Understanding the Functionality of Knife Gate Valves in Industrial Applications

In industrial applications, the choice of valves plays a crucial role in optimizing operations and ensuring system reliability. Among various types of valves, the knife gate valve has emerged as a popular solution due to its robust design and efficiency in handling bulk materials. According to a report by MarketsandMarkets, the global valve market is projected to reach $101.8 billion by 2025, with significant growth anticipated in the water and wastewater industry, where knife gate valves are extensively utilized for their ability to provide tight sealing and minimal leakage. Their versatility makes them suitable for various applications, including pulp and paper, mining, and petrochemical sectors. Understanding the functionality of knife gate valves, including their design features and operational benefits, is essential for engineers and industrial operators seeking to enhance process performance and reduce maintenance costs in their systems.

Types of Knife Gate Valves and Their Unique Features

Knife gate valves are essential components in various industrial applications, particularly in handling slurries, powders, and granulated materials. The design of these valves is optimized for minimal pressure drop and reliable sealing, which makes them ideal for industries such as mining, wastewater treatment, and food processing. According to a recent report by Grand View Research, the global knife gate valve market is expected to witness substantial growth, projected to reach USD 1.45 billion by 2025, driven by the increasing demand for efficient fluid control systems.

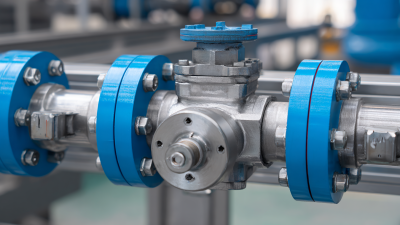

There are several types of knife gate valves, each with unique features tailored to specific applications. For instance, the unidirectional valve is designed for flow in one direction, making it suitable for handling thick fluids with solids, while the bi-directional knife gate valve allows for flow in both directions, providing versatility in pipeline systems. Additionally, high-performance knife gate valves, equipped with enhanced sealing technology, can withstand extreme pressure and temperature conditions, making them invaluable in process industries. The differentiated capabilities of these valves contribute significantly to operational efficiency, thus enhancing overall productivity in industrial settings.

Key Applications of Knife Gate Valves in Various Industries

Knife gate valves are pivotal in a range of industrial applications, particularly where the handling of fluids and solids is involved. These valves excel in environments requiring the cutting through thick materials, such as pulp and paper, wastewater treatment, and mining operations. Their design allows for a tight seal during operation, minimizing leakage and providing reliable flow control. The ability to effectively manage flow with minimal pressure drop makes knife gate valves indispensable in systems where efficiency is paramount.

Moreover, the global market for double block and bleed valves, which share similar applications in fluid control systems, is projected to reach USD 450 million by 2024, with an anticipated growth to USD 5.9 billion by 2033, marking a compound annual growth rate of 3%. This growth mirrors the expanding role of efficient valve technologies across various sectors, including oil and gas, chemicals, and water management. As industries continue to evolve and seek enhanced operational efficiencies, the demand for advanced valve solutions, such as knife gate valves, is likely to increase, underscoring their significance in modern industrial applications.

Advantages of Using Knife Gate Valves in Fluid Control Systems

Knife gate valves are increasingly popular in fluid control systems due to their unique design and operational advantages. These valves are engineered to provide a reliable and efficient solution for managing the flow of various fluids, particularly in industrial settings. One of the primary benefits of knife gate valves is their ability to handle thick and viscous materials, making them ideal for applications in wastewater treatment, mining, and pulp and paper industries. The blade-like gate effectively shears through slurries and solids, preventing clogging and ensuring uninterrupted flow.

Another significant advantage of knife gate valves is their simplicity in design, which translates to lower maintenance costs and increased reliability. The minimal number of moving parts not only reduces the likelihood of mechanical failure but also allows for easy operation, whether manual or automated. Additionally, the ability to create a tight seal when closed ensures that there are no leaks, further enhancing the control over fluid movement. This feature is crucial for industries where contamination or fluid loss can result in significant operational costs and environmental concerns. Overall, the functionality and efficiency of knife gate valves make them a preferred choice for many fluid control applications.

Operating Mechanisms: How Knife Gate Valves Function Effectively

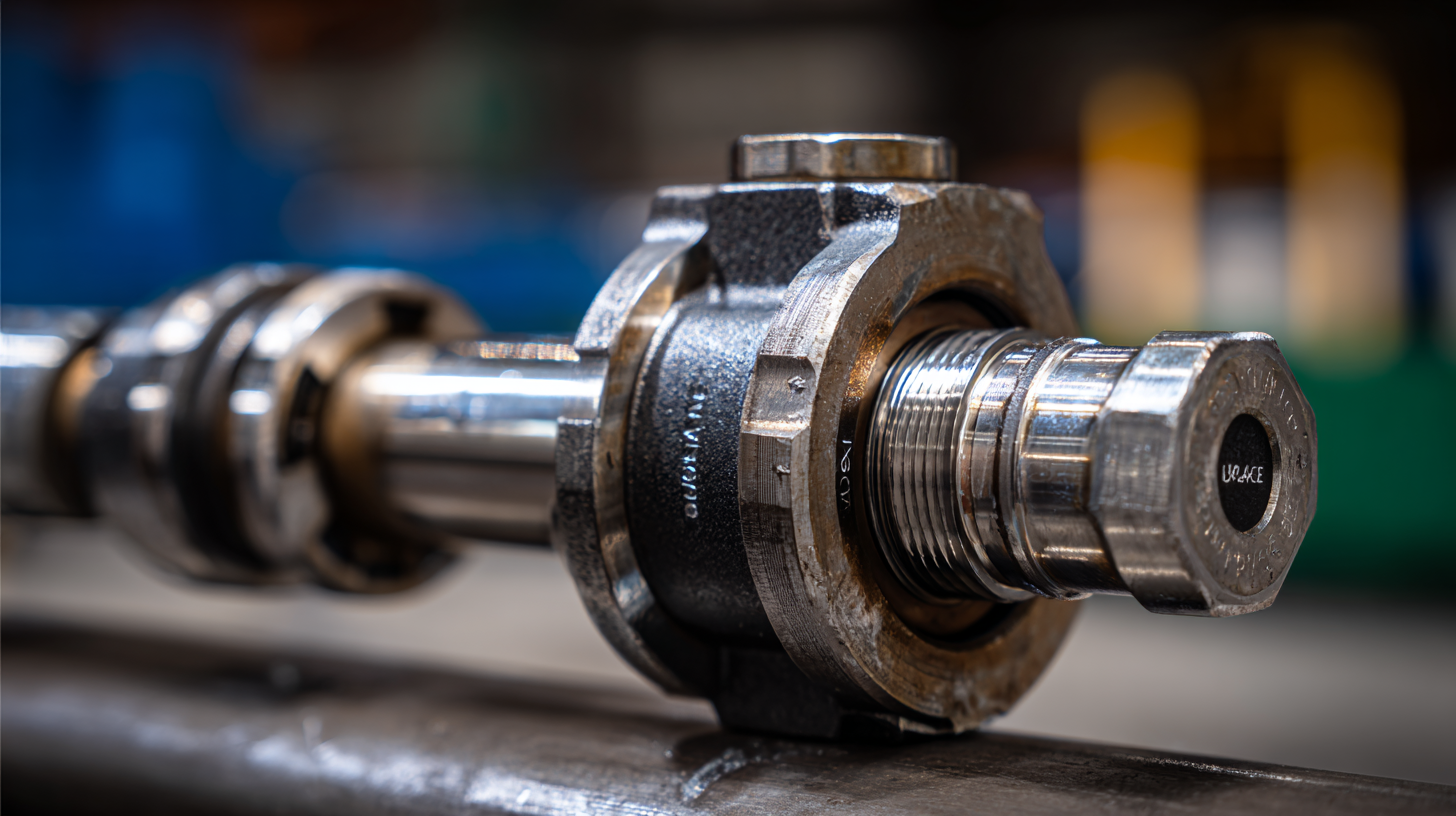

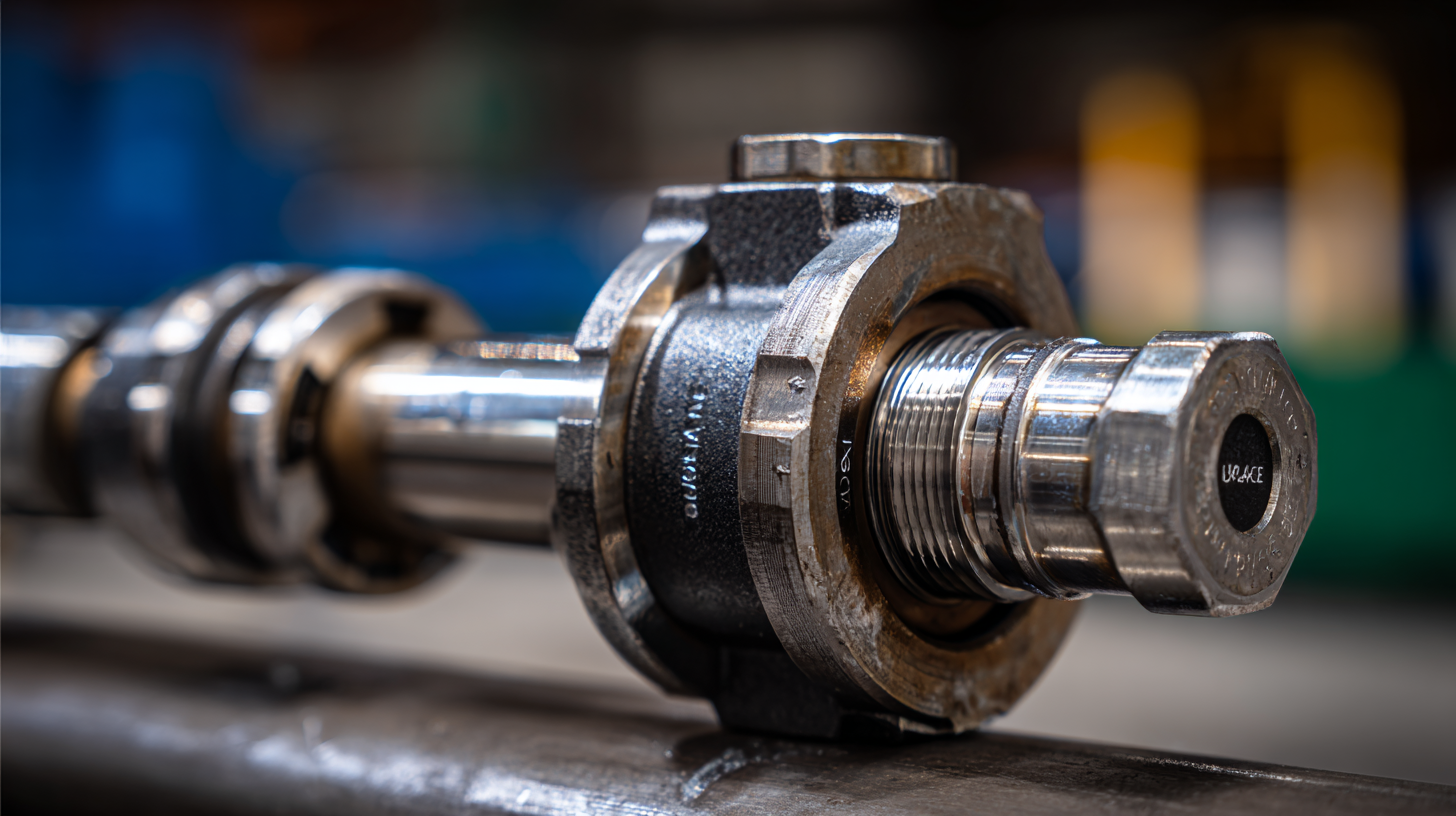

Knife gate valves are essential components in numerous industrial applications, particularly in the management of slurries, liquids, and bulk materials. Their operating mechanism is designed for effective shut-off and control of flow, making them suitable for tasks that require reliable isolation in demanding environments. A knife gate valve typically features a sharp blade that slices through the material, offering minimal resistance and preventing clogging during operation. This unique design not only facilitates efficient flow management but also enhances longevity and performance, especially in dusty or corrosive environments.

Recent advancements in valve technology have broader implications in industries relying on precise flow control. For instance, the introduction of upgraded pinch valves highlights the need for innovative solutions in fluid management. Pinch valves utilize a different yet equally effective shut-off mechanism, employing a pinch bar to create a tight seal. According to industry reports, the valve market is projected to experience significant growth, with the demand for advanced systems like knife gate and pinch valves expected to rise due to increased automation and safety regulations in manufacturing processes. These developments underscore the importance of selecting the right valve for specific operational needs and emphasize ongoing improvements in valve technology for enhanced efficiency and safety.

Maintenance Tips for Ensuring Longevity of Knife Gate Valves

Knife gate valves play an essential role in various industrial applications, primarily in managing the flow of fluids or slurries. To ensure their effective operation and longevity, regular maintenance is paramount. By implementing a routine checkup of the valve components, one can detect any wear or damage before they escalate into more serious issues.

One crucial maintenance tip is to regularly inspect the valve seals and packing. These components can wear down due to continuous operation, causing leaks and reduced efficiency. Replacing seals and packing at the first sign of wear not only enhances performance but also prevents costly downtime. Furthermore, lubricating the valve mechanism can significantly enhance its functionality, minimizing friction and wear over time.

Additionally, if the knife gate valve operates in a highly corrosive environment, it's vital to apply protective coatings and choose materials that resist corrosion during the initial installation. This proactive approach can dramatically extend the valve's operational life, reducing the need for frequent replacements and repairs. Keeping detailed maintenance records can also be valuable, allowing operators to track performance trends and predict potential failures.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.