Top 10 Essential Tips for Choosing the Right Swing Check Valve

Choosing the right swing check valve is crucial for ensuring the efficient operation of fluid systems in various industries. According to industry expert Dr. Emily Carter, a renowned mechanical engineer with over 15 years of experience in valve technology, "A properly selected swing check valve can greatly enhance system reliability and performance." Understanding the key factors involved in this selection process is essential for engineers and procurement professionals alike.

As we delve into the top ten essential tips for choosing a swing check valve, it is important to consider aspects such as material compatibility, pressure rating, and flow direction. Each of these factors can significantly influence the valve's effectiveness and longevity. Additionally, recognizing the specific needs of your application will help prevent costly mistakes and enhance overall system functionality. With these insightful tips, you can make informed decisions that lead to successful fluid management solutions.

Understanding Swing Check Valve Functionality and Applications

Swing check valves play a crucial role in various applications by preventing backflow in pipelines while allowing forward flow. The functionality of these valves hinges on a disc that pivots on a hinge, opening when the fluid flows in the desired direction and closing when the flow reverses. This design makes them particularly effective in systems where gravity or pressure is employed to maintain forward flow. Common applications range from water supply systems to wastewater treatment facilities, where controlling flow direction is vital.

When choosing the right swing check valve, one important tip is to consider the size and connection type that corresponds with your pipe system. Ensuring a proper fit will enhance the valve's performance and longevity. Additionally, assessing the material compatibility with the fluids being transported is essential to prevent corrosion and structural degradation.

Another helpful tip is to evaluate the valve's pressure and temperature ratings to ensure that it can withstand the operating conditions of your system. Selecting a valve that meets these specific metrics will enhance reliability and efficiency. Additionally, examining the valve's installation requirements can help streamline the process and reduce potential issues in the long run.

Top 10 Essential Tips for Choosing the Right Swing Check Valve

This chart illustrates the top 10 essential tips for selecting the right swing check valve, based on the importance level of various criteria. A higher score indicates a more crucial factor to consider when making a choice.

Key Material Considerations for Durable Swing Check Valves

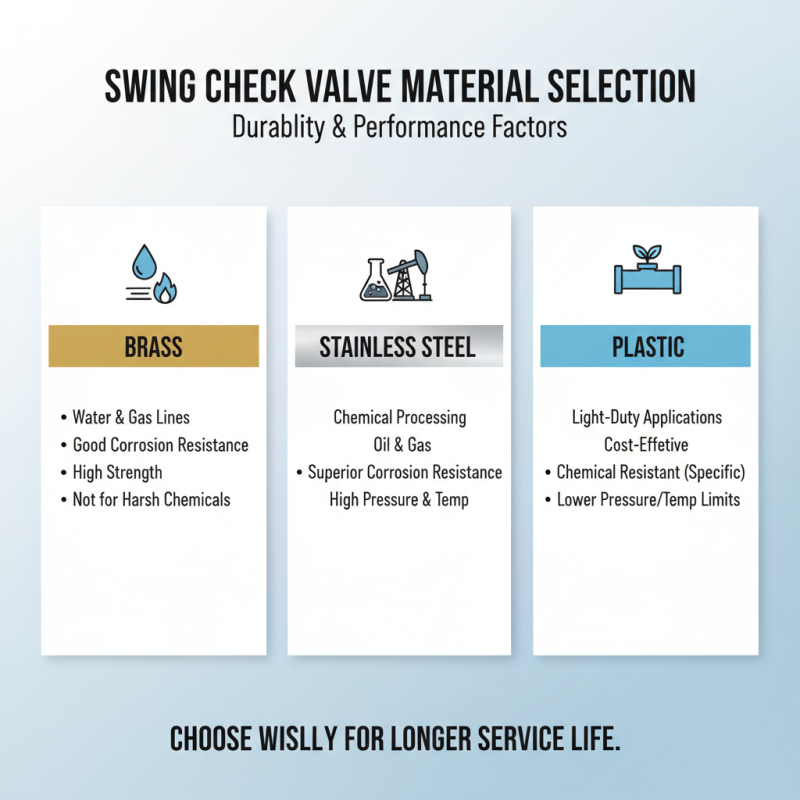

When selecting a swing check valve, material choice is a critical factor influencing its durability and performance. The most commonly used materials for swing check valves include brass, stainless steel, and plastic. Brass valves, known for their excellent corrosion resistance and strength, are ideal for water and gas applications. However, they may not be suitable for highly corrosive environments. On the other hand, stainless steel valves offer superior durability and resilience to harsh chemicals and high-pressure conditions, making them a preferred option in industries such as chemical processing and oil and gas.

Plastic swing check valves, crafted from PVC or PP, serve as lightweight alternatives for less demanding applications. They are often used in drainage systems or irrigation projects due to their resistance to rust and corrosion. However, it's important to consider the specific environment where the valve will be used, as extreme temperatures can affect the material integrity. Ultimately, choosing the right material based on the operational conditions and fluid type will enhance the longevity and reliability of the swing check valve, ensuring optimal functionality in the system.

Sizing and Pressure Ratings: Ensuring Optimal Performance

When choosing a swing check valve, appropriate sizing and understanding pressure ratings are crucial for ensuring optimal performance. Selecting the right valve size means assessing the flow rates and pipe diameter. An oversized valve can lead to inefficient flow, while an undersized one may cause excessive pressure loss. Therefore, it's essential to accurately calculate the flow requirements based on the system's specifications to find a valve that fits snugly within the existing setup.

Pressure ratings are another critical factor in choosing a swing check valve. Valves must be able to withstand the maximum pressure within your system without risking failure. Overlooked pressure considerations can lead to leaks or catastrophic failures, which not only compromise system integrity but can also pose safety hazards. Always refer to the pressure rating specifications to ensure that the valve operates well within its limits, providing longevity and reliable performance.

When making your selection, keep in mind these essential tips: First, consult with a professional to assist in flow calculations. Second, consider the material of the valve for compatibility with the fluids it will handle. Lastly, remember to evaluate the installation environment, as temperature variations can also impact the valve's performance. By focusing on sizing and pressure ratings, you can ensure that your swing check valve delivers the optimal results your system demands.

Top 10 Essential Tips for Choosing the Right Swing Check Valve - Sizing and Pressure Ratings: Ensuring Optimal Performance

| Tip No. |

Tip Description |

Sizing Method |

Pressure Rating (psi) |

| 1 |

Identify the pipe diameter to ensure correct fit. |

Use nominal pipe size standards. |

150 - 300 |

| 2 |

Consider the flow direction to prevent backflow. |

Review system flow diagrams. |

100 - 200 |

| 3 |

Select materials that match fluid characteristics. |

Material compatibility charts. |

200 - 400 |

| 4 |

Check the valve closing speed to avoid water hammer. |

Determine system dynamics. |

150 - 250 |

| 5 |

Evaluate pressure loss through the valve. |

Utilize flow simulation software. |

100 - 300 |

| 6 |

Verify required end connections for installation. |

Refer to connection standards. |

150 - 250 |

| 7 |

Account for temperature effects on valve materials. |

Consult temperature rating guidelines. |

100 - 400 |

| 8 |

Inspect for regulatory compliance (e.g., API, ANSI). |

Review industry standards. |

150 - 300 |

| 9 |

Calculate the total cost of ownership over the valve's lifecycle. |

Perform cost analysis on options. |

N/A |

| 10 |

Choose a reliable supplier with good after-sales support. |

Research supplier credentials. |

N/A |

Evaluating Installation and Maintenance Requirements for Longevity

When selecting a swing check valve, evaluating the installation and maintenance requirements is crucial for ensuring the longevity of the valve and the overall system. Proper installation is the cornerstone of effective operation; valves must be mounted in the correct orientation to prevent backflow and to ensure optimal performance. It is essential to consider the connection types and sizes to seamlessly integrate the valve into existing piping systems.

Additionally, ensuring that the area around the valve allows for adequate space can simplify maintenance tasks in the future.

Maintenance, while often overlooked at the time of valve selection, plays a significant role in extending the lifespan of a swing check valve. It is advisable to choose valves designed for easy access to internal components, such as removable covers or easily replaceable seals. Regular inspections should focus on identifying any signs of wear, corrosion, or fluid leaks. Implementing a routine maintenance schedule not only helps in catching potential issues early but also maximizes the valve’s efficiency and service life.

Common Pitfalls to Avoid When Selecting Swing Check Valves

When selecting swing check valves, it's crucial to be aware of common pitfalls that can lead to inefficient system performance or premature valve failure. One major mistake is neglecting the importance of valve size and flow rates. According to a recent industry report by the Hydraulic Institute, over 30% of system inefficiencies can be traced back to improperly sized valves. An incompatible valve size can cause backflow issues and increase turbulence, ultimately reducing system efficiency and increasing energy costs.

Another common pitfall is overlooking the material composition of the swing check valve. Many engineers focus solely on the initial cost, ignoring how material choice impacts durability and maintenance. A study by the American Water Works Association (AWWA) highlighted that nearly 25% of valve failures are due to corrosion or wear resulting from inappropriate material selection. Ensuring compatibility with the fluid being transported is vital; thus, selecting materials that can withstand the specific environmental conditions and chemical composition of the fluid will enhance longevity and performance.

Additionally, failing to consider installation practices can hinder the effectiveness of swing check valves. The same AWWA report pointed out that improper installation techniques can lead to significant operational issues, including misalignment or undue stress on the valve. Ensuring proper orientation during installation, as indicated by manufacturer guidelines, is essential to avoid costly repairs down the line. By being mindful of these common pitfalls, engineers can make more informed decisions, enhancing both functionality and cost-effectiveness of their systems.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.