Top 10 Cryogenic Valves You Need to Know About?

Cryogenic valves play a critical role in various industries, especially in the field of liquefied gases. According to Dr. Emily Phelps, a renowned expert in cryogenic technology, "The reliability of cryogenic valves is paramount for ensuring safety and efficiency." These valves control the flow of gases and liquids at ultra-low temperatures, which is crucial in applications like aerospace and medical technology.

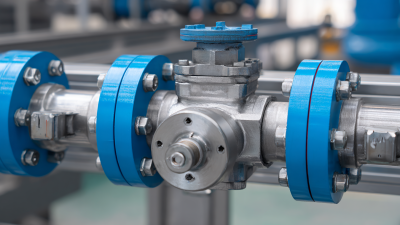

Understanding the top cryogenic valves available can help engineers and technicians make informed decisions. There are various types with unique features. Materials used in manufacturing these valves must withstand extreme temperatures without degrading. This precision is essential in maintaining system integrity and operational safety.

While the advancements in cryogenic valve technology are impressive, challenges remain. Not every valve is suitable for every application. Engineers must consider factors such as pressure and temperature ranges. Ideally, selecting the right valve involves careful analysis and expert insights. Mistakes in this process can lead to severe repercussions. The knowledge of cryogenic valves is essential for industries relying on such technologies.

Overview of Cryogenic Valves and Their Importance

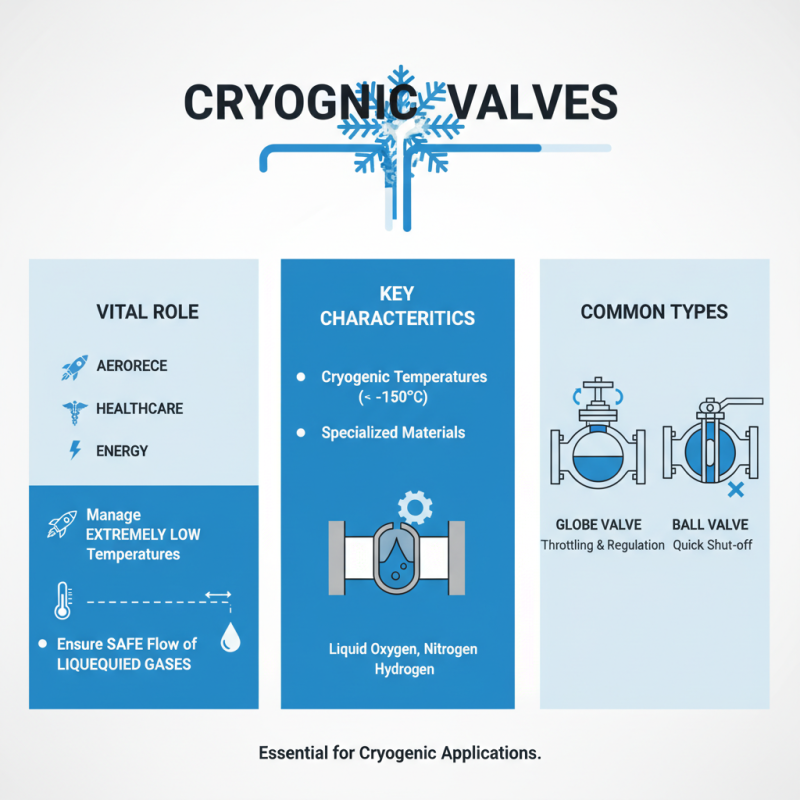

Cryogenic valves play a crucial role in various industries, such as liquefied natural gas and aerospace. These valves operate under extreme temperatures, often below -150 degrees Celsius. They ensure the safe and efficient flow of cryogenic fluids. Proper functioning is vital, as failures can lead to leaks or even catastrophic incidents.

Understanding the importance of these valves is essential for anyone involved in relevant sectors. They help maintain pressure, control flow, and prevent backflow in systems using cryogenic materials. Regular maintenance is necessary. Ignoring it can result in reduced performance or unexpected failures. Engineers often face challenges in selecting the right valves, as many factors must be considered, such as material compatibility and thermal expansion.

Moreover, the design of cryogenic valves can vary significantly. Some feature insulation to minimize thermal loss. Others may include unique seals to ensure tight closure under low temperatures. Balancing functionality with safety can be complex. There is always room for improvement in designs. Operators must remain vigilant and continually assess performance. Each situation presents new data for reflection.

Top 10 Cryogenic Valves You Need to Know About

This chart illustrates the distribution of various types of cryogenic valves based on their common applications and importance in the industry.

Types of Cryogenic Valves and Their Applications

Cryogenic valves play a vital role in various industries like aerospace, healthcare, and energy. They manage extremely low temperatures and ensure the safe flow of liquefied gases. Different types of cryogenic valves are essential for specific applications. For instance, globe valves are commonly used for throttling and regulating flow. On the other hand, ball valves are popular for their quick shut-off capabilities, often seen in storage systems.

A recent market report indicates that the global cryogenic valve market is expected to grow at a CAGR of 5.6% through 2025. This growth is driven by increasing demand for liquefied natural gas (LNG). In LNG plants, cryogenic valves are critical in maintaining safety and efficiency. The right choice of valve can prevent hazardous leaks and operational failures.

Tips: Always consider material compatibility. Some valves may not withstand harsh cryogenic conditions. Regular maintenance can also extend valve lifespan. Investing in high-quality valves can reduce long-term costs. Be aware, not all valves are adaptable; make sure to check specifications thoroughly. The right installation can be challenging but is essential for optimal performance.

Key Features to Consider When Selecting Cryogenic Valves

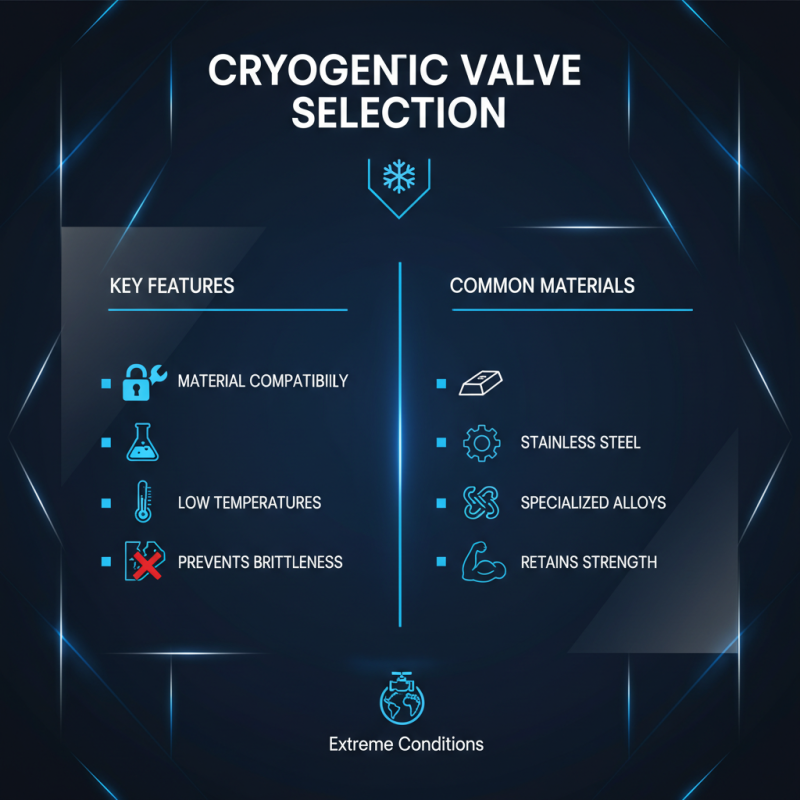

When selecting cryogenic valves, focus on key features. Material compatibility is crucial. Some materials can become brittle at low temperatures. Common choices include stainless steel and specialized alloys. These materials retain strength in extreme conditions.

Seal integrity matters too. Valves must ensure no leaks occur under pressure. Consider the type of sealing used. Teflon and elastomer seals are common. Their performance can vary, so scrutinize specifications carefully.

Tips: Always check the temperature range. Some valves perform poorly outside specified limits. It's wise to review usage scenarios, as cryogenic systems differ significantly. Additionally, durability is paramount in critical applications. Expect wear over time, so plan for replacements. Take time to understand your needs. A rushed decision can lead to costly mistakes.

Top 10 Recommended Cryogenic Valves and Their Specifications

Cryogenic valves are essential in various industrial applications, particularly in the storage and transport of liquefied gases. Understanding their specifications helps in selecting the right equipment. Among the top recommended cryogenic valves, key features include pressure ratings, temperature tolerances, and material quality.

For instance, certain valves operate at temperatures as low as -196°C. This is crucial for liquefied natural gas and liquid nitrogen applications. The design of the valve, including the stem and seat materials, influences performance under extreme conditions. Some valves maintain integrity at pressures exceeding 300 psi, which is critical in high-demand scenarios.

**Tip:** Always check compatibility with the medium being controlled. Valves that aren't compatible can lead to leaks or failures.

It's noteworthy that not all cryogenic valves are created equal. Some may fail under specific conditions. Continuous monitoring of valve performance is vital. Regular maintenance can predict potential failures before they happen. Reviewing industry reports suggests that a significant percentage of issues arise from neglecting this step.

**Tip:** Consider fail-safe designs. They can reduce risks and enhance safety in systems handling cryogenic substances.

Maintenance Best Practices for Cryogenic Valves

Maintaining cryogenic valves is crucial for efficient operation. Regular checks for leakage are essential. A small leak can lead to significant losses. Inspect the seals frequently to prevent wear and tear. Over time, materials can degrade under extreme temperatures. This process might not be obvious at first glance.

Valves should be cleaned carefully. Residues can affect performance. A simple wipe may not always suffice. Use appropriate cleaning solutions to avoid damage. Training staff is important too. They should recognize signs of potential failure. Documentation of maintenance activities aids in tracking performance.

Consider the environment as well. Extreme temperatures can affect valve life. Storage conditions matter too. Ensure valves are not exposed to unnecessary stress when not in use. Longevity of cryogenic valves can be improved with diligent care. Sometimes, problems arise despite best practices. Regular reviews can highlight areas needing attention. This ongoing process helps avoid costly issues in the future.

Top 10 Cryogenic Valves You Need to Know About

| Valve Type |

Material |

Temperature Range (°C) |

Pressure Rating (PSI) |

Applications |

| Ball Valve |

Stainless Steel |

-196 to 100 |

1500 |

Cryogenic Liquids, Gas Distribution |

| Globe Valve |

Alloy Steel |

-196 to 120 |

1000 |

Flow Control, Cryogenic Storage |

| Gate Valve |

Carbon Steel |

-196 to 90 |

1500 |

On/Off Service, LNG transport |

| Check Valve |

Bronze |

-196 to 80 |

600 |

Prevent Backflow, Cryogenic Systems |

| Butterfly Valve |

PVC |

-196 to 80 |

200 |

Flow Regulation, Venting |

| Diaphragm Valve |

PTFE |

-196 to 70 |

400 |

Isolation, Cryogenic Testing |

| Pressure Relief Valve |

Stainless Steel |

-196 to 100 |

3000 |

Safety, LNG Systems |

| Angle Valve |

Brass |

-196 to 50 |

600 |

Pipeline Control, Cryogenic Transport |

| Solenoid Valve |

Aluminium |

-196 to 80 |

1000 |

Automatic Control, Cryogenic Applications |

| Safety Valve |

Stainless Steel |

-196 to 150 |

2000 |

Safety, Industrial Cryogenics |

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.