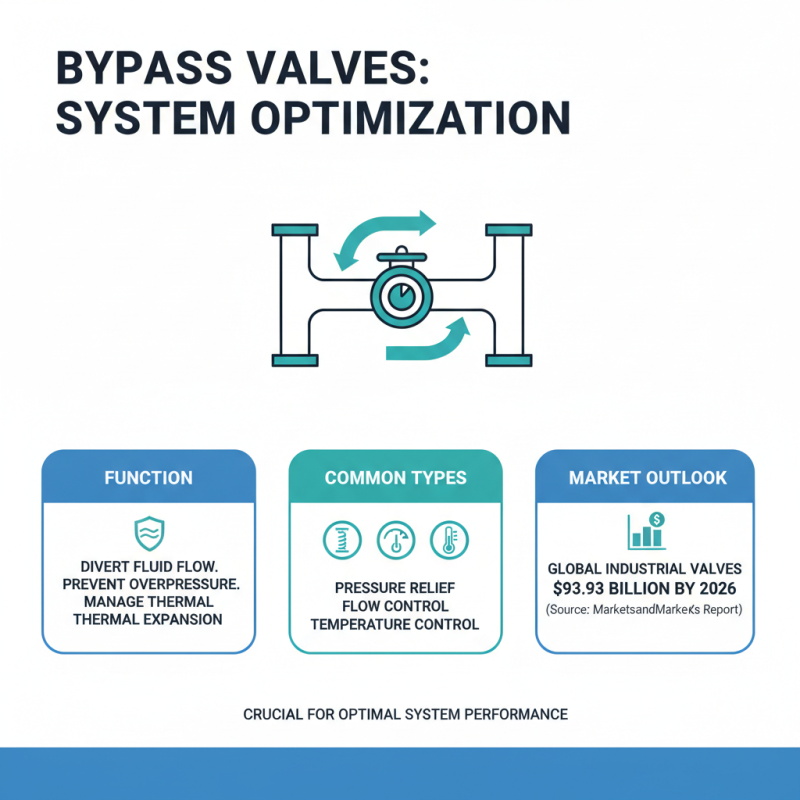

Understanding Bypass Valves: Function and Importance in System Design

Bypass valves play a crucial role in optimizing system performance across various applications. Their primary function is to redirect flow within a system to maintain pressure differentials and ensure efficiency. According to a report by the International Journal of Engineering Research and Applications, improper bypass valve selection can lead to significant losses in system efficiency, often exceeding 20%. This figure underscores the importance of understanding the specifications and operational requirements of your system when selecting a bypass valve.

Incorporating bypass valves into system design not only enhances functionality but also supports the longevity of equipment. For example, in hydraulic systems, bypass valves help in maintaining fluid temperature by allowing excess fluid to circulate back into the reservoir. A study from the American Society of Mechanical Engineers indicated that systems equipped with correctly specified bypass valves experience up to a 30% reduction in maintenance costs over time. This statistic highlights the critical balance between system reliability and operational efficiency, urging design engineers to prioritize appropriate bypass valve selection tailored to their specific system needs.

2025 How to Choose the Right Bypass Valve for Your System Needs

| Parameter |

Description |

Importance |

Recommendation |

| Flow Rate |

The volume of fluid passing through the valve per unit time. |

Critical for ensuring system efficiency and safety. |

Choose a valve with a suitable flow capacity. |

| Pressure Rating |

Maximum pressure the valve can withstand without failure. |

Ensures reliability under operational conditions. |

Select a valve rated above your system's maximum pressure. |

| Material |

The substance from which the valve is made (e.g., metal, plastic). |

Affects durability and compatibility with fluids. |

Match material with the type of fluid in your system. |

| Temperature Range |

Operating temperature limits for optimal performance. |

Prevents damage and extends valve life. |

Ensure the valve can handle the operating temperature. |

| Actuation Type |

How the valve is opened and closed (manual, pneumatic, electric). |

Impacts control and automation of the system. |

Choose based on the system's control requirements. |

Key Factors to Consider When Selecting a Bypass Valve for Your System

When selecting a bypass valve for your system, several key factors must be taken into account to ensure optimal performance and compatibility. First and foremost, it is essential to assess the pressure and temperature ratings of the valve, as these specifications must align with your system's operational parameters. Understanding the flow characteristics is also critical — factors such as valve size, type, and lift height can significantly influence the efficiency and responsiveness of your system. A valve that is too small may restrict flow, while one that is too large could lead to system inefficiencies.

Another vital consideration is the material of the valve itself. Different applications may require specific materials to withstand environmental challenges such as corrosion, wear, or chemical exposure. It is also important to analyze the control mechanisms available, as options range from manual to automated systems, each offering varying levels of precision and responsiveness. Ultimately, understanding your system's specific needs and the operational environment will guide you in choosing the most suitable bypass valve to maximize efficiency and reliability in your operations.

Bypass Valve Selection Factors

This chart illustrates the key factors to consider when selecting a bypass valve for your system needs. The importance rating reflects how critical each factor is in the decision-making process.

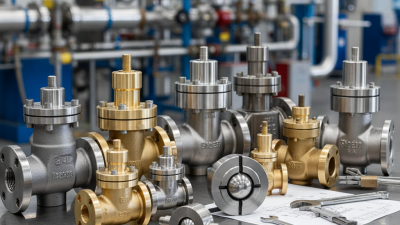

Common Types of Bypass Valves and Their Applications in Various Industries

In various industries, choosing the right bypass valve is crucial for optimizing system performance. Bypass valves are designed to divert fluid flow in a system, preventing damage from overpressure and allowing for thermal expansion management. Common types include pressure relief valves, flow control valves, and temperature control valves, each tailored to meet specific operational requirements. According to a report by MarketsandMarkets, the global market for industrial valves is projected to reach USD 93.93 billion by 2026, highlighting the growing importance of these components across sectors.

In the oil and gas industry, pressure relief valves are vital for safeguarding equipment from excessive pressure, ensuring safety and efficiency. Similarly, in water treatment facilities, flow control valves regulate the flow of water, playing a significant role in maintaining water quality and system stability. The chemical processing sector utilizes temperature control valves to manage exothermic reactions, underscoring the versatility of bypass valves. Research from Grand View Research indicates that the chemical processing segment alone accounts for over 30% of the industrial valve market, illustrating the diverse applications of bypass valves across different operational environments.

Evaluating Performance Metrics: Flow Rate, Pressure Drop, and Material Compatibility

When selecting a bypass valve for your system, evaluating performance metrics is crucial. The flow rate, which indicates the volume of fluid that can pass through the valve within a given time, is a primary consideration. A valve with an insufficient flow rate may lead to system inefficiencies, while one that exceeds requirements could cause excessive wear and tear on the system components. Therefore, understanding the specific demands of your application will guide you in choosing a bypass valve that maintains optimal performance without introducing unnecessary complications.

Another key metric is pressure drop, which refers to the reduction in pressure as fluid flows through the valve. A significant pressure drop can negatively impact system performance, causing pumps to work harder and potentially leading to energy inefficiencies. It's essential to select a bypass valve that minimizes pressure drop while still accommodating the required flow rate. Additionally, ensuring material compatibility with the fluids in your system is vital, as it affects the durability and functionality of the valve. Selecting materials that resist corrosion and wear can prolong the life of the valve and help maintain the integrity of your entire system.

Best Practices for Installation and Maintenance of Bypass Valves in Systems

When it comes to the installation of bypass valves, proper procedures are essential to ensure optimal performance and longevity of your system. First, it is vital to carefully assess the valve size and type that matches your system's specifications. Prior to installation, ensure that the surrounding area is clean and free from debris, as contaminants can affect valve operation. Additionally, follow the manufacturer’s guidelines, paying close attention to torque specifications when securing the bolts, which helps prevent leaks and ensures a tight seal.

Regular maintenance of bypass valves is equally crucial for their efficient functioning. Schedule routine inspections to check for signs of wear or corrosion that could hinder performance. Regularly lubricate moving parts as specified to avoid sticking or malfunction. Furthermore, it is important to monitor the system for fluctuations in pressure or flow rates, as these can indicate potential issues with the bypass valve. Documentation of maintenance activities not only helps in tracking valve performance over time but also assists in identifying any recurring issues that may need addressing. Proper installation and diligent maintenance practices will enhance the reliability and efficiency of bypass valves in any system configuration.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.