Understanding the Importance of Inline Check Valves in Preventing Backflow in Industrial Applications

In industrial applications, maintaining the integrity of fluid systems is paramount to operational efficiency and safety.

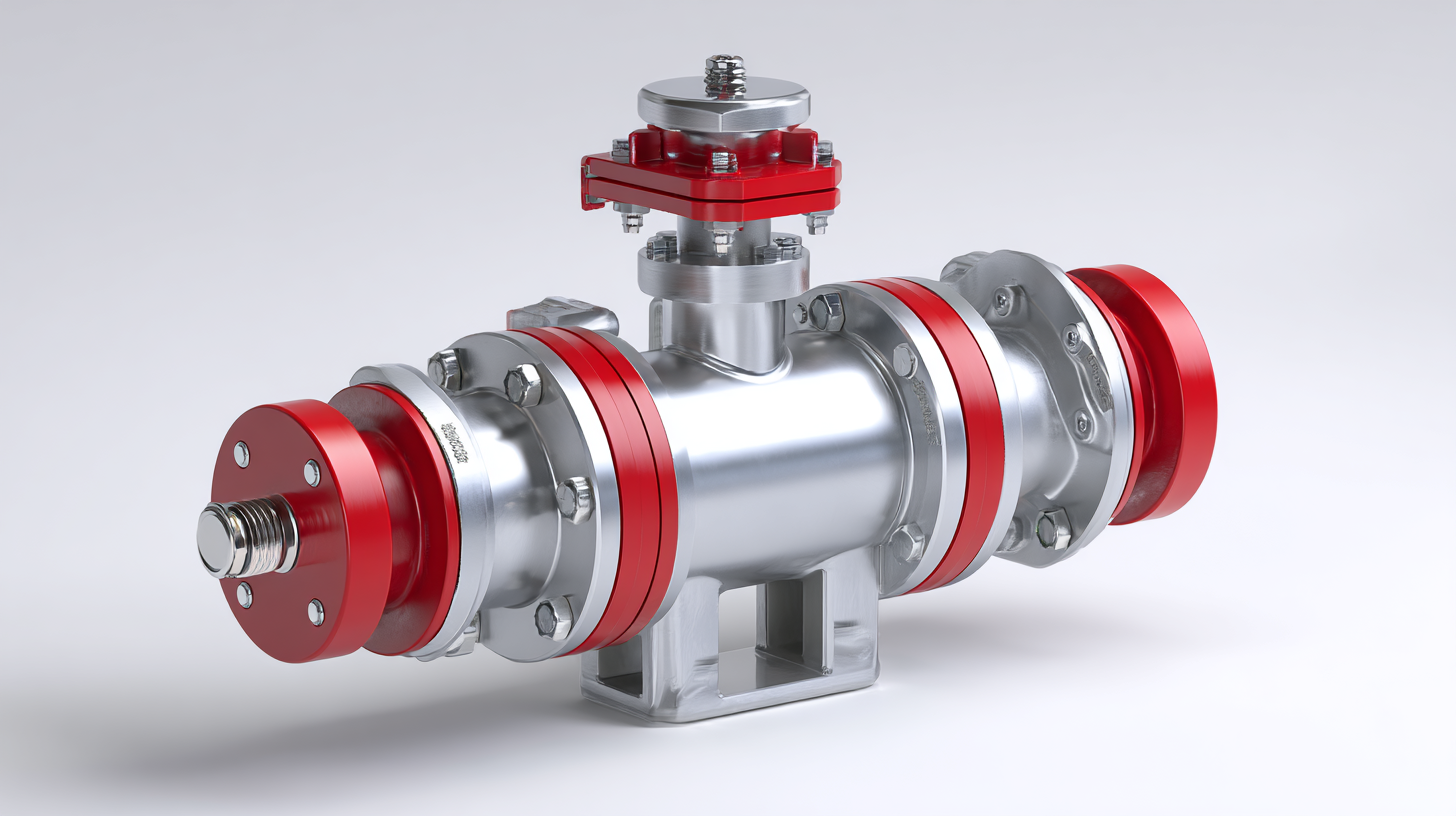

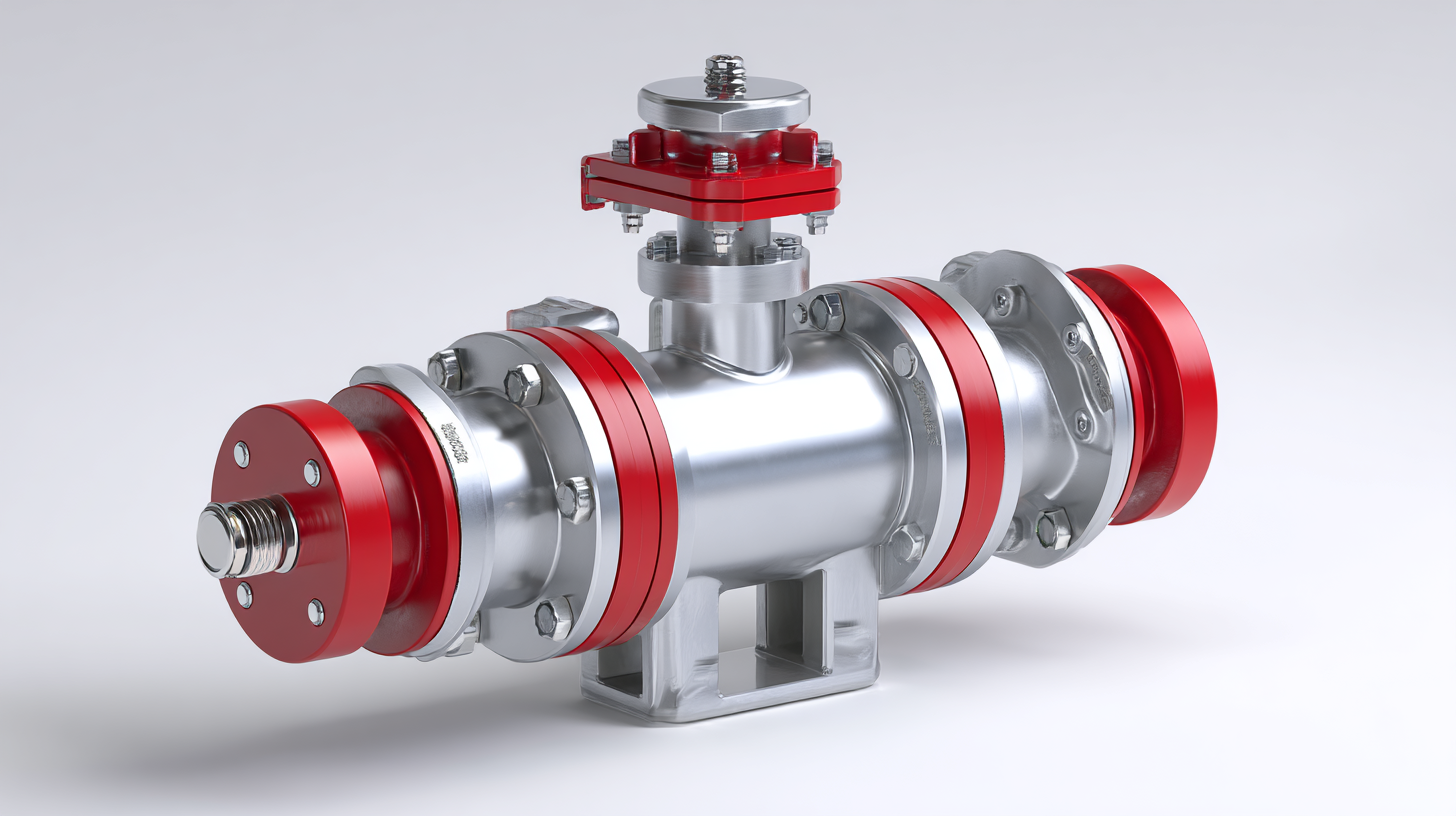

Inline check valves, designed to prevent backflow and ensure one-way fluid movement, play a critical role in achieving this goal.

According to a report by the International Association of Plumbing and Mechanical Officials (IAPMO), improper backflow management can lead to significant contamination issues,

affecting not only production processes but also environmental safety.

Industries that require precisely controlled fluid flow, such as oil and gas, pharmaceuticals, and water treatment,

have increasingly recognized the necessity of incorporating high-quality inline check valves in their systems.

The American Society of Mechanical Engineers (ASME) indicates that failures due to backflow can result in operational downtimes that cost industries millions annually.

Therefore, understanding the importance of inline check valves is essential for engineers and decision-makers,

highlighting the need for effective strategies to prevent backflow in today’s demanding industrial landscape.

In industrial applications, maintaining the integrity of fluid systems is paramount to operational efficiency and safety.

Inline check valves, designed to prevent backflow and ensure one-way fluid movement, play a critical role in achieving this goal.

According to a report by the International Association of Plumbing and Mechanical Officials (IAPMO), improper backflow management can lead to significant contamination issues,

affecting not only production processes but also environmental safety.

Industries that require precisely controlled fluid flow, such as oil and gas, pharmaceuticals, and water treatment,

have increasingly recognized the necessity of incorporating high-quality inline check valves in their systems.

The American Society of Mechanical Engineers (ASME) indicates that failures due to backflow can result in operational downtimes that cost industries millions annually.

Therefore, understanding the importance of inline check valves is essential for engineers and decision-makers,

highlighting the need for effective strategies to prevent backflow in today’s demanding industrial landscape.

The Critical Role of Inline Check Valves in Industrial Systems

Inline check valves play a critical role in industrial systems by preventing backflow, which can lead to system inefficiencies and safety hazards. As industries increasingly automate and optimize their processes, the demand for reliable components such as inline check valves becomes paramount. The global valve market is projected to exceed USD 8.6 billion in 2024, growing at a significant rate, highlighting the importance of these devices in maintaining operational integrity and safety standards across various applications.

Recent advancements in industrial control systems also emphasize the necessity for precise and reliable valve operation. For instance, the ISA-75 series of standards provides guidelines for control valve design and testing, ensuring that these components perform reliably under various conditions. Inline check valves not only support systems like pneumatic and hydraulic controls, but they are fundamental in sectors shifting towards cleaner energy sources, such as liquefied natural gas. By effectively preventing backflow, inline check valves contribute to cutting-edge solutions that enhance the efficiency, safety, and reliability of industrial applications.

Top 5 Benefits of Inline Check Valves in Preventing Backflow

Inline check valves play a crucial role in preventing backflow in various industrial applications, ensuring operational efficiency and system integrity. One of the primary benefits is the protection of equipment and pipelines. By allowing fluid to flow in one direction while preventing backward flow, these valves safeguard pumps and downstream equipment from damage caused by reverse pressure, which can lead to costly repairs and downtime.

Inline check valves play a crucial role in preventing backflow in various industrial applications, ensuring operational efficiency and system integrity. One of the primary benefits is the protection of equipment and pipelines. By allowing fluid to flow in one direction while preventing backward flow, these valves safeguard pumps and downstream equipment from damage caused by reverse pressure, which can lead to costly repairs and downtime.

Another significant advantage is the enhancement of system reliability. Inline check valves contribute to maintaining consistent flow rates, ensuring that processes operate smoothly. This reliability is vital in industries such as water treatment, chemical processing, and oil and gas, where even minor disruptions can result in significant operational challenges. Additionally, the installation of these valves minimizes the risk of contamination, as they prevent the backflow of fluids that may carry pollutants or hazardous substances into clean systems, thereby promoting safety and compliance with health regulations.

Key Design Features of Inline Check Valves for Optimal Performance

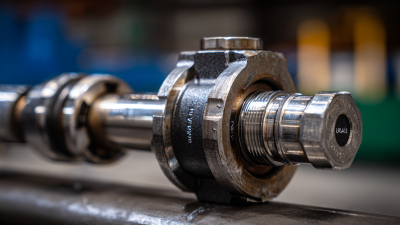

Inline check valves play a crucial role in various industrial applications by preventing backflow and ensuring fluid integrity in systems. The design features of these valves are tailored for optimal performance, particularly in environments requiring reliability under pressure. They are often equipped with spring-loaded mechanisms that allow for rapid response to pressure changes, ensuring that backflow is effectively mitigated. According to industry reports, the demand for such valves will continue to surge, driven by growth in sectors such as wastewater management and hydraulic systems, where maintaining system efficiency is paramount.

Recent advancements in manufacturing technology, such as 3D printing, have paved the way for designing more compact and efficient inline check valves. This innovation supports industries seeking to streamline their systems while enhancing performance capabilities. In fact, the valve market is projected to expand significantly, with increased demand from the semiconductor industry alone driving growth and innovation. Industry experts anticipate that effective valve design, including those that incorporate advanced features for preventing backflow, will be essential in supporting the evolving needs of industrial processes.

How Inline Check Valves Enhance Safety and Efficiency in Industrial Applications

Inline check valves play a critical role in enhancing safety and efficiency within various industrial applications. By preventing backflow, these valves ensure that fluids and gases flow in one direction, mitigating the risks associated with system contamination and equipment damage. In sectors where precise fluid management is essential—such as chemical processing or water treatment—inline check valves serve as a crucial safeguard, allowing operations to run smoothly while protecting valuable resources and equipment.

Furthermore, the operational efficiency of industrial systems is significantly improved with the integration of inline check valves. They help maintain pressure levels, reduce the likelihood of leaks, and limit downtime caused by maintenance or failures. As industries increasingly prioritize safety and operational integrity, the demand for reliable components like inline check valves continues to rise. This trend highlights the growing recognition of their importance not just in safety standards, but also in driving overall efficiency in various industrial sectors.

Impact of Inline Check Valves on Industrial Efficiency and Safety

Comparative Analysis: Inline Check Valves vs. Alternative Backflow Prevention Methods

Inline check valves play a critical role in preventing backflow in various industrial applications, ensuring that fluids flow in the intended direction. Unlike alternative backflow prevention methods, which may include complex systems or manual interventions, inline check valves operate automatically, reducing the risk of operational errors. They provide a reliable level of protection, particularly in environments where the integrity of the fluid delivery system is paramount, like in power generation or chemical processing.

When considering backflow prevention, it's essential to assess the energy efficiency and maintenance implications of your choice. For example, in knuckle boom crane operations, the type of control system can significantly affect energy consumption. This highlights the importance of not only the effectiveness of the prevention method but also its environmental impact. Choosing inline check valves can lead to more stable operations with lower maintenance needs compared to other options.

Tips: Always evaluate the specific requirements of your application when selecting a backflow prevention method. Consider factors like system pressure, fluid type, and the potential for contaminants. Regularly inspect and maintain your check valves to ensure optimal performance and longevity.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

In industrial applications, maintaining the integrity of fluid systems is paramount to operational efficiency and safety.

In industrial applications, maintaining the integrity of fluid systems is paramount to operational efficiency and safety.

Inline check valves play a crucial role in preventing backflow in various industrial applications, ensuring operational efficiency and system integrity. One of the primary benefits is the

Inline check valves play a crucial role in preventing backflow in various industrial applications, ensuring operational efficiency and system integrity. One of the primary benefits is the