How to Choose the Right Knife Valve for Your Application Needs

Selecting the appropriate knife valve for your specific application is crucial in maximizing efficiency and performance in various industrial processes. According to James Anderson, a leading expert in valve technology, "The right knife valve not only enhances flow control but also significantly reduces maintenance costs." As industries continue to evolve with advanced technologies, understanding the features, materials, and designs of knife valves becomes paramount for engineers and procurement specialists alike.

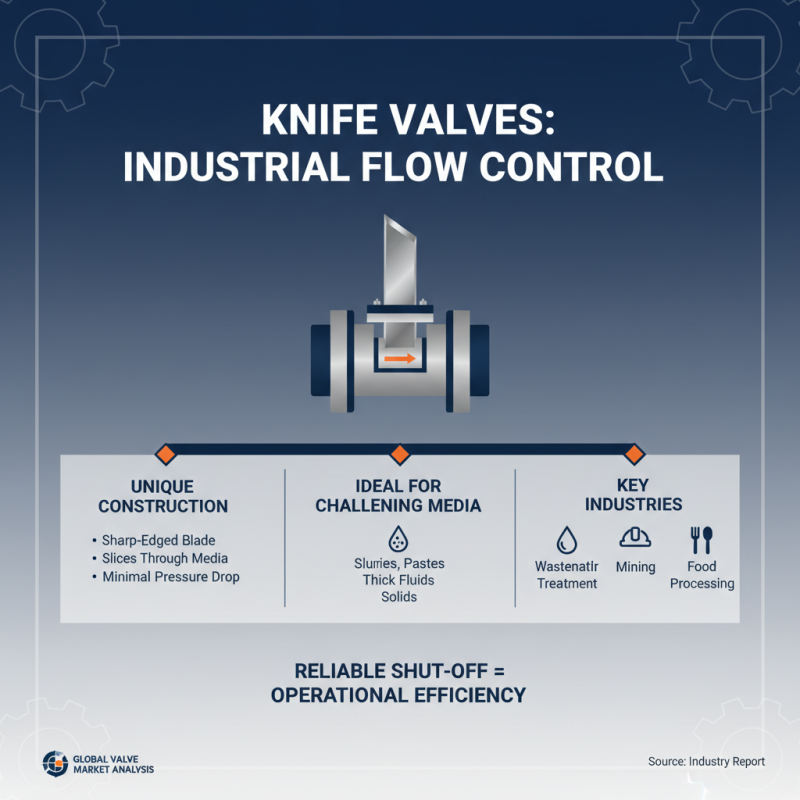

Knife valves are primarily used for on-off service in systems where a tight seal is essential. Their unique design, with a sharp-edged blade, allows for effective cutting through solids and slurries, making them ideal for industries such as wastewater treatment, mining, and pulp and paper. With numerous configurations and materials available, selecting the proper knife valve involves a careful assessment of the specific requirements of the application, including pressure, temperature, and media characteristics.

In this guide, we will explore the critical factors to consider when choosing a knife valve, ensuring that you not only meet the operational demands but also align with best practices for safety and efficiency. Understanding these elements will empower you to make informed decisions that optimize your systems and enhance overall productivity.

Understanding Knife Valves and Their Applications

Knife valves are specialized industrial components designed to control the flow of materials, particularly in applications involving slurries, pastes, or other challenging media. Their unique construction features a sharp-edged blade that slices through materials, allowing for precise control and minimal pressure drop. According to a report by the Global Valve Market Analysis, knife valves are increasingly favored in industries such as wastewater treatment, mining, and food processing, where reliable shut-off capabilities are crucial for operational efficiency.

When selecting a knife valve, it's essential to consider the specific application requirements. Parameters such as the type of material being handled, temperature, pressure, and potential for erosion can influence performance. For instance, a recent study highlighted that over 40% of industrial valve failures can be attributed to material compatibility issues. Thus, ensuring that the knife valve materials align with the application's needs is vital for longevity and effectiveness.

**Tips:** When integrating knife valves into your system, ensure a proper installation to prevent leaks and maximize efficiency. Regular maintenance checks can also prolong valve lifespan and enhance performance. It's advisable to consult with an industry expert to tailor the valve choice to your operational needs, which can save on costs and improve reliability in the long term.

Key Factors to Consider When Choosing a Knife Valve

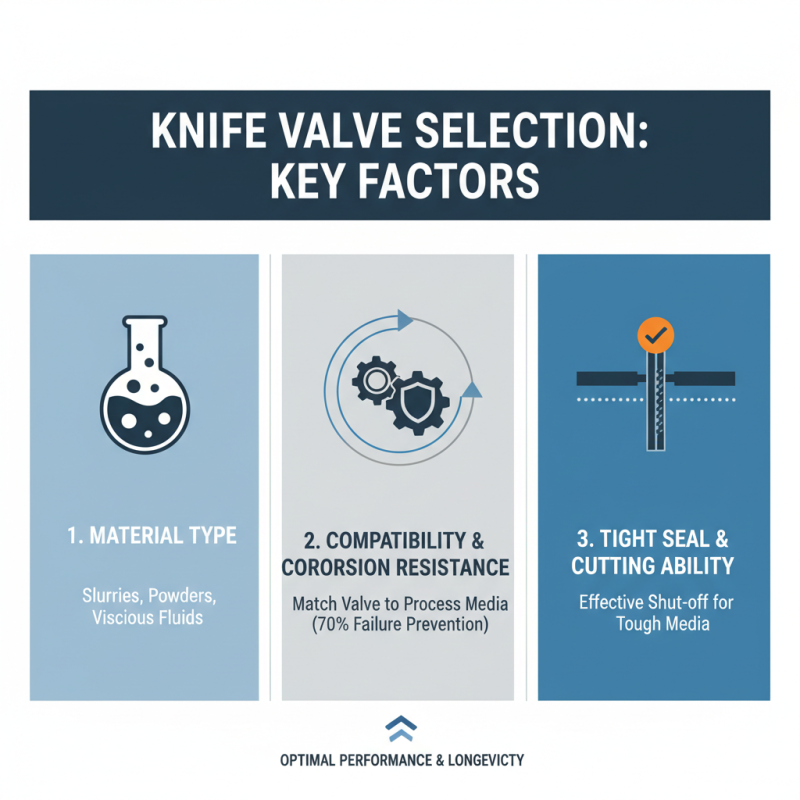

When selecting a knife valve for industrial applications, various key factors must be taken into account to ensure optimal performance and longevity. First and foremost, the media the valve will handle is critical. Knife valves are particularly suited for handling slurries, powders, and viscous fluids, primarily due to their ability to provide a tight seal and effective cut through the material. According to recent industry reports, approximately 70% of knife valve failures can be traced back to compatibility issues, thus emphasizing the importance of choosing a valve material that can withstand the specific corrosive or abrasive characteristics of the media.

Another vital consideration is the size and pressure rating of the valve. It is essential to choose a knife valve that matches the pipeline specifications to prevent leaks and maintain optimum flow rates. Data suggests that improper sizing can result in a 25% decrease in efficiency, leading to increased operational costs. Additionally, the application environment, including temperature and pressure fluctuations, should inform the selection process. Recent surveys indicate that 65% of maintenance issues arise from inadequate pressure ratings or exposure to unanticipated temperature extremes. Selecting a knife valve that can withstand these conditions is imperative for enhancing performance and reducing downtime in processing applications.

Different Types of Knife Valves and Their Uses

Knife valves are a crucial component in various industrial applications, designed primarily for on-off control and isolation of fluid flow. There are several different types of knife valves, each suited for specific operational requirements. The most common types include manual knife valves, powered knife valves, and segmented knife valves. Manual knife valves are operated by hand, making them ideal for applications where frequent adjustment is not necessary. These valves provide a reliable shut-off in systems handling viscous fluids or solids.

Powered knife valves utilize an actuator mechanism, allowing for automated and precise control over the flow of materials. This design is especially beneficial in systems that require consistent operation, such as chemical processing or wastewater treatment. Segmented knife valves, on the other hand, feature a partially open design, which helps in handling slurries and materials that may clog traditional valves. Their ability to operate effectively in difficult conditions makes segmented knife valves a valuable choice in mining or pulp and paper industries.

When selecting a knife valve, it's essential to consider the characteristics of the materials being processed, the operating environment, and the required level of automation. Understanding the distinctions between these types of knife valves will enable engineers and operators to make informed decisions that enhance operational efficiency and safety.

How to Choose the Right Knife Valve for Your Application Needs

| Type of Knife Valve |

Application |

Advantages |

Considerations |

| Standard Knife Valve |

General industrial applications |

Cost-effective and versatile |

Limited to non-abrasive materials |

| Heavy-Duty Knife Valve |

Heavy-duty processes with high wear |

Robust design for harsh conditions |

Higher initial investment |

| Cryogenic Knife Valve |

Cryogenic applications (e.g., LNG) |

Specially designed for low temperatures |

Needs specific materials to handle low temps |

| Electric Knife Valve |

Automation in process control |

Automated operation and easy integration |

Requires reliable power source |

| Sanitary Knife Valve |

Food and pharmaceutical industries |

Easy to clean and maintain |

Costly compared to standard types |

Materials and Construction for Knife Valve Durability

When selecting a knife valve, the materials and construction play a crucial role in ensuring durability and performance in various applications. Knife valves are designed for on-off services, particularly in handling slurries, viscous fluids, and other challenging materials. Therefore, the choice of materials—such as stainless steel, carbon steel, and plastic—should be dictated by the specific conditions, including temperature, pressure, and the chemical nature of the medium. For instance, stainless steel offers excellent corrosion resistance, making it suitable for harsh environments, while carbon steel may be preferable for high-pressure systems.

In addition to materials, the construction of the knife valve significantly affects its long-term reliability. Features like the design of the blade, sealing mechanisms, and the type of actuators employed are essential considerations. A well-designed blade should ensure smooth operation and minimize wear while maintaining a tight seal when closed. Furthermore, the construction should allow for easy maintenance and replacement of parts, as this can prolong the valve’s lifespan and optimize its performance. Overall, understanding the relationship between materials and construction will aid in making an informed choice that meets the specific demands of any application.

Knife Valve Material Durability Comparison

Maintenance and Installation Tips for Knife Valves

When it comes to the maintenance and installation of knife valves, proper procedures are essential to ensure the longevity and reliability of these critical components.

According to industry standards, routine inspections should be conducted every six months, focusing on the valve's seats and packing for signs of wear or leakage.

A recent report from the Valve Manufacturers Association indicates that 30% of valve failures are due to improper installation, highlighting the importance of adhering to manufacturer specifications during setup.

Incorrect alignment or inadequate torque can lead to premature failure, making a thorough understanding of installation procedures vital.

In addition to careful installation, regular maintenance is crucial to achieving optimal performance from knife valves.

Lubrication of the stem and packing can significantly enhance operation, reducing friction and wear.

The American Petroleum Institute recommends a proactive maintenance schedule, which includes inspecting actuator components and testing for proper function weekly in high-usage environments.

Furthermore, ensuring that the valve is operated within its specified pressure and temperature ratings can help prevent damage and extend its service life.

Implementing these best practices will not only minimize downtime but also contribute to a more efficient and cost-effective operation in various industrial applications.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.