Unlocking Global Excellence in Best Gate Valves with Chinese Quality Manufacturing

The global gate valves market is projected to reach a value exceeding USD 11 billion by 2025, driven by the increasing demand across various industries such as water supply, oil and gas, and power generation. As these sectors require reliable and efficient flow control solutions, the significance of high-quality gate valves cannot be overstated. Chinese manufacturers have emerged as key players in this arena, leveraging advanced manufacturing techniques and stringent quality control measures to produce gate valves that meet international standards. The emphasis on innovation and adherence to best practices positions China as a hub for gate valve production, enabling companies worldwide to access superior products that enhance operational efficiency and safety. This guide explores the pathways through which Chinese quality manufacturing is unlocking global excellence in gate valves, underscoring the critical role these components play in modern industrial applications.

The Importance of Gate Valves in Global Industries

Gate valves play a pivotal role in various global industries, serving as critical components that control fluid flow in pipelines and systems. Their essential function lies in ensuring the efficient operation of water, oil, gas, and chemical transportation. By providing a reliable shut-off mechanism, gate valves prevent leakages and maintain system pressure, which are crucial for safety and efficiency. Many sectors, including energy, manufacturing, and construction, rely heavily on these valves to manage resource distribution and maintain operational integrity.

In today’s global market, the demand for high-quality gate valves has surged, prompting manufacturers to prioritize quality assurance and innovation. Chinese manufacturing has emerged as a key player in this arena, leveraging advanced technology and rigorous quality control processes. With a focus on producing gate valves that meet international standards, Chinese manufacturers are enhancing their reputation for quality while meeting the increasing global demands. As industries continue to evolve, the importance of reliable gate valves remains paramount, underscoring the need for exceptional manufacturing practices that ensure performance and longevity in critical applications.

Understanding Chinese Quality Standards in Valve Manufacturing

Chinese manufacturing has made significant strides in quality standards, particularly in the valve industry. The emphasis on certifications such as CQC and CCAP showcases the commitment of Chinese manufacturers to adhere to international quality benchmarks. CQC certification, a voluntary standard, plays a crucial role in ensuring that products meet safety and performance requirements. This is particularly relevant for gate valves, which are essential components in various industrial applications. As a result, manufacturers are not only improving their products but also enhancing their credibility in global markets.

Moreover, recent advancements in valve technology, including breakthroughs in nuclear valve manufacturing, underscore China's dedication to innovation. Such developments highlight the capability of Chinese firms to compete on a global scale by providing high-quality, high-performing valves designed for demanding conditions. With an increasing number of Chinese manufacturers seeking to expand their presence internationally, understanding these quality standards and certifications becomes imperative for gaining a foothold in the competitive valve market. This focus on quality manufacturing aligns with the broader trend of transforming traditional industries to meet modern demands and expectations worldwide.

Key Features That Define Best Gate Valves

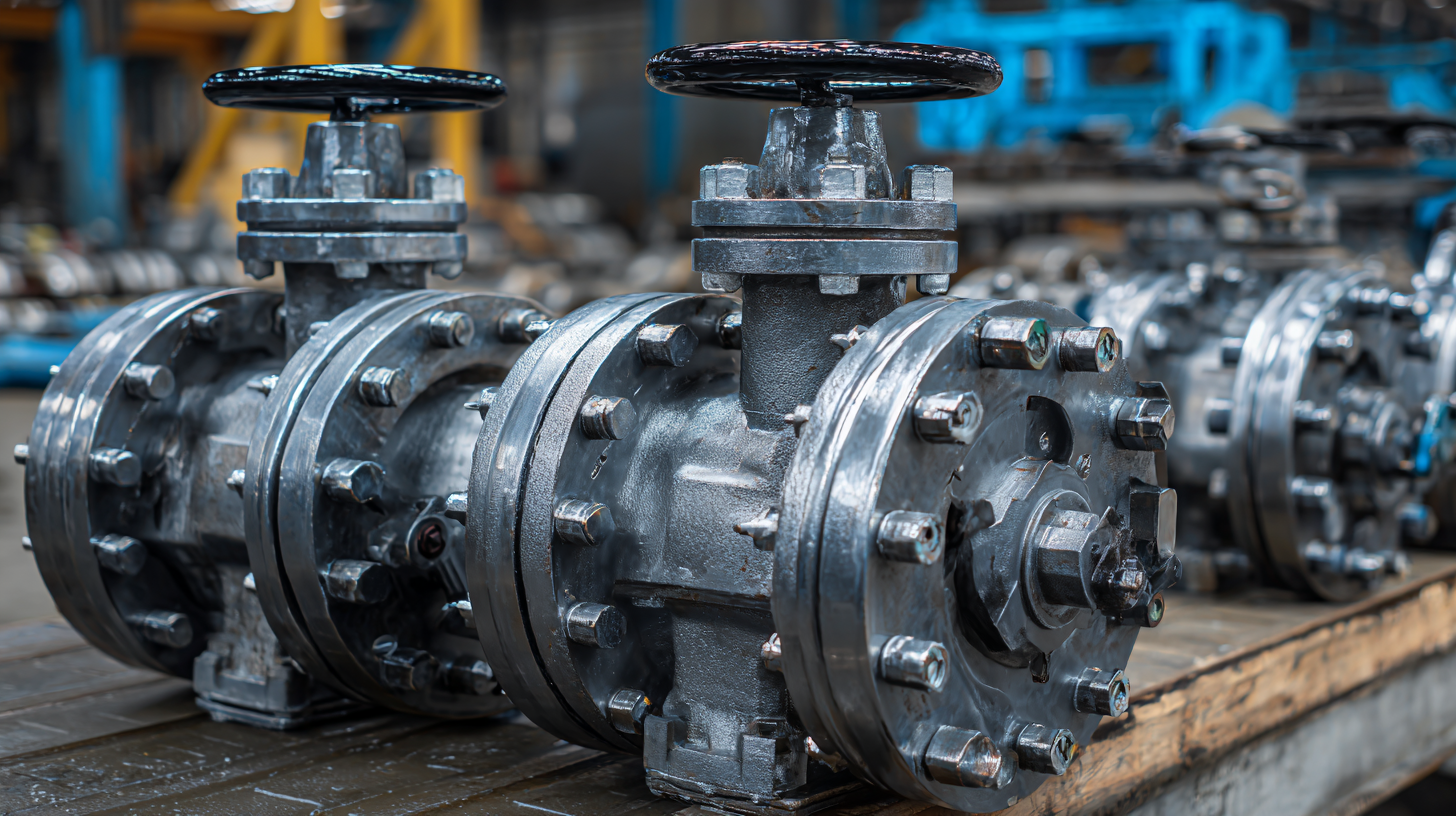

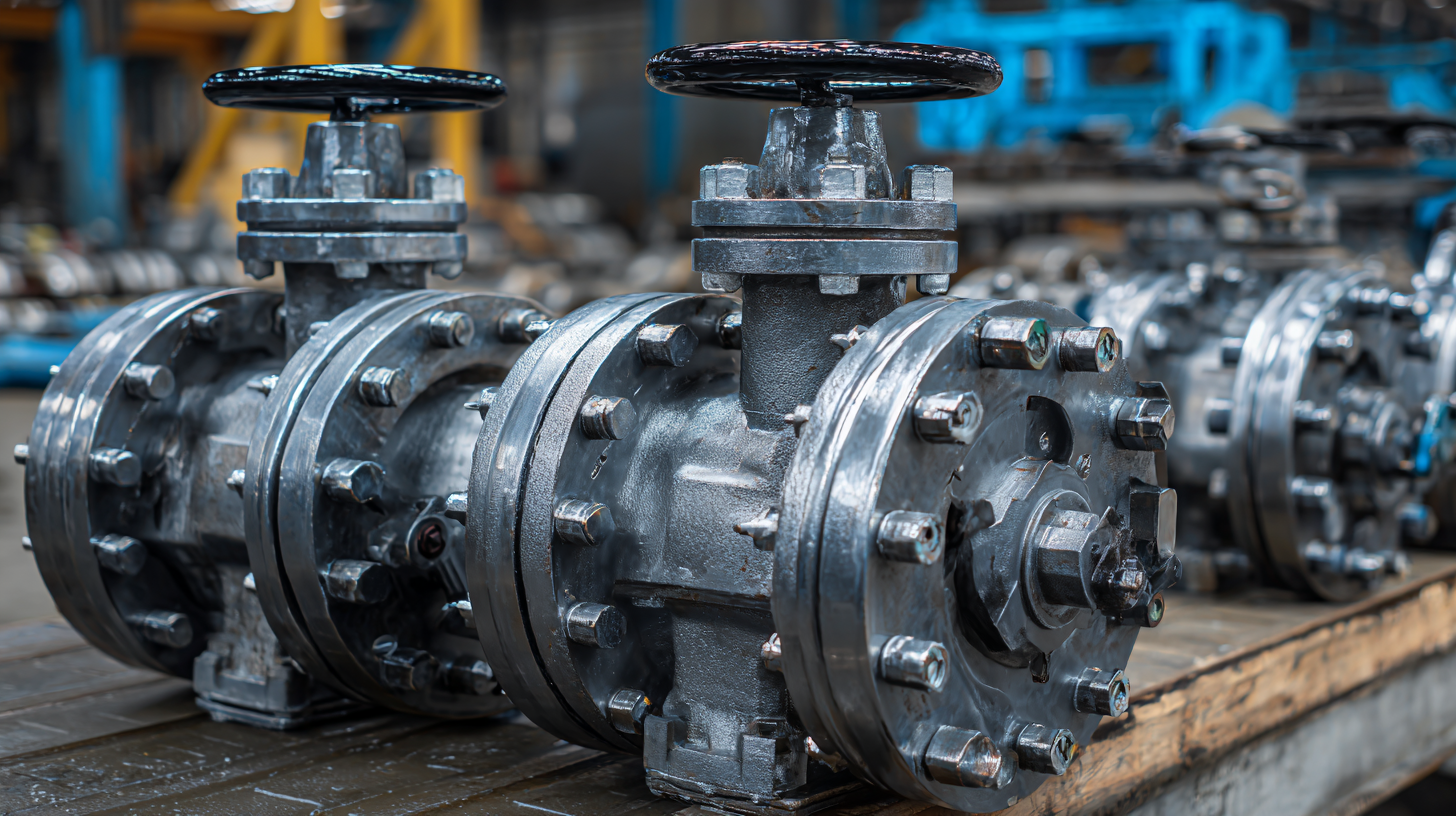

When it comes to gate valves, the quality of manufacturing plays a crucial role in ensuring durability and performance. Chinese manufacturers have rapidly gained recognition for delivering some of the best gate valves in the market. Key features that define top-tier gate valves include material quality, design precision, and operational reliability. High-quality materials like cast iron and stainless steel are essential for corrosion resistance and longevity, ensuring that these valves can withstand challenging environments.

Tips for selecting the best gate valves include checking for compliance with international standards and certifications. It’s important to look for valves that have been rigorously tested for performance under various pressures and temperatures. Additionally, consider the design features, such as the type of seat and seal, which can significantly impact the valve's ability to prevent leaks and maintain efficiency over time.

Furthermore, understanding the functional parameters such as flow capacity and pressure rating can help in choosing the right valve for specific applications. Always prioritize manufacturers who offer after-sales support and comprehensive warranties, as these factors contribute significantly to the overall value of the valve and peace of mind for the end-user.

Innovative Manufacturing Techniques for Enhanced Performance

The manufacturing of gate valves has seen significant advancements through innovative techniques that enhance performance while ensuring durability. One prominent method includes the use of Computer Numerical Control (CNC) machining, which allows for precise manufacturing tolerances of less than 0.01 mm. According to a recent report by Market Research Future, the demand for high-quality gate valves is projected to grow at a CAGR of 5.6% from 2021 to 2027, underscoring the industry's shift towards technologies that prioritize efficiency and reliability.

Incorporating advanced materials such as duplex stainless steel and high-performance polymers has further revolutionized gate valve production. These materials not only offer better corrosion resistance but also improve the overall lifespan of the valves, reducing maintenance costs significantly. A report from ResearchAndMarkets states that the global gate valve market is expected to reach $9.5 billion by 2026, driven largely by innovations in manufacturing processes.

**Tips:** When selecting gate valves, consider manufacturers that utilize advanced manufacturing techniques to ensure optimum performance. Additionally, look for those that provide detailed certification on the materials used, as this can significantly affect the valve's durability and reliability in critical applications. Always consult the latest market trends to make informed decisions about your procurement strategy.

Unlocking Global Excellence in Best Gate Valves with Chinese Quality Manufacturing - Innovative Manufacturing Techniques for Enhanced Performance

| Dimension |

Material |

Application |

Pressure Rating (PN) |

Temperature Range (°C) |

| DN50 |

Cast Iron |

Water Supply |

16 |

-10 to 80 |

| DN100 |

Ductile Iron |

Gas Pipeline |

25 |

-10 to 100 |

| DN150 |

Stainless Steel |

Chemical Processing |

40 |

-20 to 200 |

| DN200 |

Carbon Steel |

Oil & Gas |

63 |

-30 to 150 |

| DN300 |

Bronze |

Marine Applications |

16 |

0 to 90 |

Comparative Analysis: Chinese vs. Global Gate Valve Production

The comparative analysis of Chinese versus global gate valve production reveals significant insights into manufacturing excellence and market dynamics. Chinese manufacturers have emerged as formidable players in the gate valve sector, leveraging advanced production technologies and economies of scale. This has allowed them to offer high-quality products at competitive prices, making significant inroads into international markets.

In contrast, global manufacturers often emphasize premium quality and specialization in their offerings. Companies outside China typically focus on niche applications that require specialized gate valves, thus ensuring their products meet stringent international standards. However, the rapid evolution of Chinese manufacturing capabilities suggests that the gap in quality is narrowing. The ongoing investment in R&D and quality assurance processes in China further enhances their position, potentially reshaping the competitive landscape in the gate valve market. The implications of this shift are noteworthy for stakeholders, signaling a need for global manufacturers to innovate and adapt in order to maintain market relevance amidst rising Chinese competition.

Comparative Analysis of Gate Valve Production: Chinese vs. Global Manufacturing

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.