How to Select the Right Pneumatic Valve for Your Application

In the evolving landscape of industrial automation, the selection of the appropriate pneumatic valve plays a critical role in optimizing system performance and efficiency. According to a recent report by MarketsandMarkets, the global pneumatic valve market is projected to reach $21.2 billion by 2025, with a compound annual growth rate (CAGR) of 4.9% from 2020 to 2025. This growth underscores the increasing dependence on pneumatic systems across various sectors, including manufacturing, automotive, and food processing. Given the diverse range of pneumatic valves available, selecting the right one for your specific application can significantly impact operational reliability and cost-effectiveness. By understanding the fundamental criteria for valve selection, engineers and decision-makers can ensure seamless integration into their processes, maximizing both productivity and safety while reducing downtime and maintenance costs.

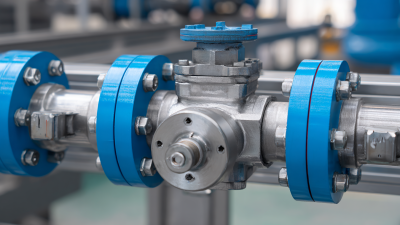

Understanding the Functionality of Different Pneumatic Valve Types

When selecting a pneumatic valve for your application, understanding the functionality of different valve types is crucial. Pneumatic valves are essential components in various industries, controlling the flow and pressure of compressed air crucial for operating machinery. According to a report by MarketsandMarkets, the global pneumatic valves market is expected to reach USD 6.47 billion by 2026, growing at a CAGR of 5.3% from 2021. This growth highlights the increasing application of pneumatic systems across manufacturing, automotive, and packaging sectors.

There are several types of pneumatic valves, including solenoid valves, manual valves, and proportional valves, each serving different operational needs. Solenoid valves, for instance, provide quick and reliable automation, making them ideal for applications requiring precise control and high-speed responsiveness. Data from McKinsey's Industrial Automation report suggests that incorporating solenoid valves can improve automation efficiency by up to 20%. Conversely, proportional valves allow for variable control of flow and pressure, making them suitable for more complex applications that need fine-tuning. Understanding these functionalities enables businesses to select the most appropriate valve type, enhancing operational efficiency and effectiveness.

Comparison of Different Pneumatic Valve Types

This chart displays the flow rates of various types of pneumatic valves commonly used in industrial applications. Understanding these rates can help in selecting the appropriate valve for specific operational needs.

Evaluating Performance and Reliability in Valve Selection

When selecting the right pneumatic valve for your application, evaluating performance and reliability is crucial. The valve you choose must be capable of handling the specific requirements of your system, including pressure, flow rate, and media compatibility. To ensure optimal performance, consider factors such as the valve's response time and duty cycle. A valve that operates smoothly and responds quickly to control signals can significantly enhance the efficiency of your system.

**Tip:** Before making a decision, thoroughly analyze your application’s requirements. Create a checklist of the operating conditions the valve will face, including temperature variations and potential contaminants. This detailed understanding will guide you toward selecting a valve designed for those particular conditions, helping to minimize maintenance and downtime.

Reliability is another key aspect of valve selection. Look for valves that are built with durable materials and are rated for long operational lives. Manufacturers often provide performance data and reliability ratings, which can assist in making informed decisions.

**Tip:** Don’t hesitate to reach out for expert consultations or reviews of customer feedback. Peer insights can highlight any potential issues and help confirm that the valve you choose meets longevity expectations and performance standards in real-world applications.

Assessing Environmental Compatibility for Optimal Valve Use

When selecting the right pneumatic valve for your application, assessing

environmental compatibility is crucial to ensure

optimal performance. Environmental factors, such as

temperature, humidity, and exposure to corrosive substances, can impact a valve's functionality and lifespan.

For instance, materials that fare well in one environment may not withstand another, leading to

premature failure. Therefore, it is important to evaluate

the specific conditions under which the valve will operate before making a decision.

When selecting the right pneumatic valve for your application, assessing

environmental compatibility is crucial to ensure

optimal performance. Environmental factors, such as

temperature, humidity, and exposure to corrosive substances, can impact a valve's functionality and lifespan.

For instance, materials that fare well in one environment may not withstand another, leading to

premature failure. Therefore, it is important to evaluate

the specific conditions under which the valve will operate before making a decision.

Tips: Always consult the manufacturer’s

specifications regarding material compatibility with the

intended environment. Additionally, consider exploring advanced technologies in valve recognition and

performance monitoring. Similar to recent advancements in machine learning for medical applications, integrating

innovative solutions can help in selecting valves that not only meet environmental needs but also demonstrate

reliability over time.

Another vital aspect to consider is the compatibility of the pneumatic valve with other components in your system.

This includes evaluating dimensions, pressure ratings, and actuation methods to prevent potential operational issues.

Conducting a thorough compatibility assessment will minimize downtime and enhance

overall efficiency.

Cost-Effectiveness: Balancing Price and Performance in Pneumatic Valves

When selecting a pneumatic valve, cost-effectiveness is a key factor that cannot be overlooked. According to a recent report by the International Society of Automation, pneumatic valves can represent around 30% of the total cost of a pneumatic system. Therefore, finding the right balance between price and performance is essential for optimizing both operational efficiency and budget constraints.

One approach to achieving cost-effectiveness is to assess the specific needs of your application. For instance, if you are in an industry where precision is critical—like pharmaceuticals—investing in high-performance valves will likely pay off in terms of reduced errors and wastage. On the other hand, industries that deal with less stringent requirements might benefit from more economical options. The report indicates that businesses that effectively align their valve choices with application demands saw an average of 15% reduction in overall system costs.

Tip: Always consider the total cost of ownership when evaluating pneumatic valves, not just the initial purchase price. Maintenance, compatibility, and energy efficiency can significantly impact long-term performance and expenses.

Another critical aspect of balancing cost and performance is understanding the materials of construction. A recent industry survey found that 60% of operators reported frequent valve failures due to material incompatibility with the media being handled. Selecting valves made from materials suited for your specific environment can reduce maintenance costs and improve reliability.

Tip: Consult with manufacturers or industry experts to identify the best material options based on your fluid's characteristics and the operating environment. This step can help prevent costly downtime and ensure that your system runs smoothly.

Maintenance Considerations for Long-Term Valve Efficiency

When selecting the right pneumatic valve for your application, maintenance considerations play a crucial role in ensuring long-term valve efficiency. According to a report by the International Journal of Engineering Research, regular maintenance can reduce the failure rates of pneumatic systems by up to 40%. This underscores the importance of not only choosing the correct valve but also implementing a proactive maintenance strategy to avoid downtime.

Key maintenance strategies include regular inspections, lubrication of moving parts, and replacing seals and gaskets as necessary. A study by the American Society of Mechanical Engineers found that effective maintenance can extend the average life span of pneumatic valves by 20-30%. Moreover, utilizing predictive maintenance technologies can enhance system reliability. For instance, vibration analysis and thermography can detect anomalies before they lead to system failures, thus preserving efficiency and performance.

Furthermore, keeping detailed maintenance logs enables operators to track the condition and performance of pneumatic valves over time. The data gathered can provide valuable insights, leading to informed decisions about maintenance schedules and potential upgrades. By focusing on these maintenance considerations, industries can achieve greater reliability and efficiency in their pneumatic systems, ultimately lowering operational costs and improving overall productivity.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

When selecting the right pneumatic valve for your application, assessing

When selecting the right pneumatic valve for your application, assessing