7 Unique Features That Make the Best Butterfly Valve Stand Out

In recent years, the butterfly valve has emerged as a critical component in fluid control systems across various industries, from water treatment to oil and gas. According to a report from Market Research Future, the global butterfly valve market is expected to reach $9 billion by 2024, reflecting a compound annual growth rate (CAGR) of 7.5%. This growth is largely attributed to the valve's unique features, such as its lightweight design, space-saving construction, and ability to handle a wide range of temperatures and pressures. As industries seek more efficient and cost-effective solutions for flow regulation, the best butterfly valve designs have begun to stand out for their innovative functionalities. This blog will explore the seven unique features that set these standout butterfly valves apart, highlighting how they deliver enhanced performance, reliability, and value in today’s dynamic industrial landscape.

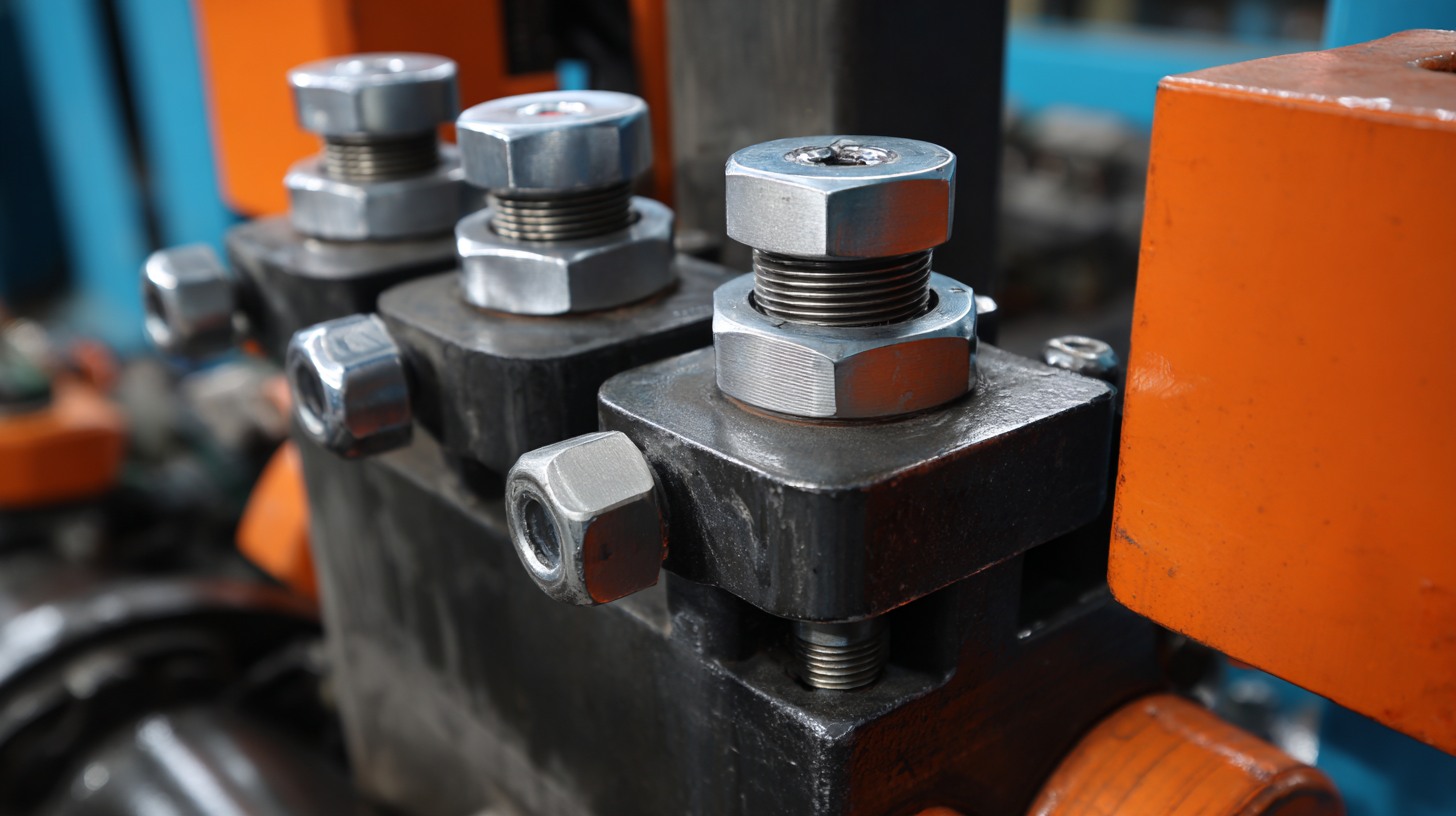

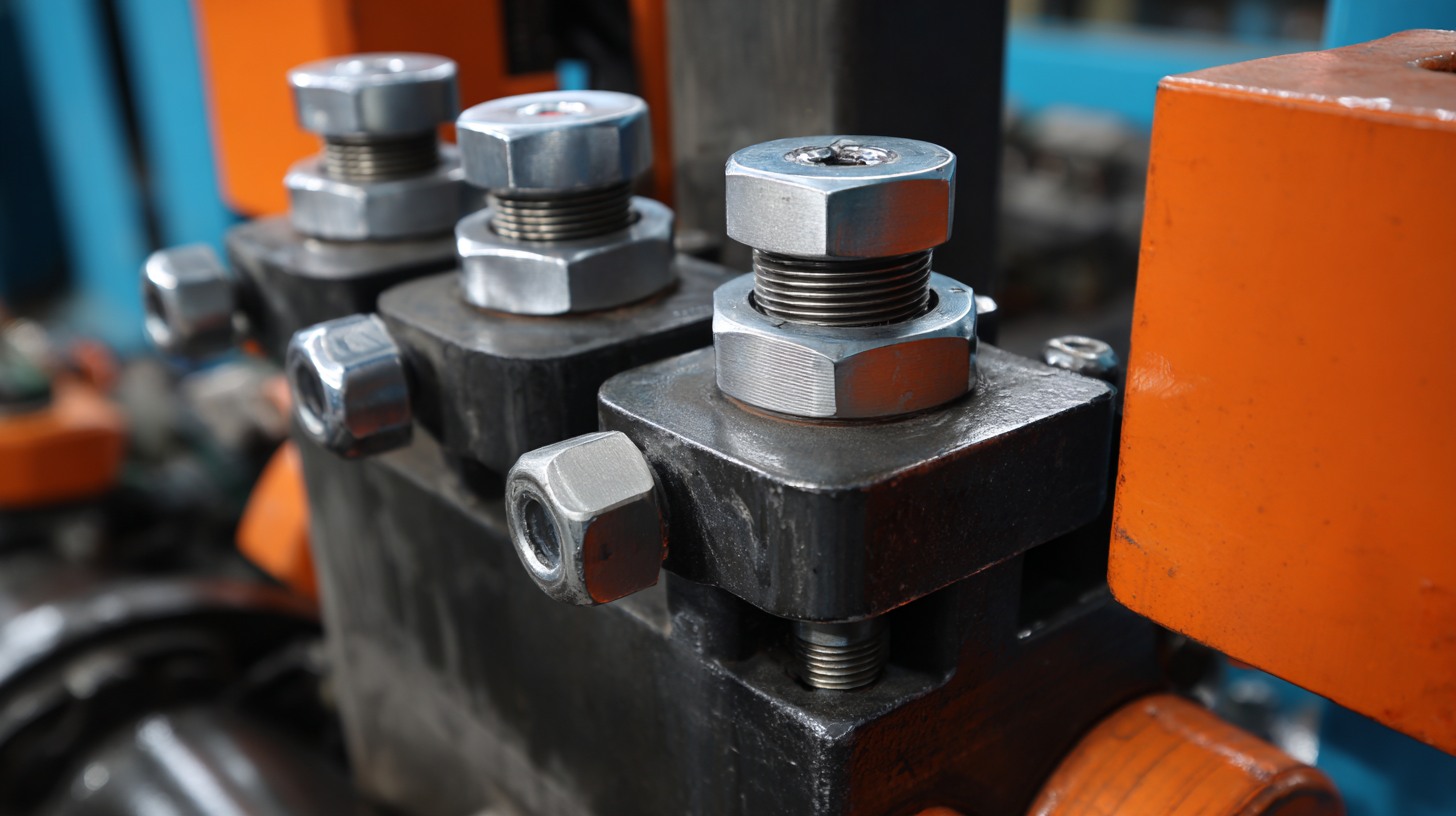

Unmatched Durability: The High-Quality Materials Behind Superior Butterfly Valves

When it comes to selecting the best butterfly valves, one of the most critical factors to consider is durability, primarily determined by the quality of materials used in their construction. According to a report by the Valve Manufacturers Association, valves made from high-grade castings and materials like stainless steel and nickel alloys tend to exhibit significantly higher resistance to corrosion and wear. This leads to extended lifespans—often exceeding 20 years even in challenging environments.

Furthermore, the type of seal used in butterfly valves plays a pivotal role in their durability. Research indicates that valves employing advanced elastomeric and fluoropolymer seals can withstand harsh chemicals and extreme temperatures, enhancing their reliability in various applications—ranging from water treatment to chemical processing. A survey by the American Society of Mechanical Engineers revealed that up to 75% of valve failures can be attributed to seal degradation, underscoring the importance of selecting valves that leverage cutting-edge sealing technologies. Investing in high-quality butterfly valves not only ensures unmatched performance but can also generate significant cost savings through reduced maintenance and replacement needs over time.

7 Unique Features That Make the Best Butterfly Valve Stand Out - Unmatched Durability: The High-Quality Materials Behind Superior Butterfly Valves

| Feature |

Description |

Material |

Durability Rating |

| Corrosion Resistance |

Resistant to rust and chemical wear, ensuring longevity. |

Stainless Steel |

Excellent |

| Temperature Tolerance |

Can withstand high and low temperatures without losing functionality. |

Bronze |

Very Good |

| Sealing Performance |

Provides tight shut-off, preventing leaks. |

EPDM Rubber |

Excellent |

| Lightweight Design |

Easier to handle and install compared to traditional valves. |

Composite Materials |

Good |

| Maintenance-Free Operation |

Designed to require minimal upkeep over time. |

Polymer Coatings |

Very Good |

| Versatility |

Suitable for a wide range of applications in various industries. |

Various Alloys |

Excellent |

| Cost-Effectiveness |

Provides long-term savings due to reduced maintenance and replacement needs. |

Carbon Steel |

Good |

Innovative Design Features That Enhance Efficiency and Performance

In the realm of fluid control systems, butterfly valves have emerged as critical components, particularly due to their innovative design features that enhance both efficiency and performance. For instance, the use of lightweight materials and streamlined constructions allows for reduced flow resistance. According to a report by MarketsandMarkets, the global butterfly valve market is expected to reach $4.4 billion by 2025, driven by the increasing demand for these efficient solutions in water treatment and oil and gas applications.

One standout feature that characterizes the best butterfly valves is the patented seat design, which minimizes leakage and maximizes pressure capability. Advanced technologies such as digital actuation and integrated flow monitoring not only improve control but also provide real-time data for better decision-making in process management. Research suggests that optimizing these design aspects can significantly lower operational costs, with potential savings of up to 30% in energy consumption related to valve operation. This alignment of cutting-edge design and operational efficiency marks a shift towards more sustainable industrial practices fuelled by innovation in butterfly valve technology.

Precision Engineering: Ensuring Optimal Functionality in Harsh Conditions

Precision engineering is critical in ensuring the functionality of butterfly valves, especially in demanding environments. As industries continue to face tougher operational conditions, the need for reliable and durable components grows. A recent industry report indicates that machinery and components designed with precision engineering can enhance performance by up to 30%, especially when exposed to extreme temperatures and pressures. This highlights the importance of meticulous design and manufacturing processes that leverage advanced materials and coatings to withstand harsh conditions.

In particular, the integration of smart technologies, such as IoT sensors, into industrial components is transforming how we monitor and manage operational efficiency. Precision-engineered components equipped with smart sensors can provide real-time data on their condition, enabling predictive maintenance and reducing downtime. For example, data indicates that facilities utilizing smart sensors can experience up to 25% cost savings through optimized maintenance and operational adjustments. This level of precision not only ensures optimal functionality but also enhances the overall reliability of critical systems, including butterfly valves, in various industrial applications.

Customization Options: Tailoring Butterfly Valves for Specific Industrial Needs

When it comes to butterfly valves, customization is key in meeting the diverse requirements of various industrial applications. Tailoring these valves to specific needs can enhance performance, improve efficiency, and ensure optimal flow control. Manufacturers now offer a range of customization options, allowing industries to select materials, sizes, pressure ratings, and actuator types that best align with their operational demands. This level of personalization ensures that each butterfly valve functions effectively within its assigned environment, whether it be high-temperature processes, corrosive substances, or high-pressure systems.

Moreover, customization extends beyond just technical specifications. Aesthetic options may also be considered, especially in applications where visibility and environmental factors come into play. For instance, valves can be painted or coated to resist harsh conditions while maintaining aesthetic integrity. Furthermore, software integration for smart valve technology allows for real-time monitoring and adjustments, which caters to modern industries' need for efficiency and precision. By leveraging these customization options, businesses can significantly enhance their workflow and maintain high standards of safety and reliability.

Global Expertise: How Chinese Manufacturing Leads the Butterfly Valve Market

Chinese manufacturing has emerged as a dominant force in the global butterfly valve market, accounting for over 30% of the total market share as of 2022, according to a recent report by MarketsandMarkets. This leadership is attributed to China's robust supply chain, advanced manufacturing technologies, and cost-effective production processes. The country has invested significantly in research and development, resulting in butterfly valves that not only meet international standards but often exceed them in terms of durability and performance.

One of the unique features of Chinese-manufactured butterfly valves is their adaptability to various industrial applications, including water treatment, oil and gas, and HVAC systems. This versatility is supported by the production of valves in a wide range of materials and sizes, catering to diverse environmental conditions. Additionally, Chinese companies are increasingly focusing on eco-friendly manufacturing practices, which is an essential consideration for many industries today. With a continuous push towards innovation and sustainability, China's role in the butterfly valve market is likely to strengthen, setting new benchmarks for efficiency and reliability.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.