Top Strategies for Maximizing Efficiency with High Performance Butterfly Valves

In today's industrial landscape, maximizing efficiency is paramount, particularly in processes involving fluid control and management. High performance butterfly valves have emerged as critical components in this quest, offering significant advantages over traditional valve types. According to the latest report from Research and Markets, the global butterfly valve market is projected to reach $6.6 billion by 2025, driven by the increasing demand for efficient fluid handling solutions across various sectors, including oil and gas, water treatment, and manufacturing. With their ability to provide tight sealing, quick operation, and reduced energy consumption, high performance butterfly valves play a vital role in improving system efficiency. This blog will explore top strategies for leveraging these advanced valves to enhance operational performance, reduce costs, and achieve sustainable practices in fluid management systems.

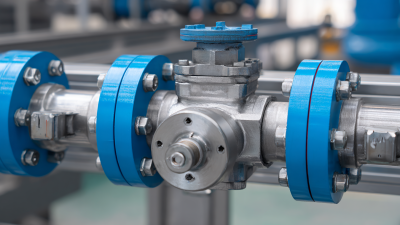

Understanding the Different Types of High-Performance Butterfly Valves

High-performance butterfly valves are essential components in various industries due to their efficiency and versatility. Understanding the different types of these valves can significantly impact operational effectiveness. The most common types include resilient seated, metal seated, and high-performance designs. Each type is engineered for specific applications, with performance metrics such as pressure rating and temperature tolerance varying significantly. For instance, according to a recent industry report, high-performance butterfly valves can withstand pressures up to 250 PSI and temperatures reaching 400°F, making them ideal for demanding environments.

Tip 1: When selecting a butterfly valve, ensure it aligns with the operational requirements—consider factors such as flow capacity and media compatibility. Metal seated valves are particularly beneficial for high-temperature applications, while resilient seated valves often provide better sealing under lower pressures.

Additionally, the design of the valve’s body and disc plays a crucial role in efficiency. High-performance options often feature a streamlined design that minimizes turbulence and pressure drop across the valve. A study indicated that an optimized design can lead to a 25% reduction in energy consumption compared to traditional models.

Tip 2: Regular maintenance and inspections can enhance the lifespan and performance of butterfly valves. Implement a routine check for signs of wear and ensure that the valve's seal is intact to prevent leaks and pressure loss, optimizing overall system efficiency.

Key Features that Enhance Efficiency in Butterfly Valve Design

Butterfly valves are essential components in numerous industrial applications, and their efficiency directly impacts operational performance. One key feature that enhances the efficiency of butterfly valve design is the optimized disc shape. A streamlined disc reduces fluid turbulence and pressure loss, allowing for smoother flow rates. This design improvement not only maximizes flow efficiency but also contributes to less energy consumption, making the overall system more sustainable.

Another significant feature is the use of high-performance materials. Advanced materials such as stainless steel or specialized alloys can withstand extreme conditions and corrosive environments. This durability extends the lifespan of the valve, reducing the need for frequent replacements and maintenance. Additionally, these materials can provide better sealing capabilities, preventing leaks and ensuring system integrity. Together, these features create a butterfly valve that is not only efficient but also reliable, supporting long-term operational success in various industries.

Top Strategies for Maximizing Efficiency with High Performance Butterfly Valves

| Key Feature |

Description |

Impact on Efficiency |

Example Application |

| Short-Path Design |

Minimizes turbulence and pressure drop. |

Improves flow rates and energy efficiency. |

Power Plants |

| Aerodynamic Disc Shape |

Reduces drag and enhances flow capacity. |

Enhances system performance. |

Water Treatment Facilities |

| PTFE Seals |

Provides excellent sealing while reducing friction. |

Prevents leakage and reduces energy loss. |

Chemical Processing |

| Actuator Efficiency |

Utilizes low power actuators for optimal performance. |

Lowers operational costs and energy consumption. |

HVAC Systems |

| Corrosion Resistance Materials |

Ensures long service life and reliability. |

Reduces maintenance costs and downtime. |

Oil and Gas Pipelines |

Applications of Butterfly Valves in Various Industries

Butterfly valves play a vital role in various industries due to their efficiency and functionality in flow regulation. In the water treatment sector, for example, these valves are instrumental in controlling water distribution systems. According to a report by MarketsandMarkets, the global butterfly valve market is expected to reach $6.4 billion by 2024, growing at a CAGR of 5.4%. This growth is driven by the increasing demand for efficient water management systems and the adoption of automation in industrial processes.

In the oil and gas industry, butterfly valves are preferred for their lightweight design and quick shut-off capabilities. A study by Research and Markets highlights that around 30% of the butterfly valves produced are utilized in oil and gas applications due to their ability to withstand high pressure and temperature. This makes them indispensable for upstream and downstream operations, where pressure regulation is crucial.

Tip: When selecting butterfly valves for your projects, consider the material and design that best suits your application. For corrosive environments, stainless steel valves are ideal, while plastic variants work well in less demanding settings. Additionally, ensure proper sizing to avoid unnecessary pressure drops and maintain system efficiency. Proper maintenance of these valves can also extend their lifespan significantly, enhancing overall operational efficiency across various industries.

Maintenance Practices to Ensure Optimal Performance of Butterfly Valves

Maintaining optimal performance of butterfly valves is crucial for ensuring system efficiency and reliability. According to a 2021 report by the Valve Manufacturers Association, approximately 20% of valve failures can be attributed to inadequate maintenance practices. Regular inspections, including visual checks for wear and corrosion, can help identify issues before they lead to significant downtime or costly repairs. Establishing a routine maintenance schedule can significantly enhance the lifespan and functionality of butterfly valves, yielding a return on investment that averages 25% over three years.

In addition to regular inspections, proper lubrication is essential to ensure smooth operation. Industry studies indicate that lubricated butterfly valves can improve valve life by up to 40%, reducing the frequency of replacements and maintenance interventions. Utilizing high-quality lubricants specifically designed for valve applications can mitigate the risks of sticking, increased torque, and subsequent valve failure. Furthermore, training staff on correct operation techniques, supported by guidelines from organizations like the American National Standards Institute (ANSI), can lead to more efficient use and longer service intervals for butterfly valves.

Top Strategies for Maximizing Efficiency with High Performance Butterfly Valves

This chart illustrates the efficiency rates of different maintenance practices for butterfly valves. Regular maintenance is crucial to achieving optimal performance and preventing failures.

Comparative Analysis: Butterfly Valves vs. Other Valve Types for Efficiency

When evaluating the efficiency of butterfly valves compared to other valve types, several industry reports highlight their superior performance in diverse applications. According to a recent report by the Global Valve Market Research Institute, butterfly valves can reduce energy consumption by up to 30% compared to gate and globe valves, primarily due to their lightweight design and lower pressure drop characteristics. This efficiency is crucial in large-scale systems where fluid dynamics can significantly influence operational costs.

Additionally, a study published in the Journal of Fluid Flow Technology emphasizes that butterfly valves offer rapid throttling and flow control capabilities, which enhance system responsiveness. In contrast, traditional valves, like ball and check valves, often incur higher friction losses and require more space for installation, thereby increasing their overall footprint and maintenance demands. The ability of butterfly valves to maintain flow rates while minimizing resistance makes them a go-to choice for industries ranging from water treatment to pharmaceuticals, where efficiency is paramount.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.