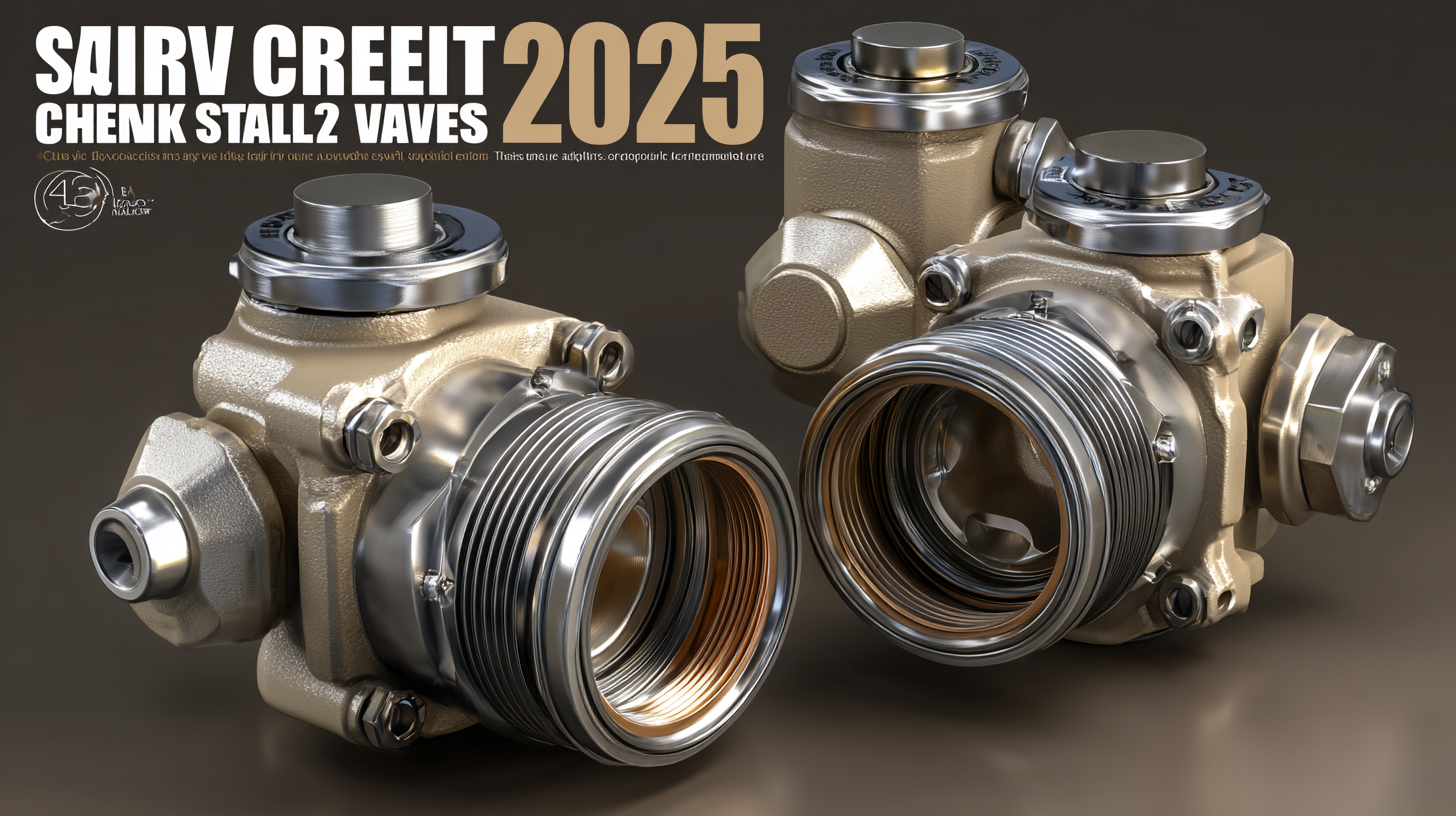

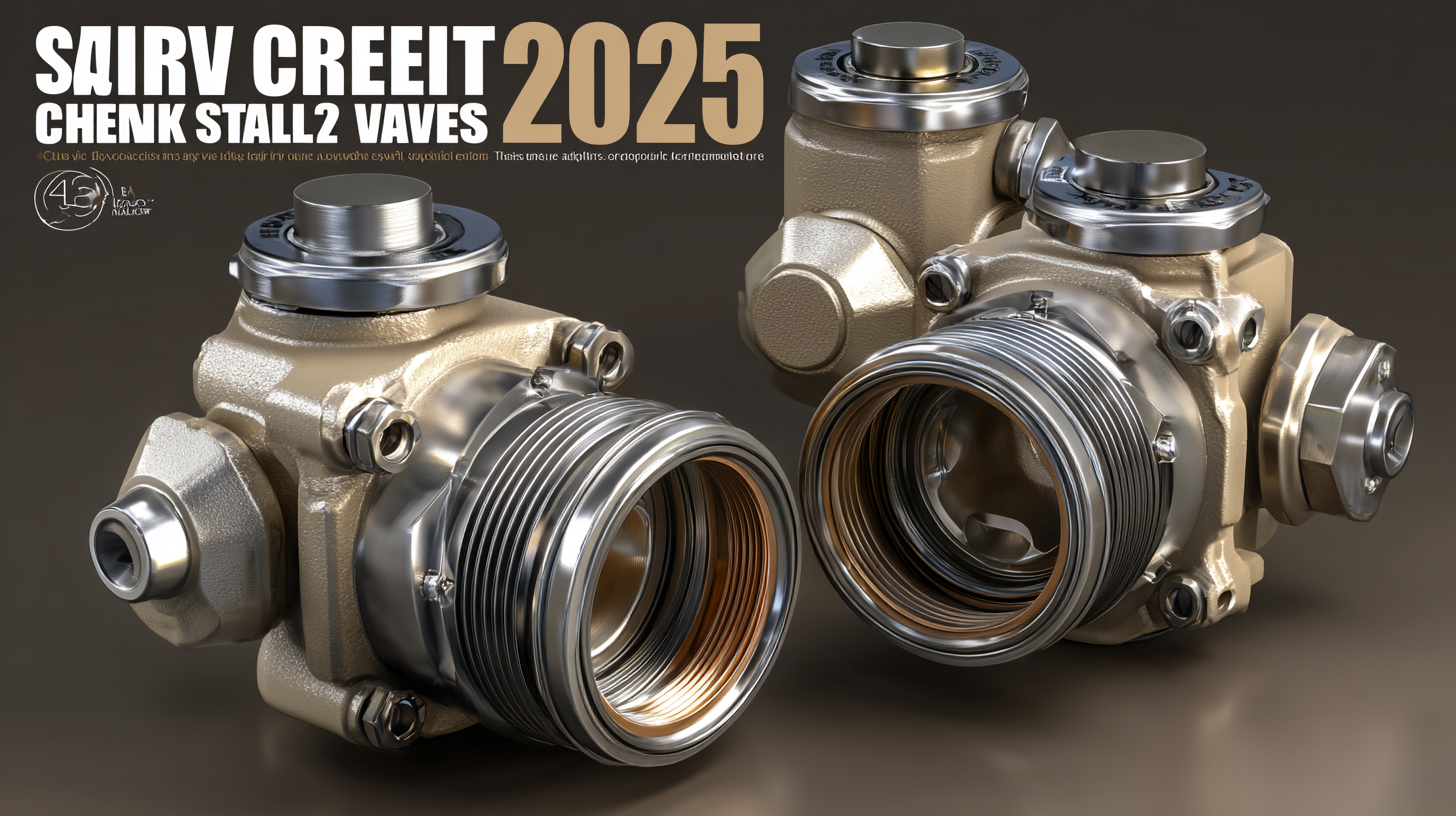

Market Trends for Best Spring Check Valves in 2025 and Innovations Shaping the Future

In 2025, the market for spring check valves is poised for significant transformation, driven by advancements in technology and burgeoning demand across various industries. According to a recent report from MarketsandMarkets, the global valve market is projected to reach USD 101.4 billion by 2026, growing at a CAGR of 6.2% from 2021. Spring check valves, critical for preventing backflow in fluid systems, are experiencing heightened interest due to their reliability and efficiency. Innovations such as smart check valves incorporating IoT technology are set to revolutionize the sector, improving operational efficiency and monitoring capabilities. As industries increasingly prioritize sustainability and energy efficiency, understanding the latest trends and comparisons in spring check valve technology will be essential for stakeholders looking to stay competitive in this dynamic landscape.

Emerging Materials Driving Spring Check Valve Innovations in 2025

The spring check valve market is witnessing a transformative shift as innovative materials reshape product designs and enhance performance. According to a report by the Global Valve Market Research Institute, the demand for lightweight yet durable materials such as advanced polymers and composites is expected to rise significantly by 2025. These materials not only improve corrosion resistance but also reduce the overall weight of the valves, making them more efficient for various applications, particularly in harsh environments.

Furthermore, the integration of smart materials in the design of spring check valves is sparking a new wave of innovation. As indicated by the International Society for Intelligent Systems in Engineering, the adoption of shape memory alloys allows for more adaptive behavior in check valves. This technology enables the valves to respond dynamically to changes in pressure and flow, ensuring better operational reliability and longer service life. As the industry progresses, manufacturers focusing on these emerging materials will likely lead the market, catering to the increasing demand for efficient and reliable fluid control solutions.

Key Market Trends Impacting Spring Check Valve Designs for Enhanced Performance

In recent years, the spring check valve market has witnessed significant transformations driven by innovations focused on enhanced performance. According to a report by Global Industry Analysts, the global check valves market is projected to reach USD 10 billion by 2025, with spring check valves increasingly favored due to their reliability and efficiency. The ongoing trend toward automation in industrial applications necessitates the development of high-performance spring check valves that can withstand varying pressure conditions while maintaining operational integrity.

Moreover, advancements in materials technology are shaping the future of spring check valve designs. Innovations such as corrosion-resistant alloys and advanced polymers are being utilized to improve durability and reduce maintenance requirements. A key report by Research and Markets indicates that the adoption of lightweight materials in fluid control systems could enhance flow efficiency by up to 15%, pointing to an industry shift toward not just performance but sustainability. As manufacturers explore these trends, the integration of smart technologies, including IoT-enabled sensors, is also on the rise, allowing for real-time performance monitoring and predictive maintenance, ultimately driving down operational costs.

Sustainability Practices in Manufacturing Spring Check Valves: A 2025 Perspective

As the demand for environmentally friendly solutions grows, the manufacturing of spring check valves is increasingly adopting sustainability practices. By 2025, it is projected that over 70% of manufacturing processes in this sector will prioritize green technologies, as highlighted in a recent industry report. This transformation not only reduces the carbon footprint but also enhances operational efficiency, making it a win-win for manufacturers and the environment alike.

One way manufacturers are embracing sustainability is through the integration of innovative materials and processes that minimize waste. For instance, the use of recycled metals and low-impact production methods can significantly reduce resource consumption. Furthermore, advancements in technology, including variable valve timing systems, are enhancing product performance while aligning with sustainable practices. According to experts, such innovations can improve engine efficiency by up to 15%, illustrating a crucial intersection of performance and eco-friendliness.

Tips: When selecting spring check valves, look for certifications indicating environmentally responsible production processes. Additionally, consider valves designed for modularity and maintenance simplicity to lower your overall lifecycle impact. Staying informed about market trends and innovations can help businesses make smarter, more sustainable purchasing decisions.

Technological Advancements Revolutionizing Spring Check Valve Functionality

In recent years, technological advancements have significantly transformed the functionality of spring check valves, particularly as industries strive for enhanced efficiency and sustainability. According to a report by Research and Markets, the global check valves market is projected to grow at a CAGR of 5.32% from 2022 to 2027. This growth can be attributed to innovations such as smart valve technology, which integrates IoT capabilities to monitor and control fluid flow in real-time. The ability to detect anomalies and optimize performance not only enhances system reliability but also extends the lifespan of these critical components.

Moreover, the adoption of advanced materials like composites and polymers is reshaping the design and performance of spring check valves. A study published by Mordor Intelligence highlights that these materials can withstand higher pressures and temperatures, thereby increasing their applicability across various sectors, including oil and gas, water treatment, and HVAC systems. The move towards eco-friendly manufacturing processes is also gaining momentum, with industry leaders prioritizing sustainability in their production methodologies. As we look ahead to 2025, these innovations are set to revolutionize spring check valve technology, making them more efficient, durable, and environmentally friendly.

Predicted Customer Demands and Preferences for Spring Check Valves in 2025

As we look ahead to 2025, customer demands for spring check valves are projected to shift significantly in response to evolving industry needs and technological advancements. A recent report by Research and Markets estimates that the global market for check valves will reach $8.5 billion by 2025, driven by increased investments in infrastructure and energy sectors. Customers are increasingly prioritizing durability and efficiency, with a growing preference for valves that can operate effectively under varying pressure conditions.

Moreover, innovations in materials science are set to revolutionize the spring check valve industry. According to a study by Grand View Research, the adoption of corrosion-resistant materials is expected to rise by nearly 25% over the next few years, reflecting customer preferences for longer-lasting solutions in challenging environments. Additionally, the integration of smart technologies, such as IoT capabilities for real-time monitoring, is anticipated to enhance customer satisfaction by providing greater control and insights into valve performance, aligning with the expected demand for smarter, more connected systems in the fluid control market.

Market Trends for Spring Check Valves in 2025

This chart presents predicted customer demands and preferences for spring check valves in 2025 across various applications, reflecting shifts in market trends and innovations.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.