The Essential Guide to Understanding Air Check Valves in Modern Plumbing Systems

In modern plumbing systems, the air check valve plays a crucial role in maintaining system efficiency and preventing backflow, a significant concern in water distribution and waste management. According to industry analysis by the Plumbing Manufacturers International, improper plumbing practices can lead to substantial water losses, estimated at over 1 trillion gallons annually in the United States alone. Air check valves are essential components designed to address this issue by allowing air to escape from the system while preventing water from reversing direction. Furthermore, a report from the American Society of Plumbing Engineers highlights that the integration of air check valves can enhance system performance and longevity, reducing the need for costly repairs and maintenance. With the increasing complexity of plumbing systems and growing environmental concerns, understanding the pivotal function of air check valves is more important than ever for both professionals and homeowners alike.

Key Functions of Air Check Valves in Plumbing Systems

Air check valves play a crucial role in modern plumbing systems, ensuring the safe and efficient movement of liquids. These devices primarily prevent backflow, which can lead to contamination of potable water sources. According to the American Society of Plumbing Engineers (ASPE), nearly 70% of plumbing failures can be attributed to improper backflow prevention. By installing air check valves, plumbers can mitigate these risks, safeguarding public health and maintaining system integrity.

In addition to preventing backflow, air check valves help to maintain the necessary air pressure within pipelines. This is vital for minimizing water hammer effects, which can cause significant damage to plumbing fixtures and infrastructure. A study from the Plumbing Manufacturers International (PMI) indicates that proper air pressure regulation can extend the lifespan of plumbing systems by up to 30%. Thus, integrating air check valves within a plumbing design is essential not just for compliance but for long-term sustainability.

**Tip 1:** Regularly inspect and replace air check valves every 5 years to ensure optimal performance and prevent water quality issues.

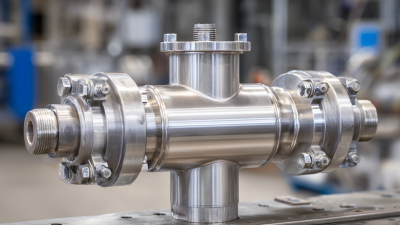

**Tip 2:** Consider using stainless steel or high-quality plastic air check valves for enhanced durability, especially in high-pressure systems.

The Essential Guide to Understanding Air Check Valves in Modern Plumbing Systems

| Function |

Description |

Material |

Common Applications |

| Prevent Backflow |

Stops the reverse flow of fluids in a plumbing system, ensuring safe and efficient operation. |

PVC, Brass, Stainless Steel |

Residential plumbing, Irrigation systems |

| Pressure Stabilization |

Helps maintain consistent pressure levels within the system to avoid fluctuations. |

Brass, Cast Iron |

Commercial buildings, Industrial systems |

| Noise Reduction |

Minimizes the noise caused by sudden changes in water flow or pressure. |

Plastic, Rubber |

Residential plumbing, High-rise buildings |

| Protection from Contaminants |

Prevents contaminated water from entering the clean water supply. |

Copper, Plastic |

Water treatment facilities, Municipal water supply |

Types of Air Check Valves: Choosing the Right One for Your Needs

When selecting the right air check valve for your plumbing system, it's crucial to understand the different types available. Air check valves primarily fall into two categories: spring-loaded and diaphragm types. According to a recent report by the American Society of Plumbing Engineers (ASPE), spring-loaded valves are often preferred in residential systems for their reliability and simplicity. They allow for backflow prevention and ensure consistent air pressure, making them ideal for typical household plumbing.

On the other hand, diaphragm valves are often used in industrial applications due to their precise control and ability to handle varying pressure levels. A study by the Plumbing Manufacturers International (PMI) indicated that diaphragm valves can significantly reduce the risk of water hammer and pressure fluctuations, which are common issues in larger systems. This makes them a favorable choice for high-demand environments.

**Tips:** When choosing an air check valve, consider the specific requirements of your plumbing system, including flow rates and pressure conditions. Always consult manufacturer specifications to ensure compatibility. Additionally, regularly inspecting and maintaining your check valves can prevent costly repairs and system failures.

The Essential Guide to Understanding Air Check Valves in Modern Plumbing Systems

Installation Tips for Air Check Valves to Ensure Optimal Performance

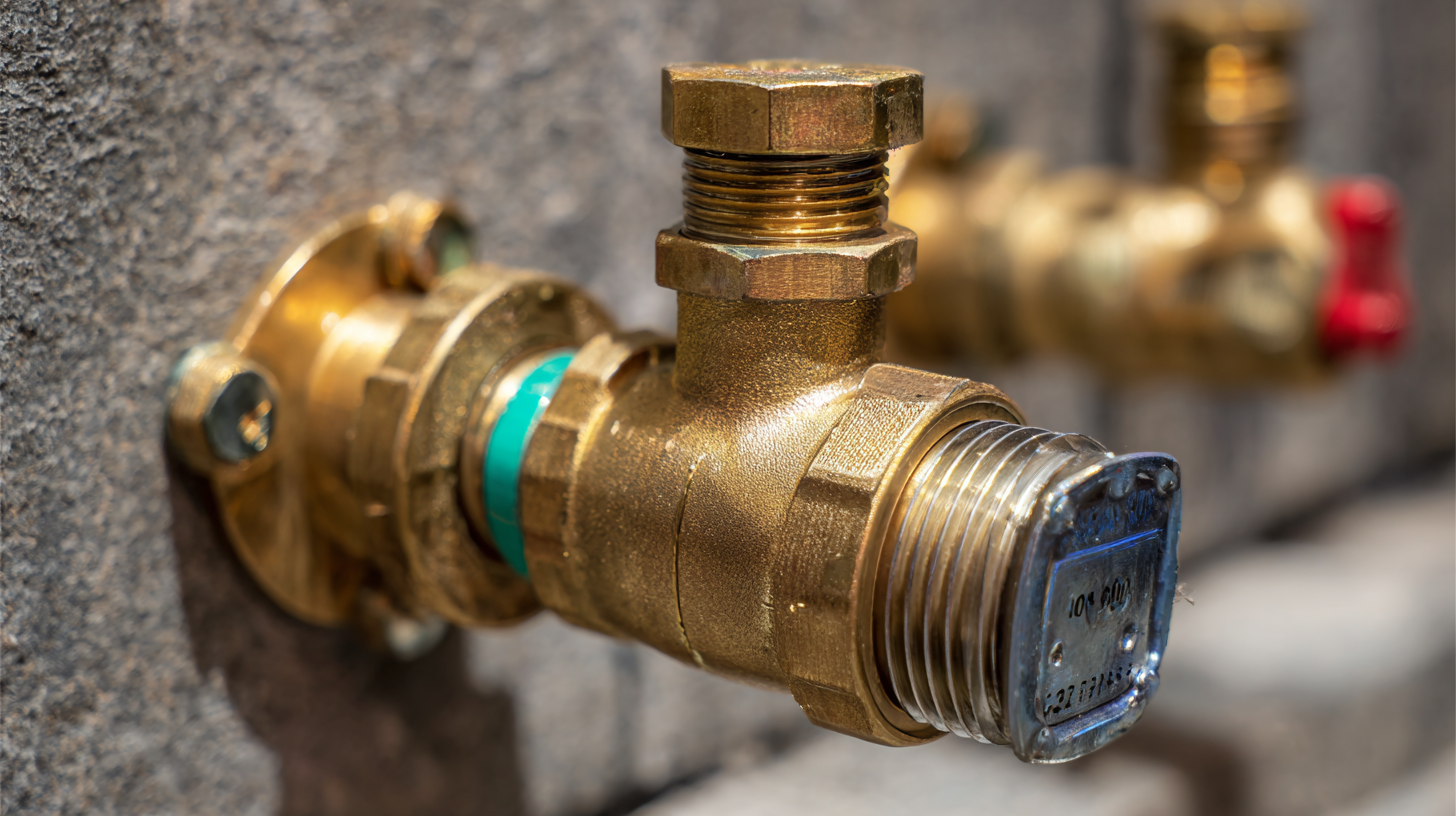

When installing air check valves in modern plumbing systems, proper placement is crucial for optimal performance. These valves are designed to prevent backflow and maintain air pressure in the system, ensuring efficient operation. Begin by identifying the best location for the valve, typically positioned near pipelines that are subject to varying pressures. It is essential to follow manufacturer guidelines regarding orientation, as correct placement will enhance the valve's effectiveness and longevity.

When installing air check valves in modern plumbing systems, proper placement is crucial for optimal performance. These valves are designed to prevent backflow and maintain air pressure in the system, ensuring efficient operation. Begin by identifying the best location for the valve, typically positioned near pipelines that are subject to varying pressures. It is essential to follow manufacturer guidelines regarding orientation, as correct placement will enhance the valve's effectiveness and longevity.

Before installation, ensure all necessary tools and materials are at hand. Clean the pipe ends to remove any debris or contaminants, and consider using Teflon tape on the threads to promote a tight seal. When securing the valve, avoid over-tightening, which can damage the valve and compromise its function. After installation, monitor the system for leaks and ensure the valve operates smoothly during routine use. Regular maintenance checks can help detect potential issues early on, safeguarding the plumbing system against malfunctions related to air pressure fluctuations.

Common Issues with Air Check Valves and How to Troubleshoot Them

Air check valves are crucial components in modern plumbing systems, ensuring that water flows in the correct direction and preventing backflow. Common issues often arise with these valves, which can lead to inefficiencies and potential damage. One prevalent problem is the valve sticking due to debris accumulation or corrosion. This can hinder the valve's ability to close properly, allowing unwanted reverse flow.

Regular inspection and maintenance are vital, as removing contaminants and applying a suitable lubricant can restore functionality.

Air check valves are crucial components in modern plumbing systems, ensuring that water flows in the correct direction and preventing backflow. Common issues often arise with these valves, which can lead to inefficiencies and potential damage. One prevalent problem is the valve sticking due to debris accumulation or corrosion. This can hinder the valve's ability to close properly, allowing unwanted reverse flow.

Regular inspection and maintenance are vital, as removing contaminants and applying a suitable lubricant can restore functionality.

Another frequent issue is valve failure due to pressure fluctuations. These fluctuations can cause damage to the valve seat, leading to leaks. To troubleshoot this, checking the system for pressure consistency is essential. If pressure spikes are detected, installing a pressure regulator may help stabilize the system, thus prolonging the lifespan of the air check valves. Additionally, keeping an eye on gasket integrity can prevent potential leaks, ensuring that the plumbing system operates efficiently. Proper installation and periodic checks can significantly mitigate these common issues, enhancing the reliability of air check valves in your plumbing infrastructure.

Maintenance Practices for Longevity of Air Check Valves in Plumbing Systems

Air check valves, an essential component in modern plumbing systems, play a crucial role in preventing backflow and maintaining system integrity. To ensure their longevity, proper maintenance practices must be implemented. Industry reports indicate that nearly 30% of plumbing system failures are attributed to malfunctioning air check valves, underscoring the importance of regular inspections and upkeep.

Routine maintenance should include regular visual inspections for wear and tear, leaks, or corrosion. As outlined in the American Society of Plumbing Engineers (ASPE) guidelines, valves should be cleaned and tested annually to confirm their function. Additionally, replacing any worn parts promptly can significantly extend the service life of these valves, often by 50% or more, according to a study published in the Journal of Plumbing and Mechanical Engineering. Implementing these maintenance practices not only enhances the efficiency of plumbing systems but also mitigates costly repairs and system downtimes caused by neglected air check valves.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

When installing air check valves in modern plumbing systems, proper placement is crucial for optimal performance. These valves are designed to prevent backflow and maintain air pressure in the system, ensuring efficient operation. Begin by identifying the best location for the valve, typically positioned near pipelines that are subject to varying pressures. It is essential to follow manufacturer guidelines regarding orientation, as correct placement will enhance the valve's effectiveness and longevity.

When installing air check valves in modern plumbing systems, proper placement is crucial for optimal performance. These valves are designed to prevent backflow and maintain air pressure in the system, ensuring efficient operation. Begin by identifying the best location for the valve, typically positioned near pipelines that are subject to varying pressures. It is essential to follow manufacturer guidelines regarding orientation, as correct placement will enhance the valve's effectiveness and longevity.