7 Compelling Reasons to Choose the Best Wafer Butterfly Valve for Your Project

In the rapidly evolving landscape of industrial applications, the selection of components such as the

wafer butterfly valve can significantly impact project outcomes.

According to a recent report by MarketsandMarkets, the global butterfly valve market is projected to grow

from $3.5 billion in 2020 to $4.8 billion by 2025, reflecting a

compound annual growth rate (CAGR) of 6.3%. This growth underscores the increasing demand

for efficient, reliable, and cost-effective valve solutions in various sectors including

water treatment, oil and gas,

and chemical processing. However, choosing the best wafer

butterfly valve for your project involves more than just understanding market trends; it requires a

meticulous approach to sourcing from reputable suppliers.

This blog will explore seven compelling reasons to opt for high-quality wafer butterfly valves and

provide a comprehensive checklist to guide you in identifying top-tier suppliers, ensuring

that your project meets operational standards and regulatory requirements.

Understanding Wafer Butterfly Valve Standards in Industry

Understanding the standards of wafer butterfly valves in the industry is crucial for ensuring reliability and performance in various applications. Recent studies have highlighted the mechanical shock resistance of butterfly valves, particularly those designed for the naval defense sector. This aspect is increasingly important as industries seek to improve the durability and functionality of these valves under intense conditions. The global industrial valves market, valued at USD 135.85 billion in 2022, is projected to grow at a CAGR of 5.4% from 2023 onwards, reflecting the rising demand for high-performance components like butterfly valves in diverse sectors.

Tips: When selecting a wafer butterfly valve, consider the material composition to enhance shock resistance and longevity. Additionally, pay attention to the valve’s specifications to ensure compliance with industry standards and operational requirements.

It's also noteworthy that the butterfly valve market is expected to reach USD 11.3 billion by 2024, with a CAGR of 5% anticipated through 2034. Factors driving this growth include advancements in manufacturing technologies and an increasing focus on optimizing valve performance. Industries must not only choose valves that meet standard specifications but also align with modern innovations to ensure efficiency in their operations.

Tips: Regularly consult industry reports and case studies to stay informed about the latest trends and technologies in valve manufacturing. Prioritize suppliers that demonstrate a commitment to quality and innovation for your projects.

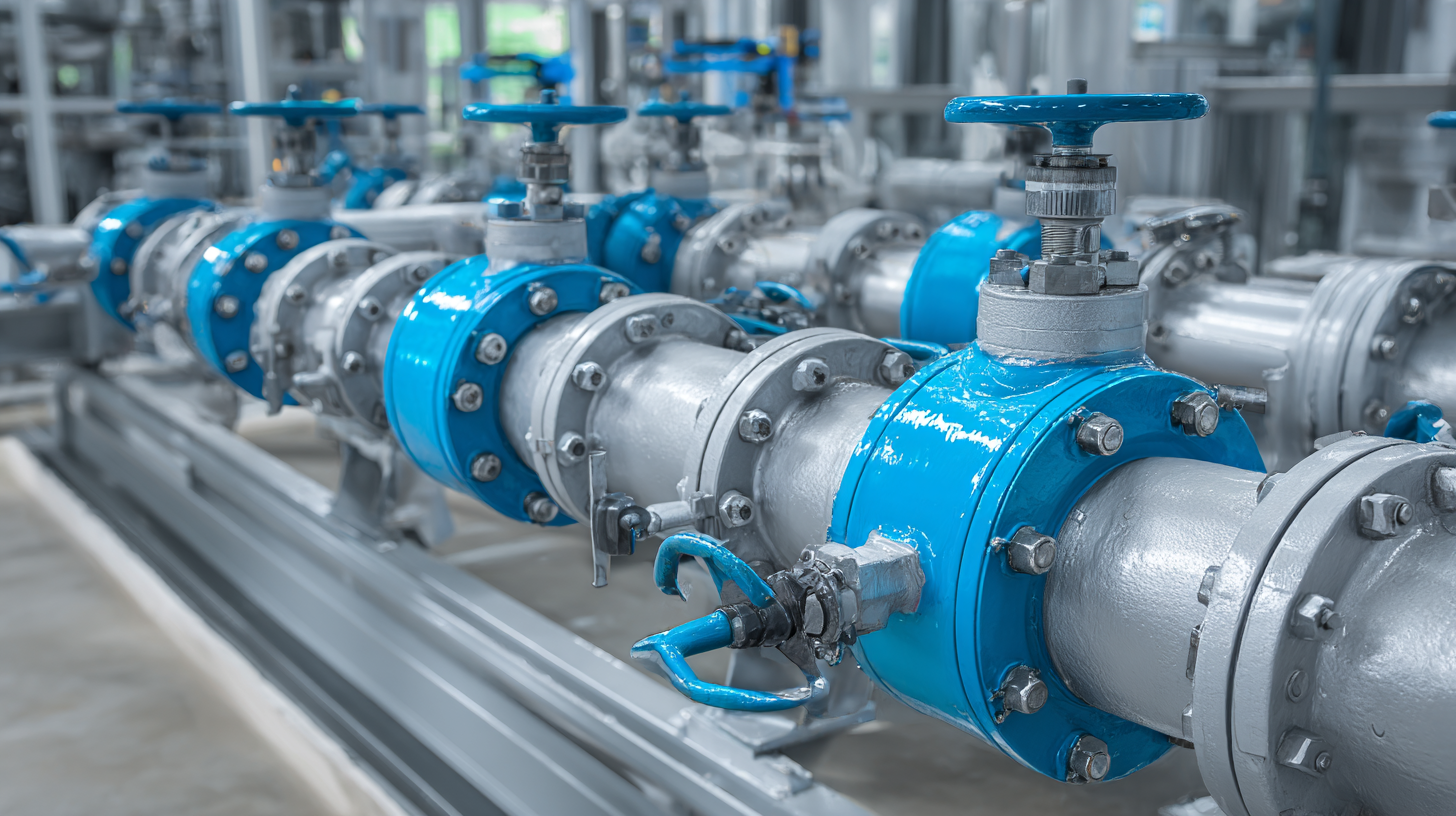

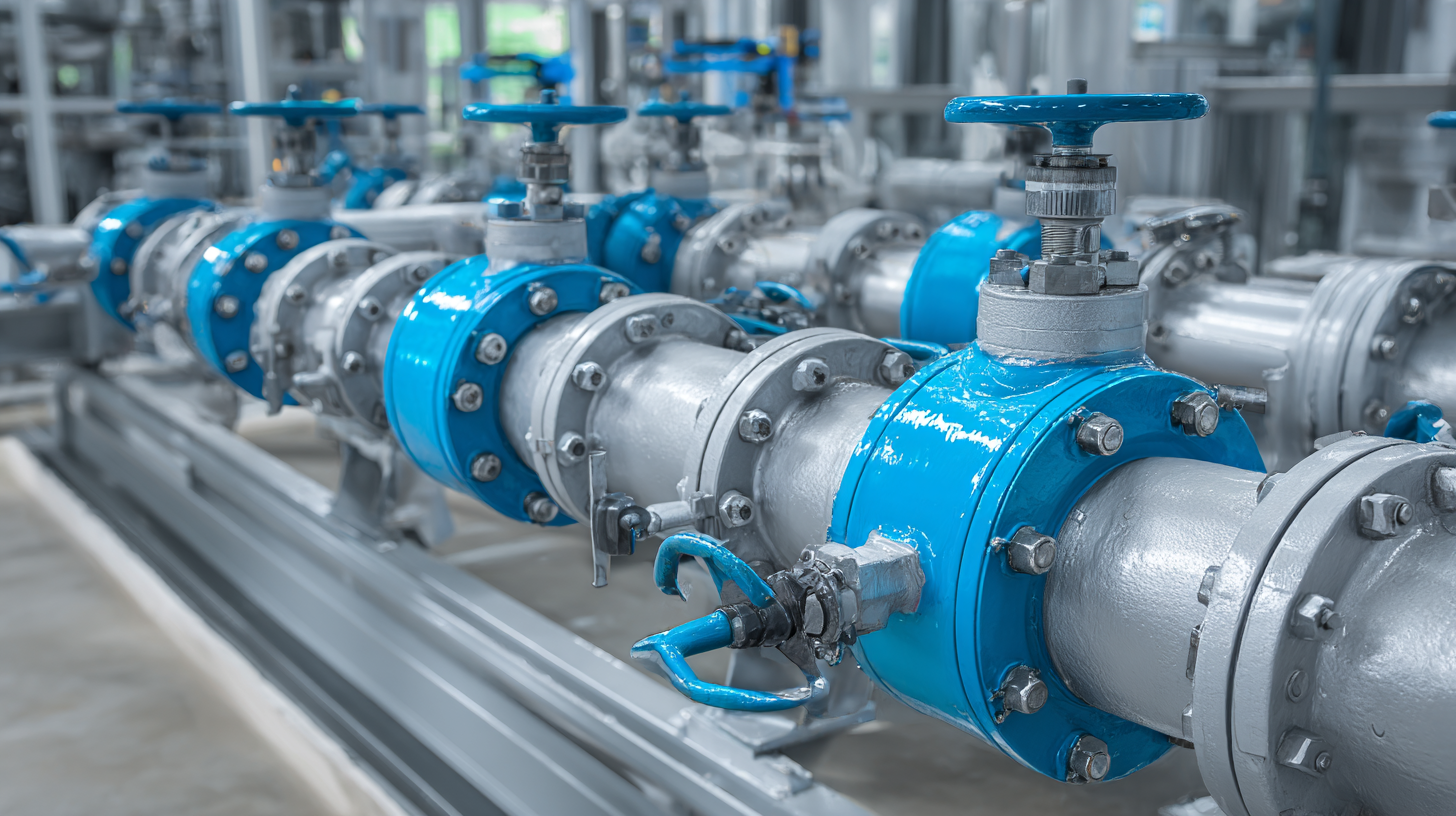

Key Benefits of Wafer Butterfly Valves for Various Applications

Wafer butterfly valves are increasingly recognized for their versatility and efficiency in various industrial applications. According to a report by the Global Valve Market, the demand for wafer butterfly valves is projected to grow at a CAGR of 5.6% from 2021 to 2027, driven largely by their compact design and ease of installation. Unlike traditional gate valves, wafer butterfly valves offer substantial weight savings and require less space, making them an ideal choice for both new systems and retrofitting projects.

In addition to their space-saving attributes, wafer butterfly valves are advantageous in applications where flow regulation is critical. The American Society of Mechanical Engineers (ASME) highlights that the valve’s quick on/off functionality can lead to energy savings of up to 20% in fluid handling systems. This efficiency is particularly advantageous in sectors such as water treatment, HVAC, and food processing, where optimal flow control directly impacts operational costs and system performance. The growing emphasis on sustainability further reinforces the selection of wafer butterfly valves, as they contribute to reduced energy consumption and lower emissions in various industrial processes.

7 Compelling Reasons to Choose Wafer Butterfly Valves

This chart illustrates the key benefits of wafer butterfly valves across various applications, highlighting attributes such as Cost Efficiency, Space Savings, Flow Control, Easy Maintenance, Versatility, Lightweight, and Corrosion Resistance.

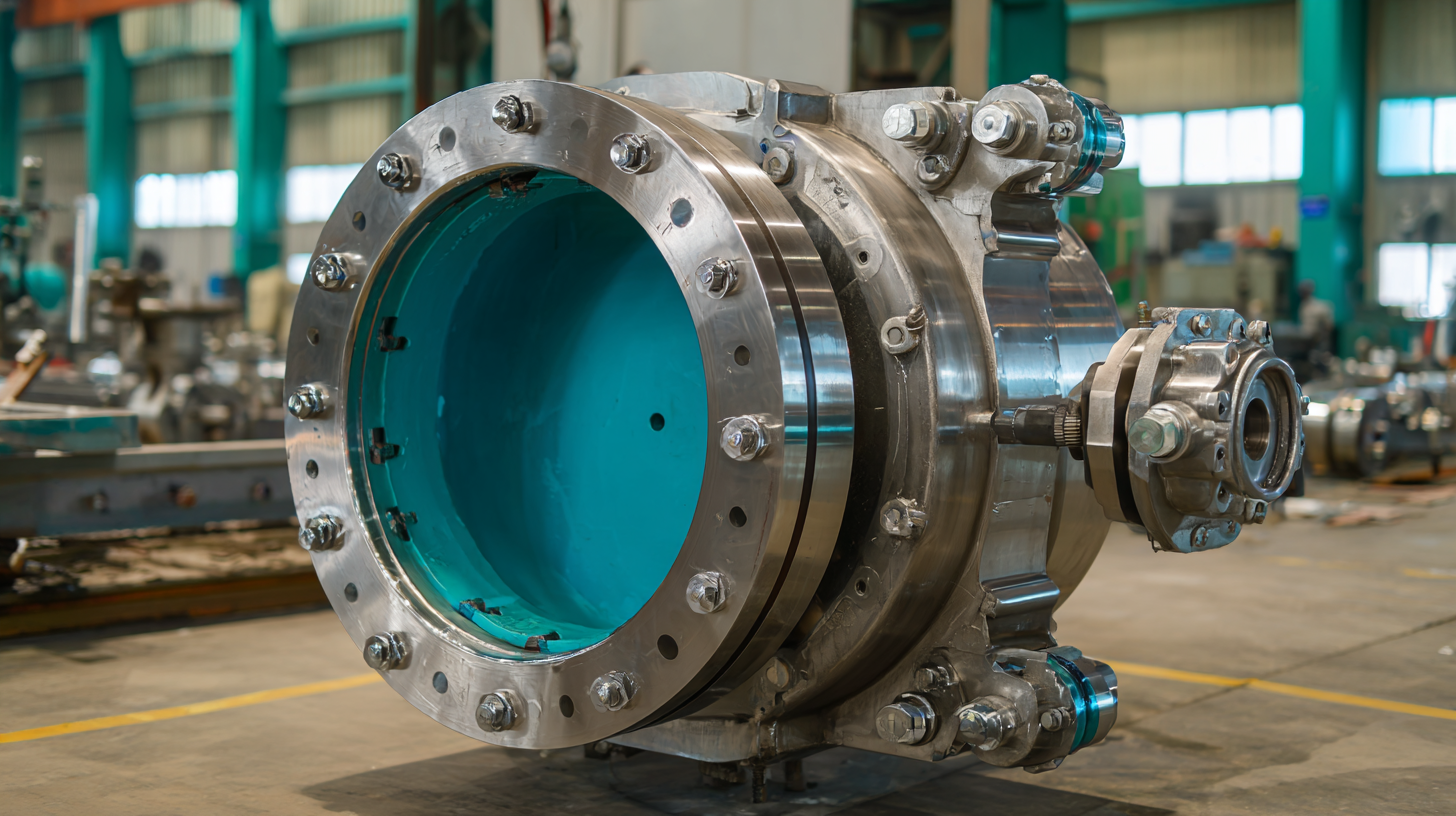

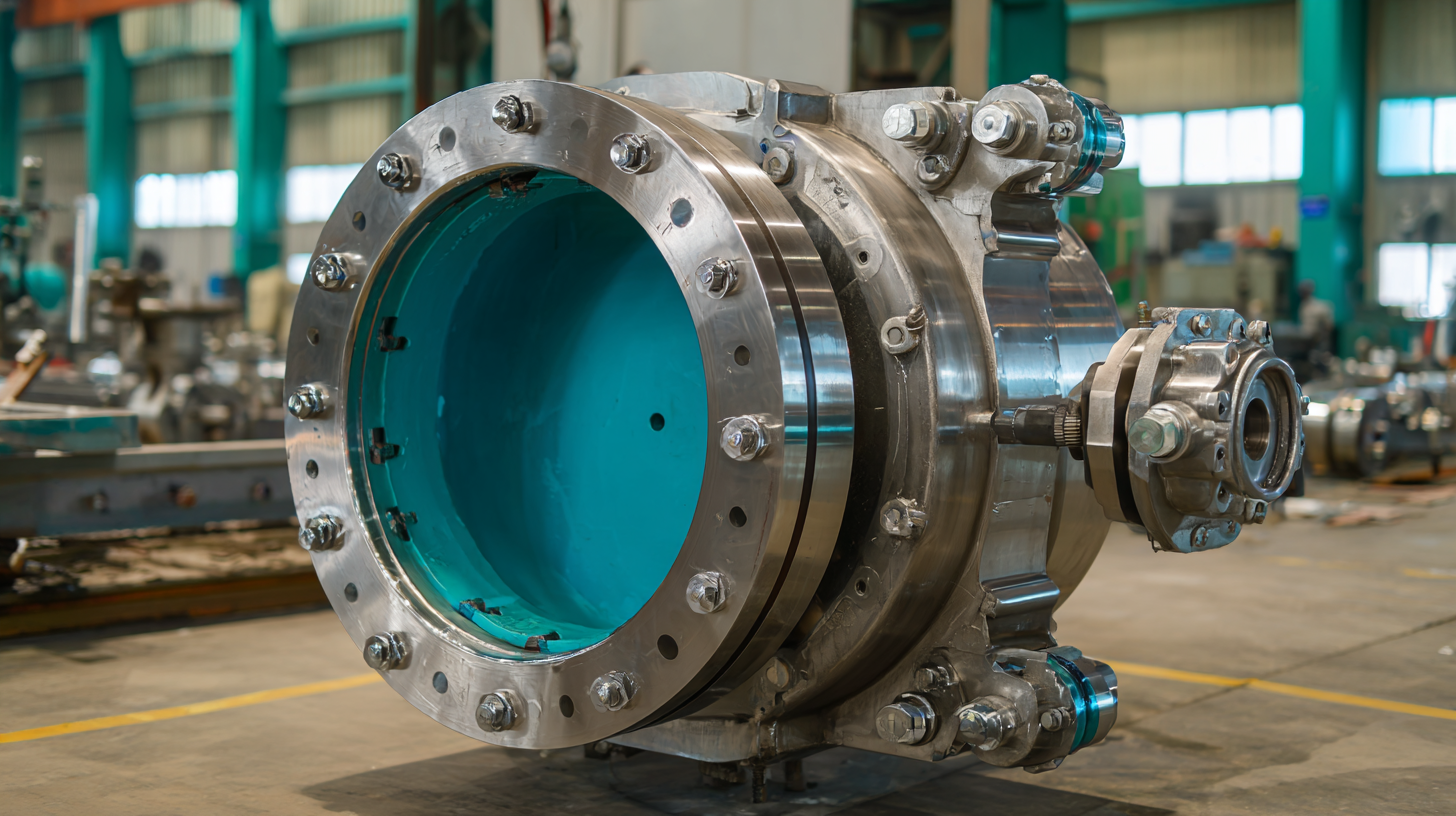

Essential Factors to Consider When Choosing a Wafer Butterfly Valve

When selecting a wafer butterfly valve for your project, several essential factors must be considered to ensure optimal performance and reliability. The global butterfly valve market is set to reach USD 22.1 billion by 2035, growing at a compound annual growth rate (CAGR) of 6.5%. This impressive growth highlights the increasing demand for efficient and innovative valve solutions across various industries. Choosing a valve that meets your specific needs can significantly impact your project's success.

One pivotal aspect to consider is the valve's design and suitability for your application. For instance, advancements in mechanical shock resistance have been made, particularly for valves used in demanding environments like the naval defense sector. Evaluating the mechanical shock behavior of valves can be crucial for ensuring long-term durability and reliability. Additionally, newer models feature improved installation efficiency and performance attributes, which can streamline project timelines and reduce overall costs. Selecting a high-quality valve not only enhances operational integrity but also aligns with industry trends towards sustainability and cost-effectiveness.

Installation Tips for Optimal Performance of Wafer Butterfly Valves

When installing wafer butterfly valves, proper techniques are essential for ensuring optimal performance. First and foremost, ensure that the valve is positioned correctly between the flanges, allowing for seamless integration into the piping system. It’s crucial to align the valve properly to avoid undue stress on the valve body, which could compromise its integrity and functionality. Utilize flange gaskets to prevent leaks, and be sure to tighten bolts in a crisscross pattern to ensure even distribution of pressure.

Another important aspect of the installation process is to consider the surrounding environment and operational conditions. For high-temperature applications, use materials that can withstand thermal expansion without affecting the valve’s performance. Additionally, allow for sufficient spacing around the valve for maintenance access and ensure that there’s proper drainage to prevent fluid accumulation. Following these tips will not only enhance the efficiency of the wafer butterfly valve but also extend its lifespan, contributing to the overall success of your project.

7 Compelling Reasons to Choose the Best Wafer Butterfly Valve for Your Project - Installation Tips for Optimal Performance of Wafer Butterfly Valves

| Reason |

Description |

Installation Tips |

| Compact Design |

Wafer butterfly valves are lightweight and take up less space. |

Ensure an even surface for a smooth installation. |

| Cost-effective |

They offer lower material costs compared to other valve types. |

Consider bulk purchasing for additional savings. |

| Versatility |

Suitable for various applications, including water and gas. |

Verify compatibility with the intended medium. |

| Low Maintenance |

Requires minimal maintenance due to simple design. |

Regularly check for leaks to ensure longevity. |

| Quick Installation |

Installation process is straightforward and fast. |

Follow manufacturer guidelines closely to avoid issues. |

| Minimal Pressure Drop |

Offers excellent flow characteristics with minimal pressure loss. |

Choose the right size valve for the application. |

| Durability |

Built to withstand high pressures and temperatures. |

Regularly inspect for wear and tear, especially in harsh environments. |

Maintaining Quality: Best Practices for Wafer Butterfly Valve Selection

When selecting wafer butterfly valves for your project, maintaining quality is paramount. These valves play a crucial role in numerous applications, and choosing the right one can significantly influence system efficiency and performance. To ensure you make a well-informed decision, consider the following best practices.

First, assess the material compatibility of the valve with the fluid it will be handling. Opt for materials that resist corrosion and wear under specific operating conditions. This will not only extend the lifespan of the valve but also minimize maintenance costs. Tip: Always check the manufacturer's specifications for temperature and pressure ratings to ensure seamless integration with your system.

Next, evaluate the design and construction of the valve. A well-designed wafer butterfly valve should provide smooth operation and reliable sealing. Ensure that the valve has been tested for durability and performance under various conditions.

Tip: Consult with experienced engineers or suppliers who can provide insight into the best valve designs for your specific applications. This expert advice can help you avoid common pitfalls and ensure a successful project outcome.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.