Exploring Innovative Alternatives to 3 Way Ball Valves for Global Buyers

In the ever-evolving landscape of industrial fluid control, the 3 way ball valve has been a cornerstone technology, known for its reliability and efficiency. According to a recent market research report by Research and Markets, the global ball valve market is projected to reach USD 9.2 billion by 2026, growing at a CAGR of 5.2% from 2021 to 2026. However, as industries seek to enhance performance and adapt to diverse operational needs, innovative alternatives to 3 way ball valves are gaining traction.

This blog delves into cutting-edge strategies for sourcing these alternatives, catering to global buyers who are eager to optimize fluid handling systems while navigating the complexities of a competitive marketplace. By examining emerging technologies and shifting market demands, we aim to provide insights that empower businesses to make informed decisions in their valve procurement processes.

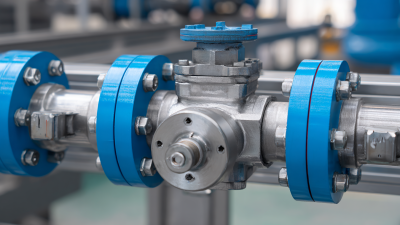

The Limitations of Traditional 3 Way Ball Valves in Modern Applications

In the realm of industrial applications, traditional 3-way ball valves have long been a staple for fluid control. However, their limitations are becoming increasingly evident as industries seek more flexible and efficient solutions. Recent studies indicate that 3-way ball valves can introduce flow restrictions, especially in high-demand scenarios, where dynamic flow control is essential. For instance, research from the Flow Control Association highlights that traditional designs can experience pressure drops exceeding 20% in certain configurations, leading to inefficiencies and increased operational costs.

As global buyers explore

innovative alternatives, technologies such as rotary plug valves and multi-port valve solutions are gaining traction. These alternatives not only provide

superior control with reduced pressure loss — achieving up to

10% efficiency gains compared to conventional ball valves — but also offer enhanced versatility in complex piping systems. This evolution reflects a growing trend in industries striving for

sustainability and operational excellence, where the adoption of more advanced valve systems can significantly reduce waste and improve energy efficiency.

Moreover, as industries worldwide embrace the

digital transformation, integrating smart valves with IoT capabilities has commenced, allowing for real-time monitoring and data analytics. This shift not only helps in eliminating manual errors but also ensures

optimal performance under varying operational conditions. The rise of these innovative alternatives marks a significant evolution in the market, meeting the demands of modern applications while overcoming the limitations imposed by traditional designs.

Emerging Technologies: Smart Valves and Their Impact on Efficiency

The landscape of valve technology is experiencing a transformative shift, particularly with the emergence of smart valves that leverage cutting-edge innovations. According to a recent report by MarketsandMarkets, the smart valve market is projected to reach $4.5 billion by 2026, growing at a CAGR of 10.2% from 2021. This surge can be attributed to the increasing demand for automation and the need for enhanced operational efficiency across various industries, including oil and gas, water management, and manufacturing.

Smart valves are equipped with advanced monitoring and control systems that enable real-time data communication and feedback. This capability not only streamlines workflow processes but also contributes to significant energy savings and reduced operational costs. A study conducted by the International Journal of Engineering Research & Technology found that implementing smart valve technologies could enhance system efficiency by up to 30%, showcasing their potential to revolutionize fluid control applications. As global buyers look to adopt innovative solutions, the integration of smart valves represents a pivotal step towards achieving higher productivity and sustainability in their operations.

Exploring Innovative Alternatives to 3 Way Ball Valves for Global Buyers - Emerging Technologies: Smart Valves and Their Impact on Efficiency

| Technology |

Efficiency Improvement (%) |

Application |

Advantages |

Challenges |

| Smart Pressure Control Valves |

20% |

Oil & Gas |

Reduced energy consumption, real-time monitoring |

High initial costs |

| Electro-Pneumatic Actuated Valves |

15% |

Chemical Processing |

Precision control, faster response |

Complex integration |

| Wireless Smart Valves |

30% |

Water Management |

Remote monitoring, reduced leakage |

Battery life concerns |

| Digital Flow Control Valves |

25% |

HVAC Systems |

Increased comfort, adaptive performance |

Software maintenance |

| Autonomous Valves |

35% |

Renewable Energy |

Self-regulating, minimal human intervention |

Technological reliability |

Cost-Effective Alternatives: Exploring Globe and Diaphragm Valves

As global industries strive for cost efficiency, the demand for cost-effective alternatives to traditional three-way ball valves has surged. Among these, globe valves and diaphragm valves are gaining traction due to their unique properties and advantages. According to a recent report by MarketsandMarkets, the global valve market is projected to reach USD 90.5 billion by 2027, with a significant contribution from globe and diaphragm valves, driven by their efficiency in flow regulation and pressure control.

Globe valves are particularly renowned for their capability to provide precise flow control, making them indispensable in applications requiring tight regulation, such as in the oil and gas sector. A report from Valves and Actuators Market Research indicates that globe valves are preferred in various sectors, with a market share expected to rise by over 20% in the next five years. On the other hand, diaphragm valves are favored in sanitary and corrosive applications due to their simple design and ease of maintenance. The same research points out that diaphragm valves are increasingly utilized in the pharmaceutical and food industries, driven by stringent regulations for material safety and process hygiene.

Both globe and diaphragm valves not only offer viable alternatives to three-way ball valves but also provide enhanced operational efficiency and lower long-term costs. As industries worldwide continue to prioritize sustainability and economic viability, adopting these valve types could lead to significant savings and improved performance.

Sustainability in Valve Design: Eco-Friendly Innovations for Buyers

In recent years, the focus on sustainability has significantly influenced valve design, pushing manufacturers to innovate and adopt eco-friendly practices. Buyers are now seeking alternatives to traditional 3-way ball valves that align with environmentally responsible principles. One of the exciting developments in this field is the use of biodegradable materials in valve construction. These materials not only reduce the environmental impact during production but also offer efficient performance, serving the dual purpose of durability and sustainability.

Additionally, manufacturers are optimizing designs to minimize waste and energy consumption associated with valve operation. By exploring innovative alternatives like smart valves equipped with sensors for real-time monitoring, buyers can enhance efficiency while contributing to energy savings. Such advancements not only improve system performance but also reflect an overall commitment to greener industrial practices. As global buyers continue to prioritize sustainability, the valve industry is poised to embrace these eco-friendly innovations, setting new standards for responsible manufacturing and environmental stewardship.

Global Market Trends: Differentiating Between Valve Types and Their Uses

In the evolving landscape of the global valve market, understanding the diverse types and their specific applications is crucial for buyers, especially when exploring alternatives to widely used 3-way ball valves. The cryogenic valve segment, which focuses on controlling the flow of cryogenic fluids, is witnessing significant expansion. With its market size valued at $4.14 billion in 2023, projections indicate a remarkable growth trajectory, reaching approximately $9.73 billion by 2032. Such growth underscores the increasing demand for specialized valves tailored for environments dealing with extremely low temperatures.

Differentiating between valve types not only aids in selecting the right equipment but also aligns with the shifting trends towards sustainable and efficient solutions in various industries. For instance, while traditional ball valves are popular for their simplicity and reliability, alternative valve technologies offer unique benefits that may better suit specific applications. As global buyers seek to optimize their supply chains, understanding these nuances becomes imperative for making informed and strategic decisions in an increasingly competitive market.

Exploring Innovative Alternatives to 3 Way Ball Valves

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.