Understanding the Importance of Ball Check Valves in Modern Fluid Systems

In contemporary fluid systems, the ball check valve plays a crucial role in ensuring efficient operation and safeguarding against backflow.

According to a report by the Global Check Valve Market Analysis, the demand for check valves, including ball check valves, is anticipated to reach approximately $8 billion by 2025, with a compound annual growth rate (CAGR) of 5.6% from 2020.

This growth underscores the increasing importance of reliability and performance in fluid management applications across various industries, from water treatment to oil and gas.

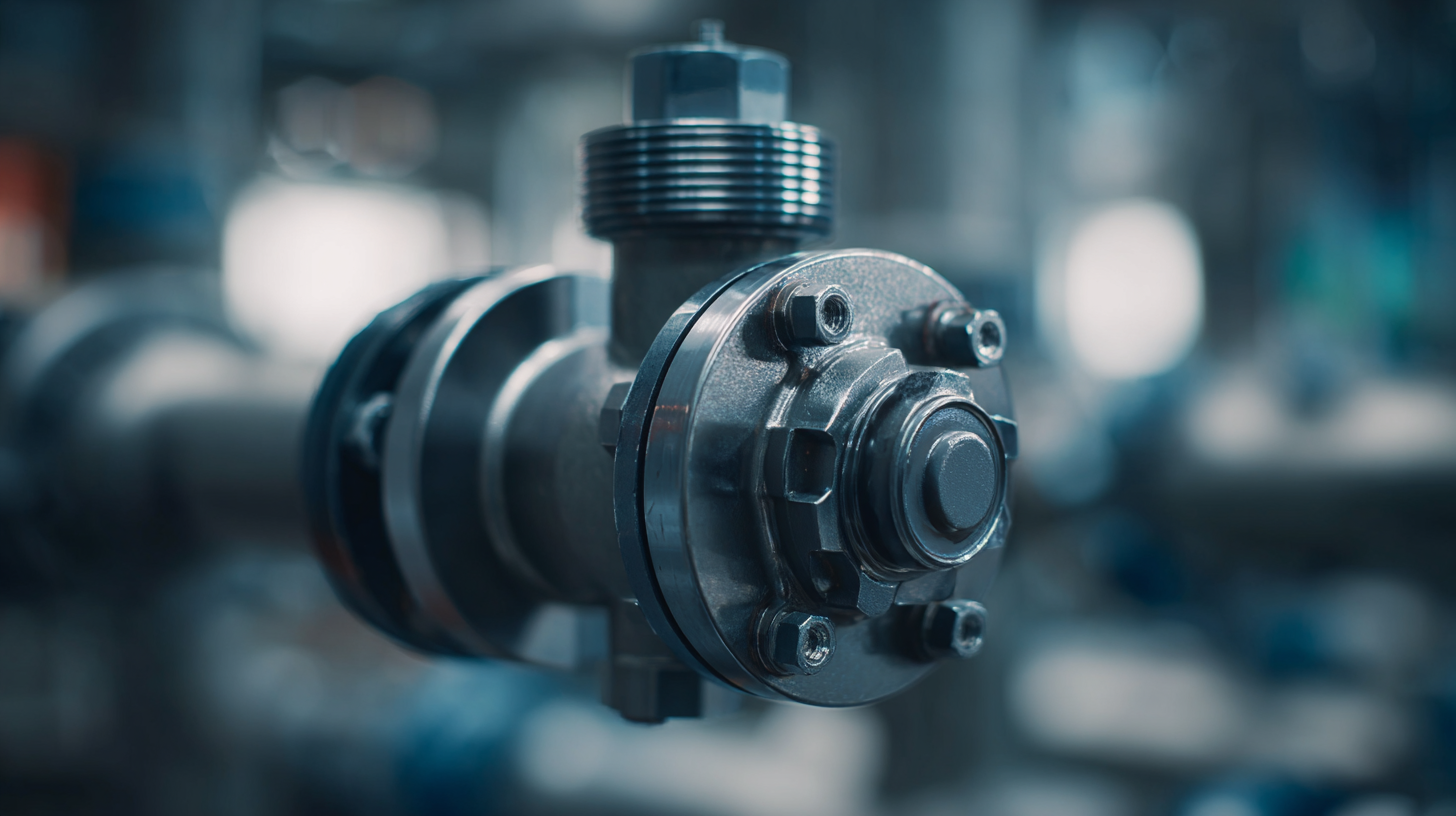

Ball check valves are particularly valued for their simple, effective design that allows for smooth fluid flow in one direction while preventing reverse flow, enhancing system integrity.

As industries continue to evolve, understanding the significance of these components is essential for optimizing fluid dynamics and minimizing operational risks.

How to Identify the Right Ball Check Valve for Your Fluid System Needs

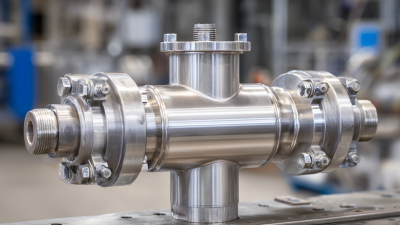

When selecting the right ball check valve for your fluid system needs, it's crucial to consider several key factors that impact efficiency and reliability. A ball check valve plays a vital role in preventing backflow in piping systems, making it essential for maintaining the integrity of your fluid transport. Identify the specific application requirements—such as the type of fluid being transported, pressure ranges, and temperature conditions—since these factors will guide you toward the most suitable valve materials and designs.

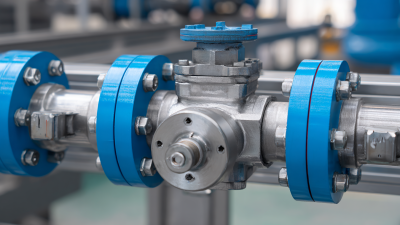

Additionally, pay attention to the operation and maintenance aspects of ball check valves. Modern fluid systems, especially those containing mixing valves or recirculating water systems, can be prone to leaks. Even minor leaks can lead to significant water loss and increased operational costs. Ensure that the chosen ball check valve aligns with your system's layout and can withstand the thermal shocks that may occur during water mixing and recirculation. Investing in a high-quality ball check valve will help mitigate risks, optimize performance, and extend the lifespan of your fluid system.

How to Properly Install Ball Check Valves for Optimal Performance

In modern fluid systems, the installation of

ball check valves

is critical for ensuring optimal performance. Proper installation is essential to prevent backflow and maintain the system's efficiency.

According to recent market reports, the

valves in mining market

is projected to grow by USD 1.56 billion between 2025 and 2029, driven in part by advancements in smart mining technologies.

This growth underscores the necessity for high-performance components like

ball check valves,

which are integral to achieving reliable fluid control in various applications, including mining and HVAC systems.

To achieve peak functionality, it’s important to follow

best practices

during the installation of ball check valves. Incorrect positioning can lead to operational inefficiencies, such as

pressure loss

and increased energy consumption. For example, automated systems are increasingly reliant on sophisticated control valves equipped with

actuators

to optimize performance. This trend points to the importance of selecting the right valve type and ensuring it is installed correctly to respond promptly to changes in fluid dynamics, thus enhancing overall system efficiency and safety.

How to Maintain and Troubleshoot Ball Check Valves Effectively

Ball check valves are crucial components in modern fluid systems, ensuring one-way flow and preventing backflow, which can lead to system inefficiencies and potential damage. However, like any mechanical component, they require regular maintenance and troubleshooting to function optimally. According to a report by the Fluid Control Institute, improper maintenance of check valves can lead to a 20% reduction in system performance.

To maintain ball check valves effectively, it's essential to conduct regular inspections. Look for signs of wear, corrosion, or blockage. Ensure that the valve seats are clean and free from debris, as even minor obstructions can significantly impact performance. Additionally, lubricating moving parts periodically can enhance longevity and reliability.

Tips: Always refer to the manufacturer's guidelines for specific maintenance protocols. Utilizing ultrasonic cleaning methods can be particularly effective for removing buildup without causing damage. When troubleshooting, pay close attention to any unusual noises or vibrations, as these can be indicators of underlying issues that need addressing promptly. A proactive approach will not only ensure the smooth operation of your fluid systems but also extend the life of your ball check valves.

How to Select Ball Check Valves Based on Fluid Characteristics

When selecting ball check valves for modern fluid systems, understanding the characteristics of the fluid is essential. Factors such as fluid viscosity, temperature, and chemical composition significantly influence the performance and longevity of the valve. For instance, a fluid with high viscosity may require a valve with a larger orifice to maintain adequate flow rates without excessive pressure drop. Similarly, aggressive or corrosive fluids necessitate valves made from materials that offer superior resistance, ensuring reliable operation over time.

**Tips:** Always consult manufacturer specifications to determine the most compatible materials for your application. Conducting thorough fluid analysis can help in identifying optimal valve characteristics, reducing maintenance costs in the long run.

Additionally, consider the pressure conditions and potential for backflow within your fluid system. The right ball check valve will prevent reverse flow and protect upstream components, which is vital for system integrity. For low-pressure systems, simple designs may suffice, but high-pressure applications often demand more robust and durable valves.

**Tips:** Regularly review your system's performance data to identify any changes in fluid properties, which might indicate a need for valve adjustments or replacements to preserve efficiency and safety.

How to Understand the Benefits of Ball Check Valves in Preventing Backflow

Ball check valves play a crucial role in modern fluid systems, particularly in preventing backflow, which can lead to contamination and system inefficiencies. One of the primary benefits of ball check valves is their simple yet effective design.

When fluid flows in the intended direction, the ball inside the valve is lifted, allowing for unhindered passage. Conversely, if backflow occurs, the ball drops and seals off the passage, effectively blocking any reverse flow. This mechanism not only safeguards the integrity of the system but also ensures that downstream components operate reliably without the risk of contaminated fluids.

Moreover, ball check valves are favored for their low maintenance requirements and durability. Unlike other types of backflow prevention devices, they have fewer moving parts, which minimizes wear and tear. This characteristic not only extends the lifespan of the valves but also reduces the likelihood of failure and the need for frequent replacements. In sectors such as water treatment, chemical processing, and HVAC systems, the reliability and efficiency provided by ball check valves make them an indispensable component for maintaining optimal fluid flow and protecting system integrity.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.