How to Select the Right Hydraulic Check Valve for Your Industrial Applications

In the rapidly evolving landscape of industrial applications, selecting the appropriate hydraulic check valve is crucial for enhancing system efficiency and reliability. According to a recent report by MarketsandMarkets, the global market for hydraulic components is projected to reach $44.6 billion by 2025, driven by increased demand in sectors such as construction, manufacturing, and energy.

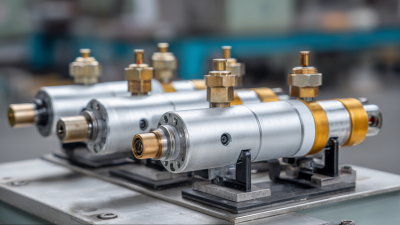

Hydraulic check valves play a pivotal role in maintaining the integrity of hydraulic systems by preventing backflow and ensuring unidirectional fluid flow, which is essential for protecting equipment and enhancing operational safety. Understanding the different types and specifications of hydraulic check valves is vital for engineers and decision-makers aiming to optimize performance and reduce maintenance costs in their systems. This guide will provide insights into how to effectively select the right hydraulic check valve tailored to your industrial needs.

Understanding the Basics: What is a Hydraulic Check Valve?

Hydraulic check valves are essential components in various industrial applications, serving a critical function in controlling the flow of fluids. At their core, a hydraulic check valve is designed to allow fluid to flow in one direction while preventing backflow. This fundamental mechanism helps maintain system efficiency, protects equipment from damage, and ensures the proper operation of hydraulic circuits. Understanding the basics of these valves involves recognizing their construction, which typically includes a movable disc or ball, a seat, and a body that houses these elements. The design of the valve determines its response to pressure changes, dictating when it will open or close.

Selecting the right hydraulic check valve requires consideration of several factors, including the operating pressure, flow rate, and the types of fluids involved in your application. Additionally, the valve's material and size are pivotal in ensuring compatibility with existing systems. When evaluating options, it’s important to analyze specifications and performance characteristics to match the check valve's features with the demands of the hydraulic system. Ultimately, making informed decisions about hydraulic check valves can lead to enhanced system reliability and efficiency, reducing potential maintenance and operational costs.

How to Select the Right Hydraulic Check Valve for Your Industrial Applications

| Parameter |

Description |

Typical Value |

| Type |

Type of hydraulic check valve, such as spring-loaded or pilot-operated |

Spring-loaded |

| Material |

Material from which the valve is made, affecting durability and compatibility |

Steel, Stainless Steel |

| Pressure Rating |

Maximum pressure the valve can withstand |

4000 psi |

| Port Size |

Size of the inlet and outlet ports |

1/2 inch |

| Flow Rate |

The rate at which fluid can pass through the valve |

20 GPM |

| Temperature Range |

Operating temperature range of the valve |

-20°F to 250°F |

| Installation |

Recommended installation orientation |

Vertical or Horizontal |

Key Factors to Consider When Choosing a Hydraulic Check Valve

When selecting the right hydraulic check valve for industrial applications, several key factors must be considered to ensure optimal performance and reliability. The most critical factor is the pressure rating; it should match or exceed the system's maximum operating pressure. According to a report by the International Fluid Power Society, approximately 30% of hydraulic system failures can be attributed to improper valve pressure ratings, highlighting the importance of accurate specifications.

Another vital consideration is the flow rate compatibility. Ensuring that the check valve can handle the expected flow rate is essential to prevent cavitation and maintain system efficiency. A well-chosen valve will have a flow coefficient (Cv) suitable for the application's requirements. In studies, it was shown that using the correct Cv can improve system efficiency by up to 15%, thus directly impacting overall operational costs.

Tips: Always consult manufacturer data sheets for specific flow and pressure ratings before making a selection. Additionally, consider the material of the check valve, as it should be compatible with the fluids being used to avoid corrosion and other chemical interactions. Proper installation and alignment can also significantly enhance the life span of your hydraulic check valve, with misalignment being a common cause of premature failure.

Comparison of Different Types of Hydraulic Check Valves on the Market

When selecting the right hydraulic check valve for your industrial applications, it's crucial to understand the varying types available in the market. Hydraulic check valves primarily serve to prevent backflow in a hydraulic system, ensuring that fluid only moves in the desired direction.

The two most common types are spring-loaded check valves and pilot-operated check valves. Spring-loaded check valves are simple and compact, making them ideal for applications with lower pressure and flow requirements. They rely on a spring mechanism to seal the valve when there is no flow, which also allows for quick response times.

In contrast,

pilot-operated check valves are more suitable for high-pressure environments. These valves use a pilot pressure to keep the valve open, allowing for better flow control and reduced risk of cavitation. Ideal for larger systems, they can handle more substantial pressure variations and provide a more robust solution for preventing backflow. Understanding these differences and the specific needs of your application is key to making an informed decision. By comparing the features, benefits, and typical applications of each valve type, you can effectively determine the right hydraulic check valve for your operational demands.

How Material Selection Affects Hydraulic Check Valve Performance

When selecting a hydraulic check valve for industrial applications, the material of construction plays a pivotal role in determining overall performance and longevity. Different materials, such as cast iron, stainless steel, and plastic composites, exhibit varying resistance to corrosion, pressure, and temperature fluctuations. According to a report by the Fluid Power Institute, up to 70% of valve failures in industrial settings are attributed to material degradation caused by environmental factors, emphasizing the importance of choosing the right material.

Stainless steel, for example, is often favored in corrosive environments due to its exceptional resistance to rust and chemical attack. In applications exposed to high pressure and temperature, carbon steel with specialized coatings can provide a balance of strength and durability. Data from the American Society of Mechanical Engineers highlight that valves made from appropriate materials can sustain operational pressures up to 20% higher compared to those made from less suitable materials, which can significantly enhance system reliability and reduce maintenance costs. Thus, understanding the specific requirements of your hydraulic system is crucial for selecting the optimal check valve material.

Stainless steel, for example, is often favored in corrosive environments due to its exceptional resistance to rust and chemical attack. In applications exposed to high pressure and temperature, carbon steel with specialized coatings can provide a balance of strength and durability. Data from the American Society of Mechanical Engineers highlight that valves made from appropriate materials can sustain operational pressures up to 20% higher compared to those made from less suitable materials, which can significantly enhance system reliability and reduce maintenance costs. Thus, understanding the specific requirements of your hydraulic system is crucial for selecting the optimal check valve material.

Cost vs. Quality: Finding the Best Value in Hydraulic Check Valves

When selecting hydraulic check valves for industrial applications, balancing cost and quality is crucial. Investing in high-quality valves can lead to long-term savings and improved operational efficiency, while opting for cheaper options often results in maintenance issues and premature replacement. Understanding the specific requirements of your system can help ensure you make a sound investment that maximizes performance.

When selecting hydraulic check valves for industrial applications, balancing cost and quality is crucial. Investing in high-quality valves can lead to long-term savings and improved operational efficiency, while opting for cheaper options often results in maintenance issues and premature replacement. Understanding the specific requirements of your system can help ensure you make a sound investment that maximizes performance.

Tip: Always evaluate the material and design of the check valve. Stainless steel and brass valves are typically more durable and resistant to corrosion, making them suitable for harsh environments despite their higher initial cost.

Another key consideration is the valve's flow rate and pressure rating. Ensure that the check valve you select meets the specifications necessary for your application, as mismatched components can lead to inefficiencies or system failures.

Tip: When in doubt, consult with manufacturers or experts in hydraulic systems. They can provide insights into which products deliver the best quality for your budget and may even suggest options that offer extended warranties or better service support.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

Stainless steel, for example, is often favored in corrosive environments due to its exceptional resistance to rust and chemical attack. In applications exposed to high pressure and temperature, carbon steel with specialized coatings can provide a balance of strength and durability. Data from the American Society of Mechanical Engineers highlight that valves made from appropriate materials can sustain operational pressures up to 20% higher compared to those made from less suitable materials, which can significantly enhance system reliability and reduce maintenance costs. Thus, understanding the specific requirements of your hydraulic system is crucial for selecting the optimal check valve material.

Stainless steel, for example, is often favored in corrosive environments due to its exceptional resistance to rust and chemical attack. In applications exposed to high pressure and temperature, carbon steel with specialized coatings can provide a balance of strength and durability. Data from the American Society of Mechanical Engineers highlight that valves made from appropriate materials can sustain operational pressures up to 20% higher compared to those made from less suitable materials, which can significantly enhance system reliability and reduce maintenance costs. Thus, understanding the specific requirements of your hydraulic system is crucial for selecting the optimal check valve material.

When selecting hydraulic check valves for industrial applications, balancing cost and quality is crucial. Investing in high-quality valves can lead to long-term savings and improved operational efficiency, while opting for cheaper options often results in maintenance issues and premature replacement. Understanding the specific requirements of your system can help ensure you make a sound investment that maximizes performance.

When selecting hydraulic check valves for industrial applications, balancing cost and quality is crucial. Investing in high-quality valves can lead to long-term savings and improved operational efficiency, while opting for cheaper options often results in maintenance issues and premature replacement. Understanding the specific requirements of your system can help ensure you make a sound investment that maximizes performance.