Unlocking Precision: Discover the Best Actuator Valves from China's Leading Manufacturing Factory

In the ever-evolving landscape of industrial automation, actuator valves play a crucial role in enhancing operational efficiency and precision.

According to recent industry reports, the global actuator valve market is projected to reach USD 12.5 billion by 2025, growing at a CAGR of 6.8% from 2020 to 2025.

This growth is driven by the increasing demand for automation in manufacturing processes, necessitating the use of sophisticated actuator valve solutions for optimal control of flow and pressure.

As China stands at the forefront of manufacturing innovation, understanding the offerings from its leading factories becomes paramount for industry professionals looking to unlock precision in their operations.

This blog will guide you through some of the best actuator valves available, providing valuable insights and tips to enhance your selection process, ensuring that you harness the full potential of these essential components.

Understanding the Importance of Actuator Valves in Modern Industry Applications

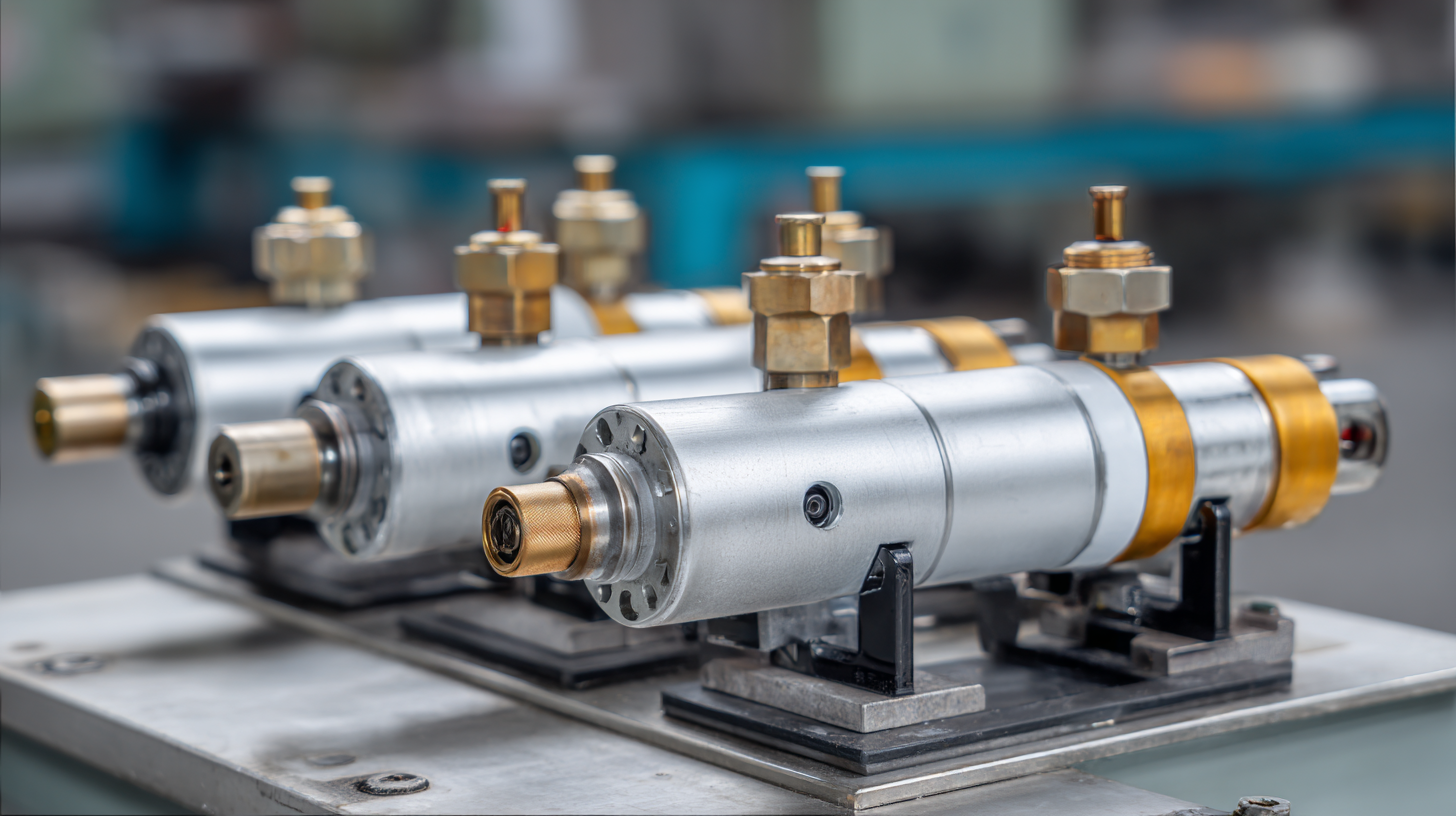

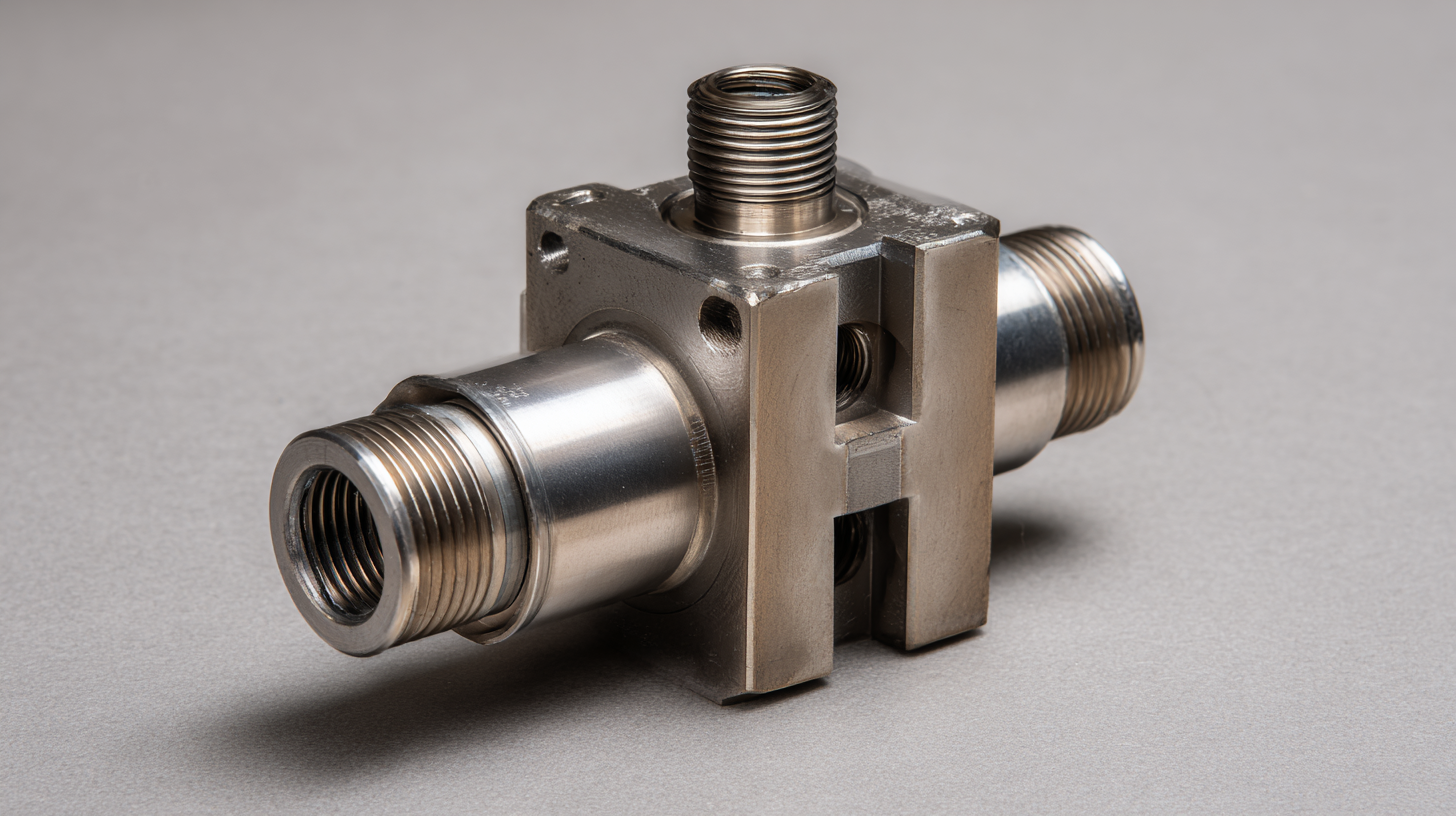

Actuator valves are essential components in modern industrial applications, serving crucial roles in controlling the flow of fluids and gases within various systems. These valves are typically powered by electric, pneumatic, or hydraulic actuators, allowing for precise and efficient control over processes in sectors like manufacturing, oil and gas, water treatment, and chemical processing. Their ability to respond to automation systems and remote commands significantly enhances operational efficiency, reducing the need for manual intervention and minimizing the chances of human error.

Actuator valves are essential components in modern industrial applications, serving crucial roles in controlling the flow of fluids and gases within various systems. These valves are typically powered by electric, pneumatic, or hydraulic actuators, allowing for precise and efficient control over processes in sectors like manufacturing, oil and gas, water treatment, and chemical processing. Their ability to respond to automation systems and remote commands significantly enhances operational efficiency, reducing the need for manual intervention and minimizing the chances of human error.

In an era where industries strive for increased productivity and enhanced safety, the integration of actuator valves not only streamlines operations but also offers flexibility in system design. For instance, in a manufacturing plant, actuator valves can be programmed to respond to real-time data, optimizing resource usage and maintaining consistent product quality. Moreover, these valves are designed to withstand harsh environments, ensuring reliability and longevity, key attributes that resonate with industry demands for sustainability and cost-effectiveness. As industries continue to evolve, the importance of selecting the best actuator valves from reputable manufacturing sources becomes increasingly vital to maintaining competitive advantage and operational excellence.

Key Features to Look for in High-Quality Actuator Valves from China

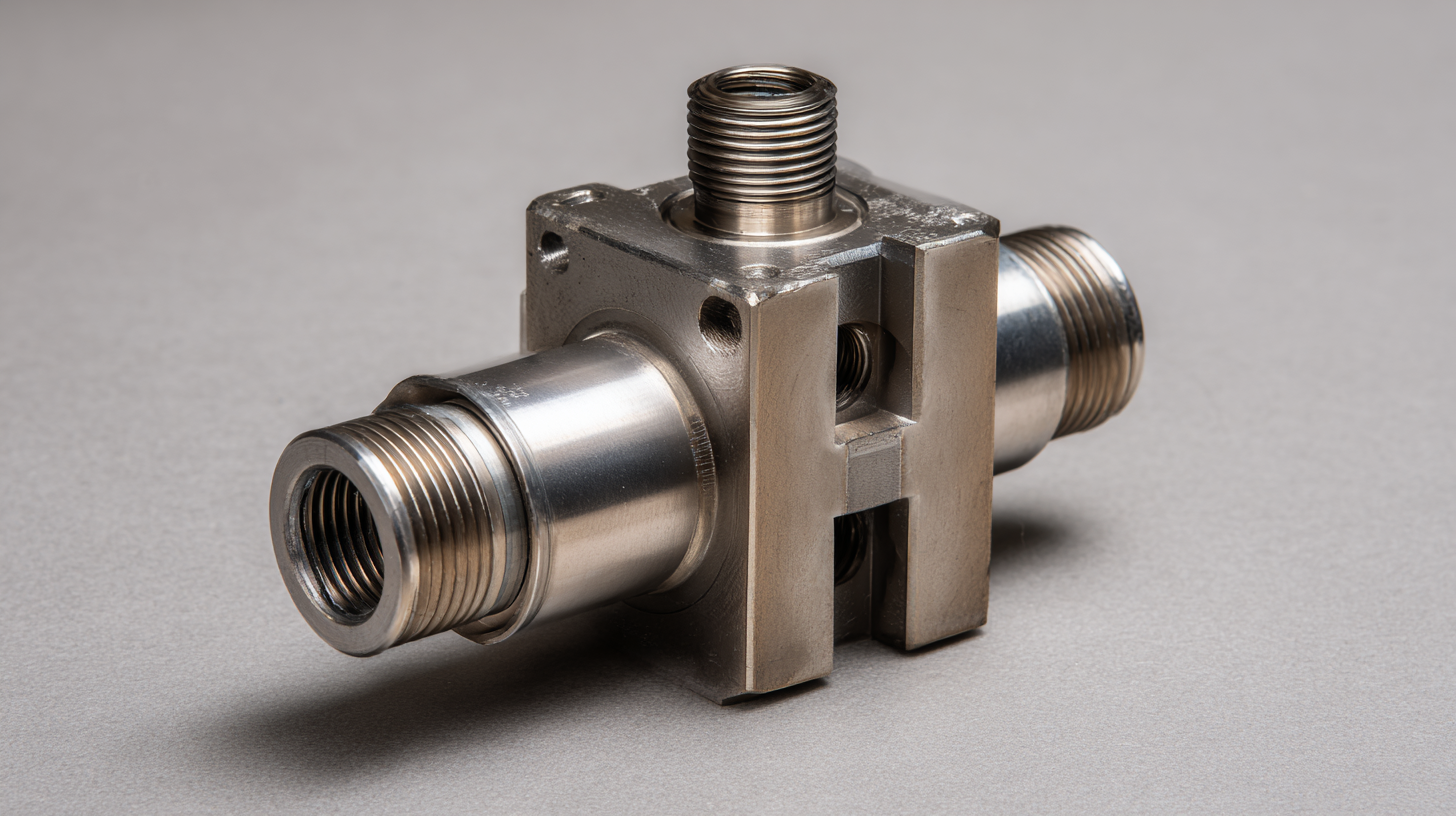

When considering the best actuator valves from China's leading manufacturing factories, it is crucial to focus on key features that exemplify high quality.

One of these features is precision control, which ensures that the actuator valves respond accurately to inputs, thereby achieving optimal performance in various applications.

High-quality actuator valves are often designed with advanced materials that resist wear and corrosion, ensuring longevity and reducing the need for frequent replacements.

A robust build quality ultimately contributes to increased operational efficiency and reduced downtime.

Another critical aspect to look for is compatibility with various control systems.

The best actuator valves should support seamless integration with existing infrastructure, providing versatility for end-users.

Additionally, consider the level of automation and smart features, as modern actuator valves increasingly come equipped with technology that enables remote monitoring and control.

Such innovations not only enhance functionality but also improve the overall operational efficiency of industrial processes.

As seen in the steady growth of the actuator valve market, these features are essential for maintaining competitiveness and meeting the demands of today’s dynamic industrial landscape.

Comparative Analysis: China's Leading Actuator Valve Manufacturers and Their Innovations

In the evolving landscape of actuator valves, manufacturers in China are pushing the boundaries of innovation to meet the growing demands of various industries. A recent report indicates that the global aerosol valves market, which includes actuator valves, was valued at approximately USD 1.64 billion in 2024 and is projected to grow at a compound annual growth rate (CAGR) of 6.6% from 2025 to 2030. This growth underscores the critical role actuator valves play in enhancing system efficiency and energy consumption, particularly in fields such as electro-hydraulic systems.

Leading actuator valve manufacturers in China are at the forefront of technological advancements, introducing solutions that optimize power consumption and improve position control. Recent studies highlight new methodologies, such as using cylinder bypass techniques and nonlinear model predictive control (NN-MPC), which significantly enhance the energy efficiency and positional accuracy of electro-hydraulic systems. These innovations not only cater to the increasing demand for precision in industrial applications but also align with global trends towards sustainable and energy-efficient solutions. The comparative analysis of these manufacturers showcases their commitment to meeting market needs while driving the industry forward.

Unlocking Precision: Discover the Best Actuator Valves from China's Leading Manufacturing Factory

| Manufacturer |

Type of Actuator Valve |

Innovations |

Material Used |

Average Lead Time (Days) |

| Manufacturer A |

Electric Actuator |

Smart Control System |

Stainless Steel |

30 |

| Manufacturer B |

Pneumatic Actuator |

Enhanced Leakage Prevention |

Aluminum Alloy |

25 |

| Manufacturer C |

Hydraulic Actuator |

Adaptive Pressure Control |

Carbon Steel |

40 |

| Manufacturer D |

Smart Actuator |

IoT Connectivity |

Plastic Composite |

20 |

| Manufacturer E |

Electric Actuator |

High Efficiency Design |

Bronze |

35 |

Industry Trends: The Growth of Actuator Valve Market and China's Role in It

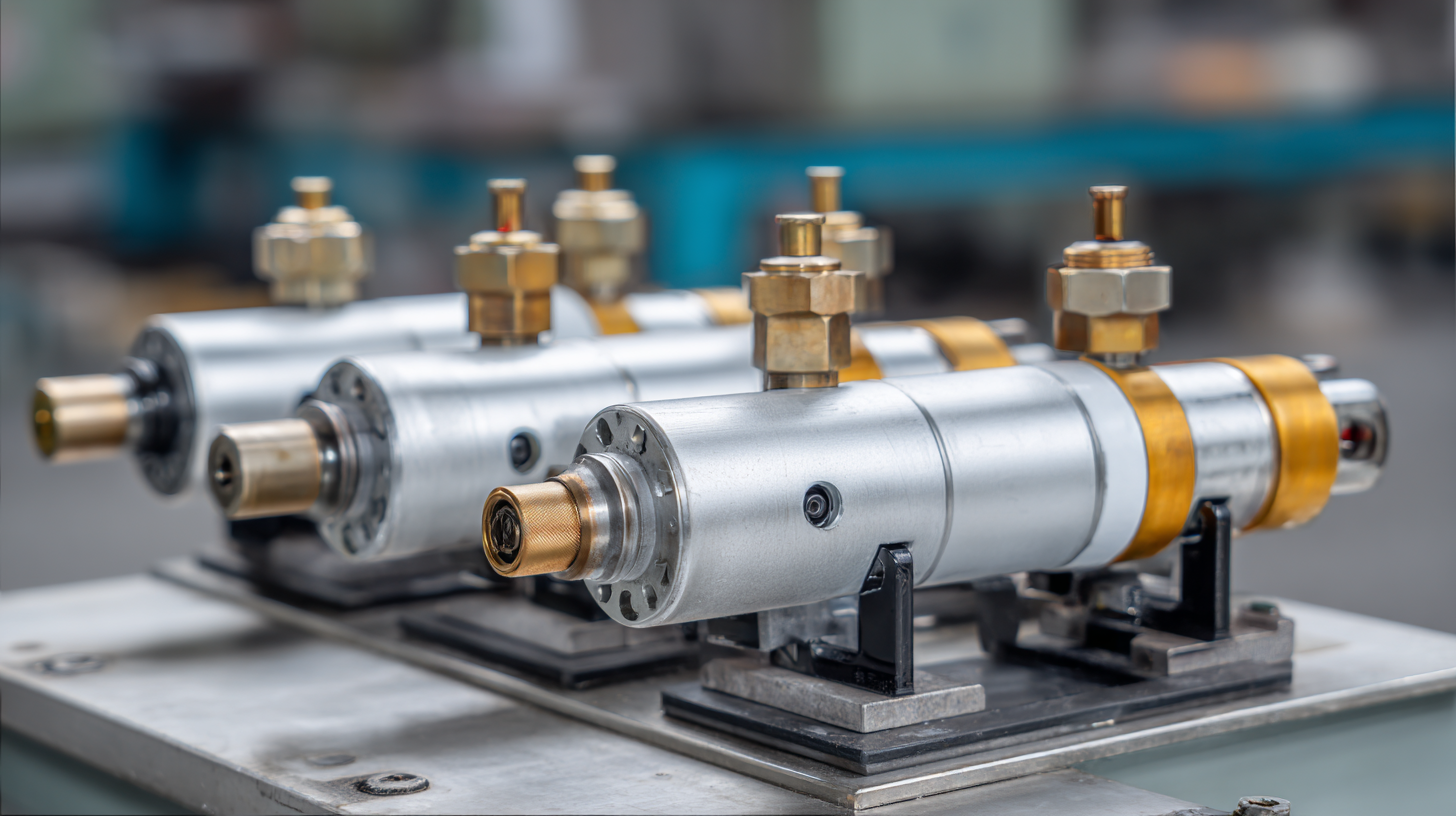

As the actuator valve market continues to expand, China's role is becoming increasingly significant. Over the past few years, the demand for precise control in various industrial applications has surged, driving manufacturers to enhance their offerings. China's leading manufacturing factories are leveraging advanced technology and innovative designs to produce actuator valves that meet diverse industry needs.

Tip: When selecting actuator valves, consider the compatibility of materials with your specific application to ensure durability and performance. High-quality manufacturing processes can greatly influence the longevity and reliability of these components.

Moreover, the growth of automation in sectors such as oil and gas, water treatment, and pharmaceuticals is propelling the actuator valve market forward. Chinese manufacturers are at the forefront, adopting international standards to deliver high-performance products. This proactive approach not only boosts their competitive edge but also helps meet global sustainability goals.

Moreover, the growth of automation in sectors such as oil and gas, water treatment, and pharmaceuticals is propelling the actuator valve market forward. Chinese manufacturers are at the forefront, adopting international standards to deliver high-performance products. This proactive approach not only boosts their competitive edge but also helps meet global sustainability goals.

Tip: Always assess the certifications and standards compliance of potential actuator valve suppliers to ensure they align with your project requirements and industry regulations. Doing so can minimize risks and enhance operational efficiency.

How to Choose the Right Actuator Valve for Your Specific Needs and Applications

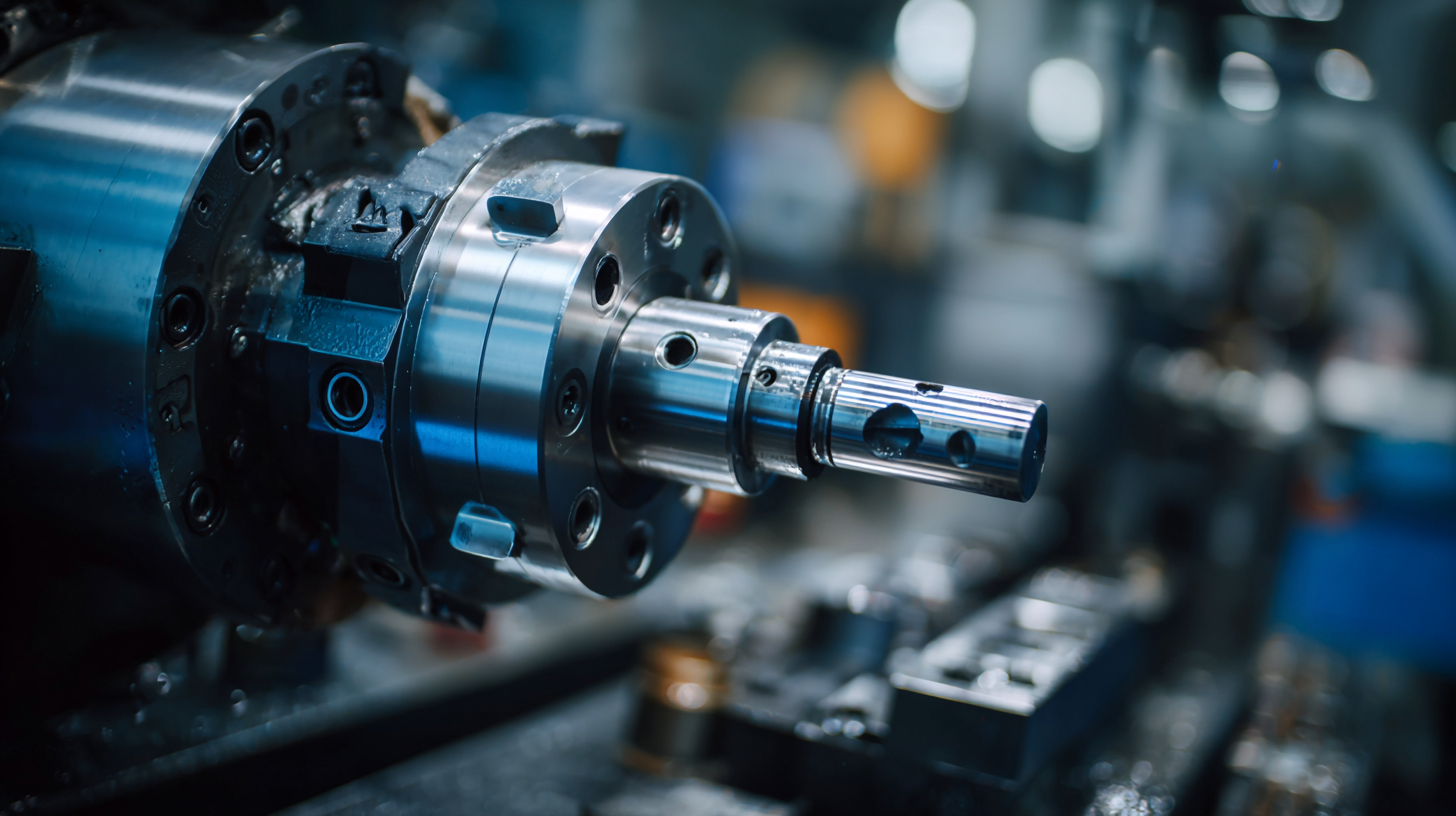

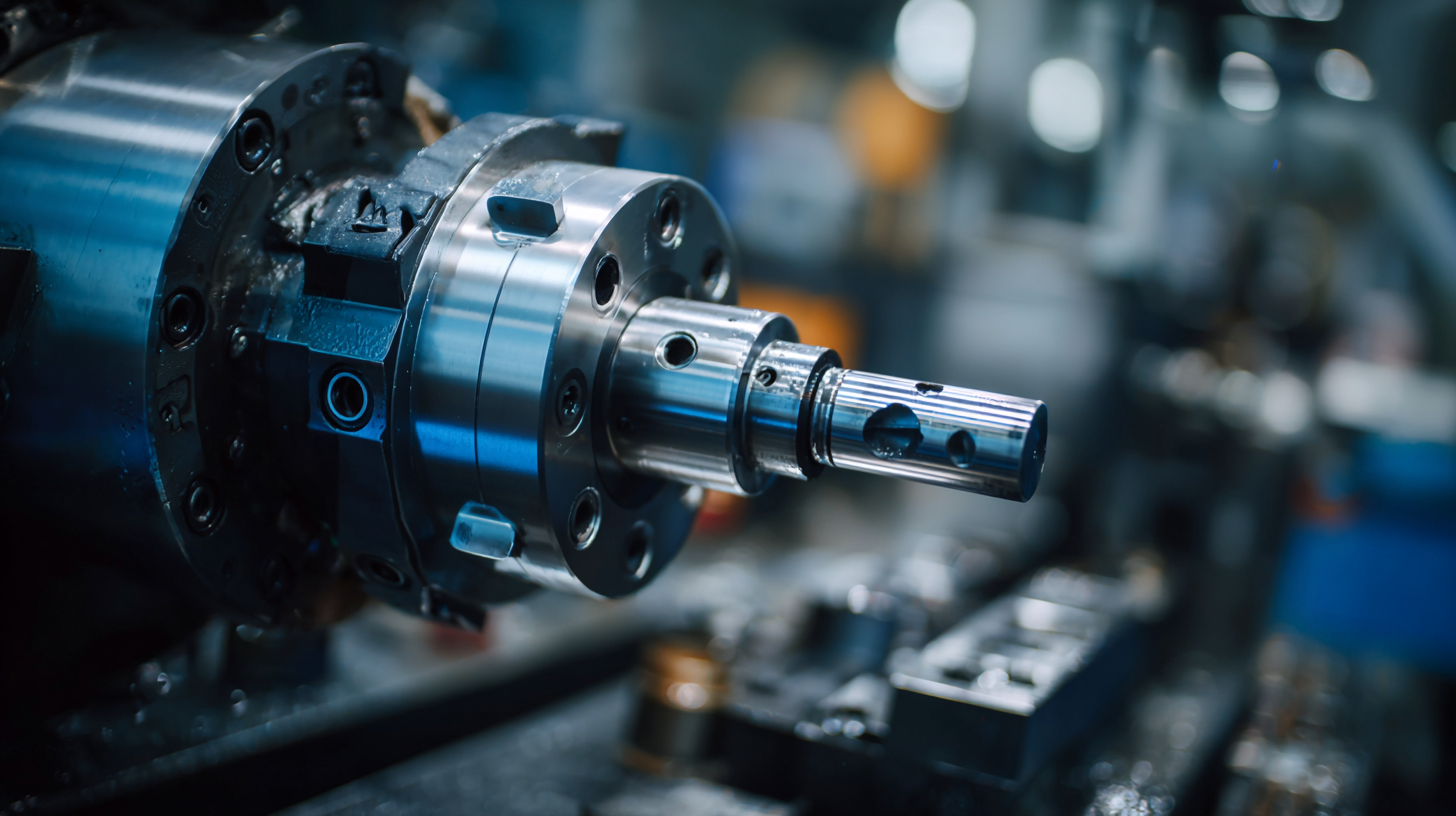

When selecting the right actuator valve for your specific needs and applications, it's essential to consider various factors that influence performance and compatibility. Actuator valves play a crucial role in automation, controlling the flow of liquids and gases with precision. The choices available in the market are vast, but understanding your unique requirements can help streamline the selection process. Factors like pressure rating, flow characteristics, and the type of actuator—whether electric, pneumatic, or hydraulic—should be assessed to ensure optimal performance in your system.

As technology advances, like the recent developments in wearable haptic devices that simulate touch for immersive experiences, similar innovations are influencing actuator valve designs. The integration of smart technologies into actuator valves not only enhances their efficiency but also provides real-time feedback for better control in various applications. By keeping an eye on such trends and understanding the interplay between technology and function, you can make informed decisions that align with the latest advancements in your industry. Ultimately, the key is to align the actuator valve's capabilities with your specific operational needs, setting the stage for improved performance and reliability.

Unlocking Precision: Actuator Valve Performance Comparison

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

© Copyright 2020 Tianjin Tanghaidongyang Valve Co., Ltd. All Rights Reserved.

Moreover, the growth of automation in sectors such as oil and gas, water treatment, and pharmaceuticals is propelling the actuator valve market forward. Chinese manufacturers are at the forefront, adopting international standards to deliver high-performance products. This proactive approach not only boosts their competitive edge but also helps meet global sustainability goals.

Moreover, the growth of automation in sectors such as oil and gas, water treatment, and pharmaceuticals is propelling the actuator valve market forward. Chinese manufacturers are at the forefront, adopting international standards to deliver high-performance products. This proactive approach not only boosts their competitive edge but also helps meet global sustainability goals.